The Benefits of a 10 Ton Gantry Crane for Your Operations:

- Increased Lifting Capacity: A 10 ton gantry crane can handle heavy loads with ease, reducing the need for multiple lifts and minimizing the risk of damage to materials. This capacity allows for more streamlined workflows.

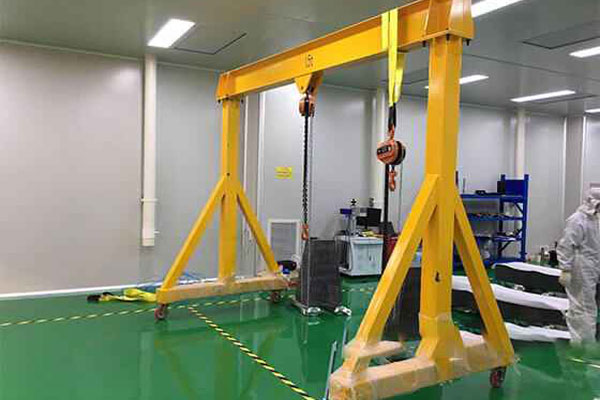

- Enhanced Mobility: Many 10 ton gantry crane are mobile, allowing for easy relocation within a facility. This flexibility enables quick adjustments to workspaces, facilitating better use of floor space and reducing downtime.

- Improved Safety: Gantry cranes are designed with safety features that reduce the risk of accidents. Their stability and precision in lifting help minimize the potential for injuries to operators and nearby workers.

- Versatile Applications: These 10 ton gantry crane can be adapted for various tasks across different industries, from manufacturing and construction to shipping and maintenance. This versatility makes them a valuable investment for diverse operational needs.

- Cost-Effectiveness: Investing in a 10 ton gantry crane can lead to cost savings over time. By improving lifting efficiency and reducing manual labor, businesses can lower operational costs while increasing productivity.

- Streamlined Workflow: The ability to quickly and easily lift and move heavy loads minimizes delays in production processes. This efficiency can lead to faster turnaround times and improved overall productivity.

Choosing the Right 10 Ton Gantry Crane:

1. Type of Gantry CraneFixed vs. Adjustable: Fixed 10 ton gantry crane have set height and span, while adjustable ones can be modified based on your needs.

Portable vs. Stationary: If mobility is crucial, opt for a portable model. Stationary models provide more stability for heavier loads.

2. Material and ConstructionFrame Material: Common materials include steel and aluminum. Steel is durable and suitable for heavy-duty tasks, while aluminum is lightweight and portable.

Welding and Design Quality: Check the welding quality and overall design to ensure strength and durability.

3. Lifting MechanismHoist Type: Choose between electric, pneumatic, or manual hoists based on your operational needs and environment.

Speed and Control: Look for 10 ton gantry crane that offer variable speed control for precision lifting and lowering.

4. Safety FeaturesOverload Protection: Ensure the 10 ton gantry crane has systems in place to prevent lifting loads beyond its capacity.

Brakes and Emergency Stops: Look for reliable braking systems and easy-to-access emergency stop controls.

5. Ease of Assembly and DisassemblyIf you need to move or store the gantry crane frequently, consider models designed for easy assembly and disassembly.

6. Cost ConsiderationsBudget: Determine your budget while considering the total cost of ownership, including maintenance and operation costs.

7. Additional FeaturesAccessories: Consider any additional accessories or attachments you might need, such as slings, hooks, or specialized hoists.

Customization Options: Some manufacturers offer customization to tailor the 10 ton gantry crane to your specific operational requirements.

Installation and Maintenance Tips for Your 10 Ton Gantry Crane:

Proper installation and regular maintenance of your 10 ton gantry crane are critical to ensuring safety and operational efficiency. By following these tips, you can enhance the longevity of your gantry crane, reduce downtime, and create a safer working environment. Prioritizing these aspects will ultimately lead to better performance and a higher return on investment.

Installation Tips

- Flat and Stable Ground: Ensure the installation area is level and can support the 10 ton gantry crane’s weight and load capacity.

- Clear Obstructions: Remove any obstacles in the area to allow for safe movement and operation.

- Installation Manual: Adhere to the manufacturer's instructions for assembly, ensuring all components are correctly fitted and secured.

- High-Grade Materials: Utilize quality bolts, fasteners, and components to enhance structural integrity.

- Vertical and Horizontal Levels: Use levels to ensure that the 10 ton gantry crane is aligned correctly, preventing unnecessary wear and safety hazards.

- Limit Switches: Install limit switches to prevent over-travel of the hoist and avoid collisions.

- Emergency Stops: Ensure emergency stop buttons are easily accessible.

Maintenance Tips

- Daily Checks: Inspect the 10 ton gantry crane before each use for any signs of wear, damage, or loose components.

- Monthly and Annual Inspections: Conduct thorough inspections to identify any issues that need attention.

- Routine Lubrication: Regularly lubricate moving parts, such as wheels and hoists, to reduce friction and wear.

- Follow Guidelines: Refer to the manufacturer’s recommendations for lubrication schedules and types of lubricants to use.

- Keep it Clean: Regularly clean the 10 ton gantry crane to remove dirt, dust, and debris that could interfere with its operation.

- Inspect for Corrosion: Check for signs of rust or corrosion, especially on metal components, and address them promptly.

- Check Wiring: Regularly inspect electrical connections and wiring for fraying or damage.

- Test Safety Features: Periodically test safety features like emergency stops and overload protection to ensure they function correctly.

Costs of 10 Ton Gantry Crane

1. Purchase PriceBase Model Costs: Prices for 10 ton gantry cranes can range from $2,000 to over $10,000 depending on features, materials, and brand.

Additional Features: Consider costs for additional features such as remote controls, enhanced safety systems, or specialized hoists.

2. Maintenance CostsLong-Term Maintenance: Electric 10 ton gantry crane may have higher maintenance costs due to electrical components, while manual cranes typically require less.

Replacement Parts: Factor in the availability and cost of replacement parts for both types of gantry crane.

3. Operating CostsPower Consumption: Electric gantry crane will incur ongoing electrical costs, while manual 10 ton gantry crane do not have this expense.

Comparing Electric vs. Manual 10 Ton Gantry Cranes: Which is Right for You?

When deciding between electric and manual 10 ton gantry cranes, it’s important to weigh the advantages and disadvantages of each option. Here’s a comparison to help you determine which type is right for your needs:

Electric Gantry Cranes

Advantages

- Ease of Use: Electric 10 ton gantry crane require minimal physical effort, making them user-friendly, especially for heavy loads.

- Increased Efficiency: Faster lifting and lowering speeds enhance productivity, allowing for quicker handling of materials.

- Consistent Performance: Electric hoists provide a steady lifting rate, reducing the risk of errors associated with manual operation.

- Advanced Features: Many electric models come with built-in safety features, such as overload protection, limit switches, and remote control options.

Disadvantages

- Higher Initial Cost: Generally more expensive than manual 10 ton gantry crane, both in terms of purchase price and installation.

- Dependence on Power Supply: Requires a reliable power source, which may not be available in all work environments.

- Maintenance Requirements: Electric components may require more maintenance and servicing over time.

Manual Gantry Cranes

Advantages

- Lower Initial Cost: Generally more affordable to purchase and install, making them a budget-friendly option.

- No Power Source Needed: Ideal for locations without electricity, as they can be operated anywhere.

- Simplicity and Reliability: Fewer moving parts means less chance of mechanical failure, leading to lower maintenance needs.

- Portability: Many manual gantry crane are designed to be lightweight and easily movable, making them suitable for various job sites.

Disadvantages

- Slower Operation: Lifting and lowering speeds are typically slower than electric gantry crane, which can affect productivity in high-demand environments.

- Less Precision: Manual operation may lead to inconsistencies in load handling, increasing the risk of accidents.

Applications of 10 Ton Gantry Crane in Various Industries:

- Manufacturing: 10 ton gantry crane used for moving heavy machinery, components, and materials during assembly processes.

- Construction: Ideal for lifting and transporting heavy construction materials, such as steel beams and concrete panels.

- Shipbuilding: 10 ton gantry crane used in shipyards to lift large components, sections, and equipment onto ships or between different work areas.

- Automotive: Helpful in automotive factories for lifting engines, chassis, and other heavy parts during assembly and maintenance.

- Warehousing and Distribution: Facilitates the loading and unloading of heavy items from trucks and containers, improving efficiency in storage facilities.

- Maintenance and Repair: Useful in maintenance shops for lifting heavy equipment, such as generators or large motors, for repair or replacement.

- Power Plants: Employed for handling heavy machinery and components during maintenance and operational tasks.

- Metallurgy: Used in foundries for moving heavy molds, castings, and machinery associated with metalworking.

- Aerospace: Assists in lifting and positioning large aircraft parts during assembly or maintenance.

- Recycling Facilities: Used for lifting and transporting heavy materials, such as scrap metal and industrial waste.