10 Ton Gantry Crane

10 Ton H-15m Double Girder Gantry Crane with Electric Wire Rope Hoist for sale to Thailand

Lifting Capacity: 10 ton

Span: m

Lifting Height: 15 m

Working Class: M6

Note: We can design and manufacture the crane according your requirments and working conditions.

10 Ton H-15m Double Girder Gantry Crane with Electric Wire Rope Hoist for sale to Thailand:

Lifting capacity: 10 TonLifting height: 15m

Lifting speed: 0.74/4 m/min

Traveling speed: 2-20 m/min

Working Class: M6

10 Ton Gantry Crane accessories:

Maximize Your Efficiency: The Benefits of a 10 Ton Gantry Crane for Your Operations

- Versatility: 10 ton gantry crane can be used in diverse environments—warehouses, shipping yards, manufacturing plants, and construction sites. Their adaptability makes them valuable for various tasks, from moving materials to assembling large components.

- Space Optimization: 10 ton gantry crane can be moved along tracks or within designated areas. This mobility allows you to optimize workspace by repositioning the crane based on operational needs.

- Enhanced Safety: Modern 10 ton gantry crane are equipped with safety features such as overload protection, emergency stop functions, and advanced control systems.

- Improved Workflow: By streamlining the movement of heavy materials, a 10 ton gantry crane can significantly enhance workflow efficiency.

- Customizable Options: Many manufacturers offer customizable gantry cranes tailored to specific operational needs. Options like adjustable heights, wheel types, and track configurations ensure you get the right fit for your facility.

- Enhanced Mobility: The design of gantry cranes allows for easy movement within a facility. This flexibility enables quick reconfiguration of workflows, making it simpler to adapt to changing operational demands.

- Durability and Reliability: Constructed from robust materials, 10 ton gantry crane are built to withstand the rigors of industrial environments. Their reliability minimizes downtime due to equipment failure, ensuring continuous operation.

Choosing the Right 10 Ton Gantry Crane: A Comprehensive Guide for Buyers

Selecting the right 10 ton gantry crane is crucial for enhancing operational efficiency and safety in various industrial applications. Here’s a comprehensive guide to help buyers make informed decisions:

1. Understand the Environment

Indoor vs. Outdoor Use: Determine whether the gantry crane will be used indoors, outdoors, or both. Outdoor gantry cranes may need to withstand environmental elements, so corrosion-resistant materials are essential.

2. Choose the Right Material

Construction Material: Most 10 ton gantry cranes are made from steel or aluminum. Steel is robust and durable, while aluminum is lightweight and easier to move. Consider your needs based on strength and mobility.

3. Mobility Features

Fixed vs. Mobile: Decide if you need a fixed gantry crane or a mobile one with wheels. Mobile gantry cranes offer flexibility to relocate based on operational needs.

Wheel Design: Look for heavy-duty wheels suitable for the surfaces they will traverse.

4. Safety Features

Overload Protection: Ensure the 10 ton gantry crane has mechanisms to prevent lifting loads beyond its rated capacity.

Emergency Stops: Check for easily accessible emergency stop buttons for quick response in case of emergencies.

5. Control Mechanisms

Operational Controls: Look for user-friendly control systems, including manual and remote options, to facilitate ease of operation.

Precision Control: Features like variable speed controls enhance precision during lifting and lowering.

6. Consider Customization Options

Modularity: Some 10 ton gantry cranes offer modular designs that allow for future adjustments or expansions as your needs change.

Attachments: Explore available attachments, such as lifting slings or spreader bars, that can enhance functionality.

10 Ton Gantry Crane Production:

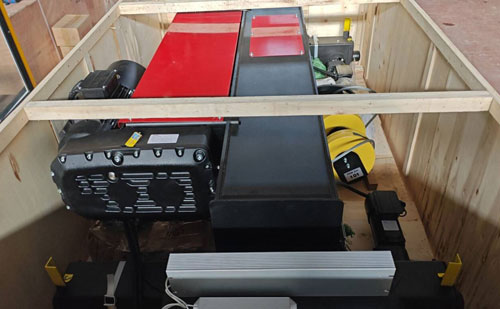

Packaging and Transportation of 10 Ton Gantry Crane:

Investing in a 10 Ton Gantry Crane: Cost and ROI

Investing in a 10 ton gantry crane can be a significant decision for any business involved in heavy lifting or material handling.

Costs

- Initial Purchase Price: A new 10 ton gantry crane typically ranges from $4,000 to $50,000, depending on the manufacturer, features, and customization options.

- Annual maintenance: Regular inspections and servicing are essential for safety and longevity.

- Operating Costs: Electricity (if powered) and any labor costs associated with operating the gantry crane.

ROI Considerations

- Increased Efficiency: A 10 ton gantry crane can significantly speed up lifting operations, reducing labor time and increasing productivity.

- Labor Savings: By automating lifting tasks, you can reduce the number of workers needed for manual lifting, resulting in cost savings.

- Improved Safety: Investing in a 10 ton gantry crane reduces the risk of injury associated with manual lifting, potentially lowering workers' compensation costs.

- Versatility: These 10 ton gantry crane can be used for various applications (manufacturing, warehousing, construction), providing flexibility for different projects.

Investing in a 10 ton gantry crane can yield significant benefits, including improved efficiency, safety, and cost savings. Carefully evaluate the initial costs against potential ROI based on your specific operational needs and projected workload. Analyzing these factors will help you make a more informed decision on your investment.

Installation of 10 ton gantry crane in Thailand:

Installation operation video of 10 Ton H-15m Double Girder Gantry Crane with Electric Wire Rope Hoist for sale to Thailand:

Here is a series of installation operation videos about 10 Ton H-15m Double Girder Gantry Crane with Electric Wire Rope Hoist for sale to Thailand, please watch?

Application of 10 Ton Gantry Crane in Thailand:

In Thailand's growing economy, a 10 ton gantry crane finds valuable applications across several sectors:

- Manufacturing: With a robust manufacturing sector in Thailand, 10 ton gantry crane are essential for lifting heavy machinery, parts, and materials in factories, enhancing production efficiency.

- Construction: In the booming construction industry, 10 ton gantry crane facilitate the movement of steel beams, precast concrete, and other heavy materials on-site, ensuring timely project completion.

- Logistics and Warehousing: As Thailand strengthens its logistics infrastructure, 10 ton gantry crane aid in loading and unloading heavy goods in warehouses, improving operational workflows.

- Shipbuilding and Repair: In Thailand coastal areas, 10 ton gantry crane are vital for shipbuilding and maintenance, allowing for the safe lifting and positioning of heavy components.

- Agriculture and Food Processing: 10 ton gantry crane used in agricultural processing facilities for handling heavy equipment and large batches of products, supporting Thailand’s significant agricultural sector.

- Energy Sector: In renewable energy projects, such as solar and wind farms, 10 ton gantry crane assist in installing and maintaining large components, contributing to Thailand's energy goals.

Investing in 10 ton gantry cranes can boost productivity, reduce labor costs, and enhance safety, aligning with Thailand's economic development objectives. By improving operational efficiency across these sectors, businesses can better position themselves in an increasingly competitive market.

Previous:The Specifications and Configuration of 10 Ton Single Girder Gantry Crane to Uzbekistan

Next: Sorry no more