5 Ton Overhead Crane

5 Ton 6.3M H-3.85M Single Girder Overhead Crane with European Electric Wire Rope Hoist for Sale to Lebanon

Lifting Capacity: 5 ton

Span: 6.3 m

Lifting Height: 3.85 m

Working Class: M5

Note: We can design and manufacture the crane according your requirments and working conditions.

5 Ton Single Girder Overhead Crane with European Electric Wire Rope Hoist for Sale to Lebanon:

- Lifting capacity:5 Ton

- Lifting height: 3.85M

- Span: 6.3M

- Working Class: M5

- Liftinf speed: 0.8/5 m/min

- Traveling speed: 2-20 m/min

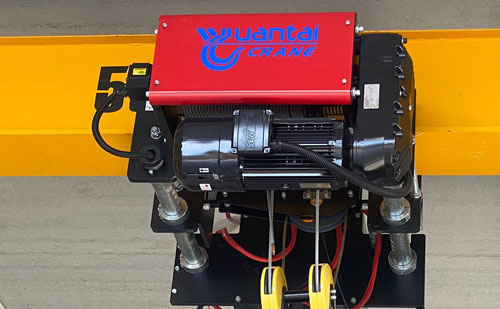

Production of 5 Ton Single Girder Overhead Crane:

Top 5 Features to Look for in a 5 Ton Single Girder Overhead Crane:

When selecting a 5 ton single girder overhead crane, consider the following top features:

- Load Capacity and Stability: Ensure the overhead crane is designed to safely handle the 5 ton capacity, with features like reinforced structures and a solid base to maintain stability during operation.

- Span Length: Evaluate the span length based on your facility's layout. The 5 ton overhead crane should have a suitable span that allows efficient coverage of the work area without compromising safety or performance.

- Control System: Look for an intuitive control system, such as remote control or pendant controls, that enhances ease of use and operator safety. Features like variable speed control can improve precision during lifting and positioning.

- Safety Features: Safety is paramount. Choose a 5 ton overhead crane with built-in safety features such as overload protection, limit switches, and emergency stop buttons. Additional safety options like anti-collision systems may also be beneficial.

- Durability and Maintenance: Select a 5 ton overhead crane made from high-quality materials that can withstand the demands of your environment. Consider models that require minimal maintenance, and check for accessible parts for easy servicing.

From Installation to Maintenance: A Comprehensive Guide to Your 5 Ton Crane

Here's a comprehensive guide covering the installation and maintenance of your 5 ton overhead crane:Installation of 5 ton overhead crane:

- Assess the Space: Ensure the area can accommodate the 5 ton overhead crane's span and height.

- Structural Support: Confirm that the building structure can support the 5 ton overhead crane's weight and load capacity.

- Assembly: Follow the manufacturer's instructions for assembling the 5 ton overhead crane components (girder, hoist, trolley).

- Positioning: Securely mount the 5 ton overhead crane on the runway beams. Ensure proper alignment for smooth operation.

- Electrical Setup: Connect the 5 ton overhead crane to the power supply, ensuring all electrical work meets local codes and safety standards.

- Testing: Perform initial tests to check functionality, including load tests and safety features.

Maintenance of 5 ton overhead crane:

- Conduct daily inspections as mentioned in the operation section.

- Inspect electrical systems, check for wear on chains/ropes, and clean any accumulated debris.

- Examine structural integrity, alignment, and condition of bearings and wheels.

- Engage a qualified technician to perform a thorough examination of all components, including brakes, hoists, and safety devices.

- Replace any components that show significant wear or damage.

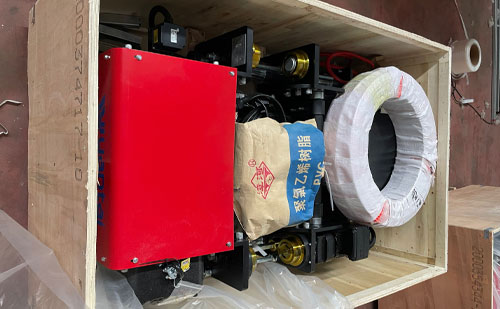

Packaging of 5 Ton Overhead Crane:

Operation of 5 ton overhead crane:

- Operator Training: Ensure all operators are trained on the overhead crane's controls, safety protocols, and emergency procedures.

- Pre-Operation Inspection: Check for any visible damage, wear on ropes/chains, and functionality of controls and safety devices.

- Lubrication: Ensure moving parts are properly lubricated according to the manufacturer’s specifications.

- Load Management: Always operate within the 5 ton overhead crane's rated capacity. Use appropriate rigging techniques.

- Clear Communication: Establish clear signals between operators and ground personnel.

- Environment Awareness: Be mindful of surroundings, potential obstacles, and overhead hazards.

Shipping of 5 Ton Overhead Crane:

The application of 5 ton single girder overhead crane in Lebanon:

The application of 5 ton single girder overhead cranes is of great importance in the context of the Lebanese economy. Here are some key points:- Improving productivity: with the recovery of the industrial and construction sectors in Lebanon, 5 ton single girder overhead cranes can significantly improve the efficiency of material handling, reduce labor costs and time, and increase overall productivity.

- Adapt to small enterprises: Many Lebanese small and medium-sized enterprises are facing financial pressures. 5 ton single girder overhead cranes are suitable for these enterprises due to their relatively low investment costs and maintenance expenses.

- Promoting infrastructure construction: In Lebanon, infrastructure construction is an important part of economic recovery. 5 ton overhead crane can efficiently move heavy loads at construction sites, warehouses and manufacturing plants.

- Flexibility and Versatility: 5 tons single girder overhead travelling crane is designed to be flexible and can be used in different working environments such as factories, ports and construction sites in Lebanon.

- Safety Enhancement: Modern 5 ton overhead crane are equipped with a wide range of safety devices that can reduce the risk of accidents, which is especially important during economic recovery in Lebanon, helping to protect worker safety and reduce potential economic losses.

In the current economic environment of Lebanon, the application of 5-ton single girder overhead travelling crane can not only improve the operational efficiency of enterprises, but also promote the overall economic development.