Projects

10 Ton Overhead Crane Specifications and Drawing-Single Girder

Lifting Capacity: 10 ton

Span: 3-35 m

Lifting Height: 3-30 m

Working Class: A3, A4

Note: We can design and manufacture the crane according your requirments and working conditions.

10 ton overhead crane specifications is a common, efficient, reliable, safe, and easy-to-maintain lifting device that is suitable for many different applications, such as factories, workshops, and warehouses. 10 ton overhead crane specifications is designed for medium to heavy Lifting applications and consists of a bridge, lifting mechanism, electrical equipment, and control system. The structure of the 10 ton bridge crane is compact and occupies a small area, making it highly efficient in limited spaces. The crane is equipped with Multiple safety protection measures, such as limit switches, overload protection, power failure protection, etc., to ensure the safety of operators and equipment.

10 ton overhead crane specifications-single girder:

| Capacity | t | 10 |

| Span | m | 3~35 |

| Lifting Height | m | 3-30 |

| Lifting Speed | m/min | 0.8/5,dual speed |

| Working Class | A3-A4 | |

| Trolley Travelling Speed | m/min | 3~30,VFD control |

| Crane Travelling Speed | m/min | 3~30,VFD control |

| Control Method | Ground or Cab Control | |

| Power Supply | 380V 50HZ 3PHASE or Customized | |

| Temperature | ℃ | -20~60 |

| Protection Grade | IP54~65 |

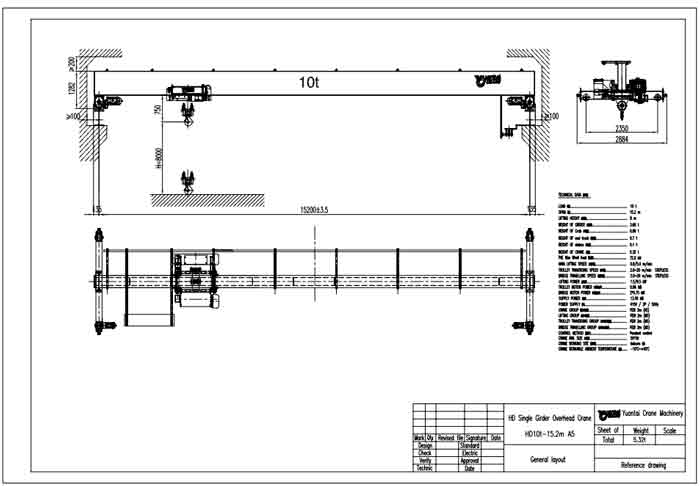

10 ton overhead crane specifications design drawing-single girder:

Installation Techniques for 10 Ton Overhead Crane:

Installing a 10 ton eot crane requires careful site inspection, following the instruction manual for installation, conducting comprehensive inspection and testing, and providing training to the operators. These techniques ensure that the crane can work properly and guarantee the safety of the operators and equipment.

- Preparation before installation: Before installing the crane, it is necessary to check whether the installation site meets the requirements, including ground flatness, power connection, etc. Ensure that there are no obstacles that will hinder the installation of the crane.

- Installation sequence: Follow the steps in the instruction manual for installation. First, install the bridge, then install the lifting machinery and electrical equipment. During the installation process, it is necessary to ensure that each component is in the correct position and direction.

- Inspection: After installation is complete, a comprehensive inspection must be conducted, including electrical systems, mechanical systems, limit switches, etc. Ensure that all systems are working properly.

- Testing: After the inspection is complete, test the crane. First, perform a no-load test run, then perform a load test run. During the test run, it is necessary to check whether the crane operates smoothly and whether there is any abnormal noise.

- Training: After the installation and testing of the crane are completed, training must be provided to the operators to ensure that they understand how to operate and maintain the crane correctly.

Specifications of 10 ton overhead crane price:

The 10 ton overhead crane price varies depending on the brand, model, configuration, and supplier, generally ranging from $10,000 to $50,000. The specific price also needs to be determined based on the customer's requirements and customization needs.

In addition, the price of a 10 ton bridge crane is also affected by factors such as market supply and demand, material costs, labor costs, and transportation costs. Some well-known brands with good quality and after-sales service may have higher prices.

Furthermore, different countries and regions have different standards and certification requirements for bridge cranes, which also affects prices. Therefore, when purchasing a 10 ton eot crane, it is necessary to compare and consider multiple aspects, choose a product with good cost performance, and pay attention to reasonable budget arrangements.

10 ton overhead cranes can improve safety in the workplace in several ways:

- Increased efficiency: A 10 ton overhead crane can lift heavy objects more easily and quickly than manual labor. This reduces the need for workers to engage in strenuous physical labor, which can lead to injuries.

- Improved accuracy: Eot cranes can be controlled with precision, allowing for more accurate and safe placement of heavy loads.

- Reduced risk of damage: With an overhead crane, there is less risk of damage to the load being lifted, as well as to the surrounding equipment and structures.

- Improved ergonomics: Overhead cranes eliminate the need for workers to bend, twist, or reach awkwardly, reducing the risk of musculoskeletal injuries.

- Enhanced safety features: Modern 10 ton eot cranes are equipped with advanced safety features, such as overload protection, anti-collision systems, and emergency stop buttons. These features help prevent accidents and injuries in the workplace.

Maximize Your Workspace with a 10 Ton Overhead Crane:

- Vertical lifting: Overhead cranes lift loads vertically, allowing you to use the height of your facility more efficiently. This frees up valuable floor space for other activities.

- Precision placement: Overhead cranes can be controlled with precision, allowing for accurate and safe placement of heavy loads in tight spaces.

- Improved workflow: Overhead cranes can move heavy loads quickly and easily, reducing the need for manual labor and improving workflow efficiency.

- Customizable: Overhead cranes can be customized to meet specific lifting requirements, including height, span, and lifting capacity. This allows you to tailor the crane to your workspace and lifting needs.

- Reduced clutter: Overhead cranes do not take up valuable floor space like other types of lifting equipment, reducing clutter in the workspace and improving safety.

Which working class of 10 ton overhead crane is suitable for your application:

The working class of a 10 ton overhead crane is usually between A3 and A6, where A3 to A4 class are suitable for light-duty work, while A5 to A6 class are suitable for heavy-duty work. If your application requires lifting lighter items and is not used frequently, then an A3 or A4 class crane may be a better choice. If you need to handle heavier items or use the crane frequently, then you will need to choose a higher class crane. Additionally, if your application environment is harsh, such as high temperature, humidity, or corrosion, you may need to choose a higher class crane to ensure its durability and reliability. It is recommended to consult with professional crane manufacturers or salespeople for more accurate and detailed advice.

10 ton overhead crane power requirement:

The 10 ton overhead crane power requirements depend on the voltage and frequency of the power supply. Generally, 10 ton overhead crane may require a power supply of 380 V voltage and 50 Hz frequency. This type of power supply is typically used in industrial settings and is capable of providing the necessary power to operate the crane's motors and other components.

It's important to note that the specific 10 ton overhead crane power requirement may vary depending on factors such as the crane's design, the weight of the load being lifted, and the operating environment.

Other factors that can impact the 10 ton bridge crane electrical requirements include the length of the runway, the height of the lift, and the speed of the hoist and trolley. Additionally, it's important to ensure that the power supply is capable of providing enough current to meet the crane's demands.

If you have any other specific questions about 10 ton overhead crane power requirements, feel free to let me know and I'll do my best to provide more information.

Services of Dongqi Group 10 ton overhead crane:

Dongqi Group is committed to providing customers with high-quality overhead crane products and excellent after-sales service. Here is some information about Dongqi Group's service:

- Professional team: Dongqi Group has a professional after-sales service team with rich experience and skills in the eot crane industry, who can help customers solve various problems.

- Fast response: Dongqi Group promises to provide solutions in the shortest possible time after customers raise any issues to ensure that their production is not affected.

- Global network: Dongqi Group has an extensive sales network and service support worldwide, providing customers with support and service at any time.

- After-sales service: Dongqi Group also provides after-sales service to help customers understand how to use and maintain their overhead cranes correctly, thereby extending their service life.