Ton Jib Crane & Price

500kg 3.5M H-3.5M BZ Jib Crane with Electric Chain Hoist for Sale to Saudi Arabia

Lifting Capacity: 0.5 ton

Span: 3.5 m

Lifting Height: 3.5 m

Working Class: A3

Note: We can design and manufacture the crane according your requirments and working conditions.

500kg 3.5M H-3.5M BZ Jib Crane for sale to Saudi Arabia:

- BZ 500kg jib crane

- Lifting capacity: 500KG

- Lifting height: 3.5M

- Span: 3.5M

- Voltage: 380V 60HZ 3P

- Lifting speed: 6.8 m/min

- Rotate radius: 5.5

- Rotate degree: 360

- Rotate speed: 0.5 m/min

- Electric Chain Hoist

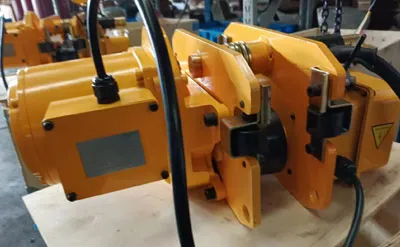

Production of 500kg 3.5M H-3.5M BZ Pillar Mounted Jib Crane for sale to Saudi Arabia:

500kg BZ Pillar Mounted Jib Crane: Key Features and Benefits for Efficient Material Handling:

A 500kg BZ pillar mounted jib crane is a specialized lifting system commonly used in industries where efficient material handling is essential, such as warehouses, workshops, and manufacturing facilities. Below are some of the key features and benefits of this type of 500kg jib crane:

Key Features of 500kg Jib Crane:

- Compact Design: BZ pillar mounted Jib Cranes typically have a space-saving design, making them ideal for environments with limited space.

- 360° Rotation: The 500kg jib crane arm can rotate 360 degrees, providing versatile maneuverability and flexibility when positioning loads.

- Durable Construction: These 500kg pillar mounted jib crane are often built with high-quality materials like steel to ensure a long lifespan and reliability under heavy use.

- Electric or Manual Operation: 500kg jib crane can come with electric or manual hoists, depending on the needs of the application.

- Easy Integration: 500kg pillar mounted jib crane are easy to integrate into existing workflows and can be adapted for use with other lifting systems or automation.

Benefits of 500kg Jib Cranefor Efficient Material Handling:

- Improved Productivity: With a 500kg lifting capacity, operators can quickly and efficiently move materials without requiring additional manpower or equipment, streamlining operations.

- Space-Saving: 500kg pillar mounted jib crane take up minimal space, which is particularly useful in confined areas. They provide overhead lifting without occupying valuable floor space.

- Increased Safety: 500kg jib crane help reduce manual lifting, lowering the risk of injuries from repetitive strain or accidents related to handling heavy items.

- Cost-Effective: Jib cranes are generally more affordable than larger overhead cranes, yet still provide the lifting capacity needed for smaller to medium-sized loads.

- Easy Maintenance: With fewer moving parts compared to other heavy machinery, BZ 500kg pillar mounted jib crane are easy to maintain, reducing downtime and maintenance costs.

How to Choose the Right 500kg BZ Pillar Mounted Jib Crane for Your Workspace:

Choosing the right 500kg pillar mounted jib crane for your workspace involves assessing several factors to ensure it fits your operational needs and environment. Here’s a guide to help you make an informed decision:

- Weight of Loads: Ensure the jib crane has a 500kg load capacity and can handle the heaviest items you need to lift regularly.

- Frequency of Use: Consider how often the 500kg jib crane will be in use. If it's going to be a frequently used tool, opt for a model with high durability and long-lasting components.

- Work Area Size: 500kg jib crane are ideal for tight spaces, but you still need to ensure that the jib crane’s dimensions (arm length, height, etc.) fit within your workspace.

- 360° Rotation: If you need to move materials in multiple directions, choose a model with full 360° rotation. This adds versatility to your operations by allowing the 500kg jib crane to handle loads from various angles.

- Electric vs. Manual Hoist: Decide between a manual hoist or an electric hoist based on the weight and frequency of your lifts.

- Build Quality: Ensure that the 500kg jib crane is made of high-quality, durable materials like steel or heavy-duty alloys. A well-constructed crane will stand up to constant use and last longer.

- Corrosion Resistance: If your workspace involves harsh environments, such as outdoors or areas with high humidity, consider choosing a jib crane with a protective coating to prevent rust and corrosion.

Packing of 500kg 3.5M H-3.5M BZ Pillar Mounted Jib Crane for sale to Saudi Arabia:

Installation Guide for a 500kg Pillar Mounted Jib Crane:

1. Foundation Installation:

- Mark Foundation Holes: Depending on your crane model, mark where the mounting base will be attached to the ground. These holes should be accurately positioned, and you might need to drill into concrete or another surface.

- Drill Holes: If you are mounting to a concrete foundation, drill the required holes using a suitable drill bit.

- Anchor Bolts: Install anchor bolts into the holes to secure the crane base (if required).

- Base Plate: Place the base plate of the crane in position on the foundation and use washers and nuts to secure it tightly.

2. Assemble the Pillar:

- Secure the Pillar: Tighten the anchor bolts or fasteners to secure the pillar firmly in place. Use a torque wrench to ensure the correct tension is applied (refer to the manufacturer’s torque specifications).

3. Install the Jib Arm:

- Attach the Jib Arm: Secure the jib arm to the pillar using bolts or fasteners, ensuring that it is properly aligned. Double-check the alignment for correct angle and reach.

- Check the Rotation: Test the arm’s ability to rotate smoothly around the pillar. If the crane is equipped with a slewing mechanism (e.g., gear or bearings), ensure that it is properly lubricated and free of obstructions.

4. Install the Hoist

- Mount the Hoist: If your jib crane includes a hoist, install it on the jib arm according to the manufacturer's instructions.

5. Wiring and Power Setup :

- If your crane is powered (electric hoist or motorized rotation), you will need to wire the electrical components.

500kg Pillar Mounted Jib Crane Maintenance Tips for Longevity:

1. Regular Inspections

- Check for Wear and Tear: Regularly inspect the 500kg jib crane’s key components, including the pillar, jib arm, hoist, trolley, and slewing mechanism, for signs of wear or damage.

- Look for Cracks: Check for any cracks or deformations in the metal components, especially around stress points.

- Lubrication Points: Make sure the lubrication points are well-maintained and that grease or oil is applied as required by the manufacturer.

2. Check Fasteners and Bolts

- Tighten Bolts: Regularly check all bolts, nuts, and fasteners to ensure they are tightened to the correct torque.

- Use a Torque Wrench: Always use a torque wrench to tighten bolts to the recommended specifications. This ensures that you don't overtighten or under-tighten.

3. Inspect the Hoist and Trolley

- Trolley Movement: Ensure the trolley moves smoothly along the jib arm. If the trolley is not moving freely, clean or lubricate the track and wheels. Inspect for any blockages or obstructions.

- Test the Hoist: Periodically test the hoist for proper lifting performance. Verify that the motor (if electric) runs smoothly and that the lifting mechanism is functioning without hesitation.

4. Slewing Mechanism and Rotation

- Inspect Bearings and Gears: The slewing mechanism (if your crane has one) should be checked for smooth operation. Inspect the bearings, gears, or chain system for wear, and lubricate regularly to reduce friction and extend lifespan.

- Ensure Rotation is Smooth: The jib arm should rotate smoothly around the pillar. If you notice any resistance, inspect the slewing ring or rotation mechanism for damage.

Application of 500kg Pillar mounted jib crane in Saudi Arabia

Saudi Arabia's economic diversification efforts are focused on reducing reliance on oil by investing in infrastructure, manufacturing, tourism, and renewable energy. The 500kg pillar mounted jib crane offers a solution that aligns with the country’s goals to modernize its industrial landscape.- Construction and Infrastructure Projects: With the rapid growth of infrastructure projects across Saudi Arabia, such as the development of new cities like Neom, and numerous residential, commercial, and industrial developments, the demand for efficient material handling equipment is higher than ever. The 500kg pillar mounted jib crane is an ideal solution for lifting and transporting heavy materials in tight spaces, such as construction sites with limited room for large cranes.

- Manufacturing and Factory Settings: Saudi Arabia’s manufacturing industry Factories focused on sectors like automotive, steel, and petrochemicals can greatly benefit from 500kg pillar mounted jib crane . These jib cranes can improve efficiency on assembly lines by facilitating quick and safe lifting of heavy components, reducing downtime, and boosting production rates.

- Logistics and Warehousing: With the growth of e-commerce and the logistics sector in Saudi Arabia, 500kr pillar mounted jib cranes are playing a critical role in warehousing operations. In storage facilities, they are used to lift and move packages, containers, or heavy goods from one location to another.

- Oil and Gas Industry: Saudi Arabia is a global leader in the oil and gas industry. 500kg pillar mounted jib crane are valuable in smaller operations, such as maintenance workshops, where they can be used to lift heavy tools and parts.

Previous:Different Types of Jib Crane for Sale

Next: Sorry no more