Projects

5 Ton Overhead Crane with Electric Hoist Specification

Lifting Capacity: 5-32 ton

Span: 7.5-31.5 m

Lifting Height: 3-30 m

Working Class: A3, A4

Note: We can design and manufacture the crane according your requirments and working conditions.

5 ton overhead crane specificationis a high-quality lifting equipment that is designed to meet the needs of modern industrial settings. With a reasonable design and small size, this crane is perfect for workshops with limited space and low headroom. 5 ton overhead crane specification with electric hoist is equipped with advanced technology that ensures energy-saving and efficient operation, making it a reliable choice for lifting heavy materials and products.

Overhead crane with electric hoist is also designed to maximize lifting height, allowing you to make the most of your workshop's space and increase productivity. Overhead crane with electric hoist has a light dead weight and low wheel loading, which makes it easy to move around and reduces the risk of damage to your floors.

Overhead crane with electric hoist features frequency control of motor speed, which ensures stable traveling and makes it easy to control the lifting process. It is matched with electric hoists of CD1 model, MD1 model, and other models, which ensures smooth and efficient operation.

Overhead crane with electric hoist is widely used in processing workshops, metallurgical assisting warehouses, storage yards, and power stations. It is a versatile and reliable lifting equipment that can help you increase productivity and improve your workflow.

5 Ton Overhead Crane Specification:

| Lifting Capacity | t | 5 | ||||||

| span(S) | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Lifting Speed(slow) | m/min | 8(0.8) | ||||||

| Trolley Speed | m/min | 20 | ||||||

| Crane speed | m/min | 20(ground control);45(cabin control) | ||||||

| Lifting Motor | kw | 7.5/0.8 | ||||||

| Trolley Motor | kw | 0.8×2 | ||||||

| Body weight(ground control) | kg | 5230 | 6400 | 7450 | 8600 | 10560 | 12350 | 14850 |

| Body weight(room control) | kg | 5730 | 7100 | 8150 | 9300 | 11260 | 13100 | 15560 |

| Max wheel load | KN | 39 | 43 | 48 | 53 | 59 | 62 | 71 |

| Recommended Rail |

|

P38 | ||||||

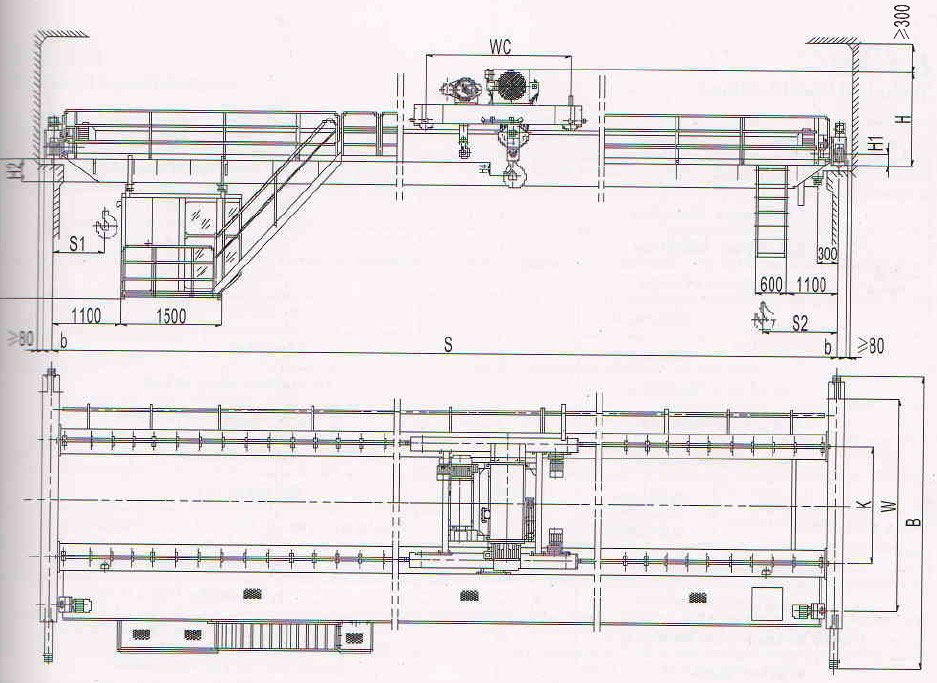

| Main dimension | mm | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Wheel tread to hoist top | H | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1550 |

| Wheel tread to main girder bottom | H2 | 165 | 165 | 165 | 265 | 365 | 465 | 370 |

| Wheel tread to hook centre | H4 | 385 | 385 | 385 | 385 | 385 | 385 | 540 |

| End girder wheels' distance | W | 3200~3900 | 3200~3600 | 3800 | ||||

| End girder lenth | B | 2700~3100 | 3700~4200 | 5300 | ||||

| Trolley track gauge | K | 1400~1800 | ||||||

| Hook left limitation | S1 | 1200 | ||||||

| Hook right limitation | S2 | 1200 | ||||||

5 ton overhead crane with electric hoist specification structure and feature:

5 ton overhead crane with electric hoist is a reliable and efficient lifting equipment that is designed to meet the needs of modern industrial settings. It consists of a bridge frame, trolley, crane traveling mechanism, and electrical equipment.

The bridge frame is made up of a double main girder, end girder. The main girder is welded in a box shape and made of steel material model Q235B or Q345B. The end girder is welded by rectangle tube or quality steel plate and connected to the main girder by strong bolts.

The trolley has a compact structure, small size, and light weight. It is equipped with a motor, reducer, trolley frame, and hoist. The lifting mechanism is the same as the hoist's, and the traveling rail can be P-shape rail or square-steel rail.

The crane traveling mechanism is designed for safe and stable operation. It uses soft start and small current when ground control, which reduces axial sway. The motor has few and adapts to frequent starting, making it energy-saving. The cabin control uses ZDR series cone winding rotor, three-phase asynchronous motor, or electromagnetic brake motor. The crane wheel, trolley wheel, and brake wheel use mid-frequency induction hardening and industrial frequency quenching processing to ensure high mechanical strength.

The electric parts of the 5 ton overhead crane with electric hoist are designed for safety and convenience. The safe touch line conductive rate is high, and the low-pressure set electric taxi speed is high. The wire ropes in the electrical box are in order and convenient to repair. Trolley moving's power is supplied by flat cable, which ensures smooth sliding and a beautiful outlook.

5 ton overhead crane specification structure drawing:

5 ton overhead crane with electric hoist is equipped with various protection devices:

5 ton overhead crane with electric hoist is equipped with various protection devices to ensure safe and efficient operation in industrial settings. These devices help to prevent accidents, protect the equipment, and ensure a safe working environment for everyone involved.

- For outdoor cranes, lifting mechanisms, electrical control boxes, and rainproof devices are installed to protect the equipment from weather damage. This ensures that the 5 ton overhead crane with electric hoist can operate smoothly even in harsh weather conditions.

- The trolley trip spacing device is also installed to prevent accidental collisions between the trolley and the end of the track. This helps to protect the equipment and prevent damage to the products being lifted.

- Anti-collision devices are also installed to prevent collisions between the crane and other objects in the working area. This helps to prevent accidents and protect both the equipment and the workers.

- Audible and visual alarm device is installed to alert workers of any potential safety hazards. This ensures that workers are aware of any potential dangers and can take appropriate action to prevent accidents.

what is 5 ton overhead crane power requirements:

The power requirements for a 5-ton overhead crane depend on various factors, including the type of crane, its usage, and the specific features it has. Generally, the power requirements for an overhead crane are determined by the following factors:

1. Crane Type: The type of crane you're using, whether it's a traditional electric overhead crane, a gantry crane, or a bridge crane, will impact the power requirements. Different types of cranes may have different motor configurations.

2. Duty Cycle: The duty cycle refers to how frequently and for how long the crane is in operation. Cranes used in continuous or heavy-duty applications will have higher power requirements compared to those used intermittently.

3. Hoist and Trolley Speed: The speed at which the hoist and trolley need to move the load can affect power requirements. Faster speeds generally require more power.

4. Crane Configuration: The specific configuration of the crane, including the number and type of motors and the voltage, will impact power requirements.

5. Power Supply: The voltage and current supply available in your facility will determine the power requirements. Cranes are typically powered by electricity, and you need to ensure that your facility can provide the required voltage and current.

6. Efficiency: The efficiency of the crane's motors and other components will impact the power consumption. More efficient motors will consume less power.

To calculate the exact power requirements for a 5-ton overhead crane, you'll need to consult the crane manufacturer or a qualified engineer who can consider all these factors and determine the specific power requirements based on your crane's specifications and intended usage. They can also help you select the appropriate power supply and electrical infrastructure to support the crane's operation.

Dongqi Crane, since 1984, is a professional 5 ton overhead crane manufacturer.

Dongqi Crane can provide a series of crane services: including but not limited to Crane project design - Crane Installation - Lifetime Maintenance - Crane operator Training - 24/7 Technical support - Crane Modernization - Crane Parts supplying , etc.

Please do not hesitate to leave a message below and tell us who you are and what you are interested and the information you want will be at your hand at once.