10 Ton Gantry Crane

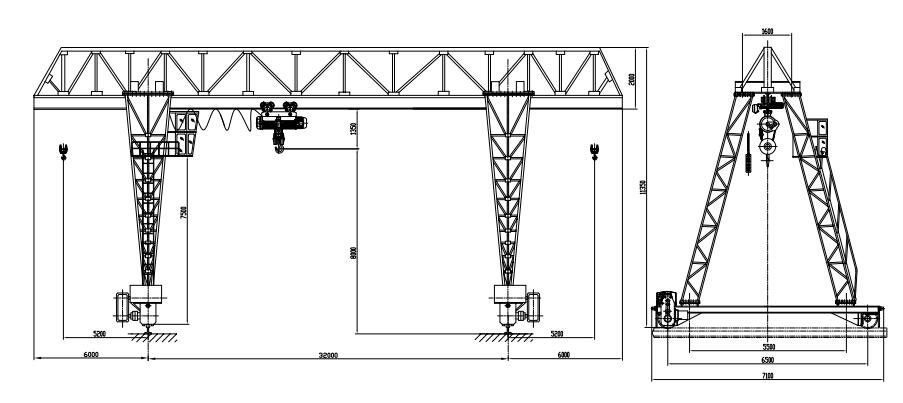

The Specifications and Configuration of 10 Ton Single Girder Gantry Crane to Uzbekistan

Lifting Capacity: 10 ton

Span: 32 m

Lifting Height: 8 m

Working Class: A4

Note: We can design and manufacture the crane according your requirments and working conditions.

The steel industry is a sector that requires a large number of single girder 10 ton gantry crane specifications. These 10 ton gantry crane play a crucial role in helping manufacturers transfer raw materials to the production line, as well as moving finished products from the production line to storage areas or transportation vehicles. 10 ton gantry crane can also assist with the installation and maintenance of heavy machinery and equipment. Therefore, having efficient and reliable crane equipment is an indispensable part of the steel production process and a key factor in ensuring production capacity and quality.

Our Uzbekistan client ask we to provide a single girder gantry crane with the following specifications: width – 32 meters, load capacity - 10 tons, console – 6 meters on each side, lifting height – 8 meters, average speed, and cabin control.

Our client is in the Uzbekistan steel industry in. With the increasing demand for steel products in domestic and foreign markets, Uzbekistan's steel production enterprises will have more opportunities to expand their market share. In addition, the Uzbekistan government has been committed to promoting industrial modernization and technological innovation, which will provide more support and guarantee for the development of the steel industry. Moreover, Uzbekistan's advantageous geographical location and convenient transportation links with the rest of the world create good conditions for the export of the steel industry.

10 ton single girder gantry crane specifications and Configuration:

| Item | Single Girder Gantry Crane | ||

| Lifting capacity | t | 10 | |

| Lifting height | m | 8 | |

| Span | 32 | ||

| Console | Left | 6 | |

| Right | 6 | ||

| Speed | Cross traveling speed | m/min | 20 |

| Crane traveling speed | 20 | ||

| Lifting speed | 7.0 | ||

| Working class | / | A4 | |

| Power supply | V/Hz/P | 380V/50HZ/3P | |

| Crane traveling power | KW | 4.0*2 | |

| Trolley traveling power | 0.8*2 | ||

| Lifting power | 13 | ||

| Total power 36.2 | 36.2 | ||

| Max. wheel load | KN | 172 | |

| Total design weight | t | 30.6 | |

| Ambient temperature | / | -20℃ ~ +40℃ | |

Single girder 10 ton gantry crane components:

| Main structure |  |

Main girder | Q235B carbon structural steel plates welded into box structure, easy to maintain. Three-layer painting |

|

Support legs | Q235B carbon structural steel material, box structure design, high safety and rigidity, easy to maintain. Three-layer painting | |

|

End carriages | Q235B carbon structural steel with quality wheels and powerful motor Three-layer painting | |

| Lifting mechanism |  |

Lifting hoist | Wire rope hoist with reducer, drum, motors and electric trolley, Protection class IP54 Class F insulation |

|

Drum | Self-produced. Drums made of high-quality seamless steel processed by CNC machine | |

|

Wire rope | Rope structure 6×37SW, fiber core. | |

|

Rope guide | installed on the winding drum to guide the wire rope, prevent constant winding of steel wire and prolong the life of the drum, nodular cast iron | |

|

Hook | Drop Forged, plain ‘C’ type, swiveling on Thrust Bearing, belt buckle and wire ropes sheath | |

|

Lifting & Cross travelling motor | Special designed squirrel-cage motor for the electric hoist, soft start system Maintenance free. Insulation grade F. Protection class IP54. Electromagnetic disc type brake system | |

|

Hoist reducer | Totally enclosed type with Splash Lubrication, gear box shell pressure casting | |

| Travelling mechanism |  |

Hoist trolley | Alloy gear and wheels, 125% testing load of the rated capacity. |

|

Reducer | For the crane travelling reducer, totally enclosed type with Grease Lubrication, gear box shell pressure casting | |

|

Crane wheels | Installed on the crane end carriages as drive wheels, high carbon steel material vacuum casting by our group, Intermedium quenching by top technique machinery anti-rust painting. | |

| Electric parts |  |

Electric cabinet | CHINT brand, Chinese best brand, Protection class IP54 |

|

Festoon cable | Supply power for the trolley and hoist, C- type cable track, safe and reliable | |

|

Cabin control | Wide field of view, can see the whole site when lifting things, reduce accident rate. It is easy to operate, safe and efficient. | |

| Protection system |  |

Lifting limit switch | For lifting protection, prevent the hook from knocking the hoist |

|

Travelling limiter switch | For cross travel & long travel, Protect the crane before it crashes the object | |

|

Overload limit | For lifting protection, monitor the crane situation | |

|

Buffer | Used for anti-collision |

Functions of single girder 10 ton gantry crane specifications in steel production:

- Raw material transportation: 10 ton gantry crane can transfer raw materials from transportation vehicles or storage areas to the production line, ensuring timely and efficient supply of raw materials.

- Charging: 10 ton gantry crane can transfer charging materials to blast furnaces or steelmaking furnaces, ensuring smooth and stable production processes.

- Molten steel transportation: cranes can transfer molten steel from steelmaking furnaces or casting equipment and transport it to the next processing step.

- Product transportation: cranes can transfer finished products from the production line to storage areas or transportation vehicles, ensuring timely delivery of products.

- Equipment installation and maintenance: cranes can assist in the installation and maintenance of heavy machinery and equipment, improving production efficiency and equipment utilization.

10 ton gantry crane play a crucial role in steel production, and are indispensable for ensuring production capacity, improving production efficiency, and maintaining quality standards.

You can choose our single girder 10 ton gantry crane:

Thank you very much for your interest in our company. We are glad to provide you with the supply of 10 ton gantry crane. Our company is a professional enterprise engaged in the production and sales of cranes, with many years of industry experience and rich technical strength. Our 10 ton gantry crane adopt advanced design and manufacturing technology, with advantages such as reasonable structure, smooth operation, and safety and reliability. At the same time, we can also provide customized solutions according to customers' specific needs to meet different requirements. If you are interested in our products, please feel free to contact us at any time. We will be happy to provide you with the best service and products.

Gantry crane certificates: