Different Types of 10 Ton Overhead Crane for Sale:

| Overhead Crane Types |

Lifting Capacity(t) |

Span(m) |

Voltage(V) |

Price(USD) |

| Single Girder Overhead Crane |

10 t |

7.5~28.5m |

220-480/3/50 |

$4,000 to $50,000 |

| Double Girder Overhead Crane |

10 t |

10.5~35.5m |

220-480/3/50 |

$6,500 to $70,000 |

| Top-Running Overhead Crane |

10 t |

10.5~31.5m |

220-480/3/50 |

$5,000 to $30,000 |

| Underhung Overhead Crane |

10 t |

3~15m |

220-480/3/50 |

$4,200 to $40,000 |

| Low Headroom Single Girder Overhead Crane |

10 t |

7.5~22.5m |

220-480/3/50 |

$4,000 to $45,000 |

| Ladle Overhead Crane |

10 t |

10.5~31.5m |

220-480/3/50 |

$4,500 to $60,000 |

| Explosion-Proof Bridge Crane |

10 t |

7.5~31.5m |

220-480/3/50 |

$6,000 to $50,000 |

| Electromagnetic Overhead Crane |

10 t |

10.5~31.5m |

220-480/3/50 |

$4,000 to $50,000 |

| Overhead Crane with Hook |

10 t |

10.5~35.5m |

220-480/3/50 |

$5,500 to $70,000 |

| Grab Bucket Overhead Crane |

10 t |

10.5~34.5m |

220-480/3/50 |

$5,000 to $50,000 |

| Insulation Overhead Crane |

10 t |

10.5~31.5m |

220-480/3/50 |

$4,000 to $60,000 |

10 ton overhead crane for sale solutions:

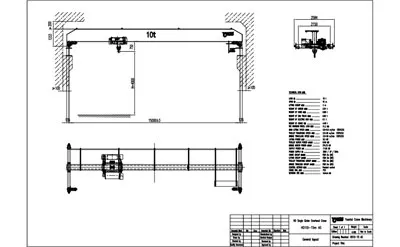

10 ton Single Girder Overhead Crane for Sale:

10 ton Single Girder Overhead Crane for Sale:

Application: Ideal for light to moderate lifting tasks.

Common Uses: Warehouses, workshops, and manufacturing facilities with relatively lower load requirements.

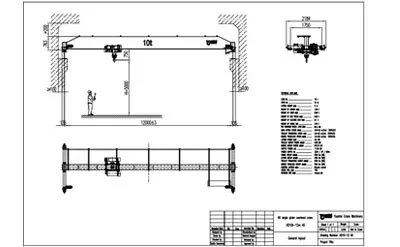

10 ton Double Girder Overhead Crane for Sale:

10 ton Double Girder Overhead Crane for Sale:

Application: Suitable for heavy-duty lifting applications.

Common Uses: Steel mills, power plants, shipbuilding yards, and other industries with high load capacities.

10 ton Top-Running Overhead Crane for Sale:

10 ton Top-Running Overhead Crane for Sale:

Application: Versatile and used for various lifting tasks.

Common Uses: Manufacturing plants, warehouses, and facilities requiring flexibility in load handling.

10 ton Underhung Overhead Crane for Sale:

10 ton Underhung Overhead Crane for Sale:

Application: Designed to run on the bottom flange of runway beams.

Common Uses: Facilities with limited headroom, such as storage areas or workshops.

10 ton Low Headroom Single Girder Overhead Crane for Sale:

10 ton Low Headroom Single Girder Overhead Crane for Sale:

Application: Specifically designed for applications with limited vertical space.

Common Uses: Work areas with low ceilings, such as maintenance shops or warehouses.

10 ton Ladle Overhead Crane for Sale:

10 ton Ladle Overhead Crane for Sale:

Application: Specialized for handling ladles in foundries and steel mills.

Common Uses: Foundries and metal processing facilities where molten metal is transported.

10 ton Explosion-Proof Bridge Crane for Sale:

10 ton Explosion-Proof Bridge Crane for Sale:

Application: Designed to operate in hazardous environments where explosive gases or materials are present.

Common Uses: Chemical plants, oil and gas refineries, and other hazardous industrial settings.

10 ton Electromagnetic Overhead Crane for Sale:

10 ton Electromagnetic Overhead Crane for Sale:

Application: Equipped with electromagnetic lifting mechanisms for handling magnetic materials.

Common Uses: Scrap yards, metal recycling facilities, and industries dealing with ferrous materials.

10 ton Overhead Crane with Hook for Sale:

10 ton Overhead Crane with Hook for Sale:

Application: General-purpose overhead crane with a hook for versatile load handling.

Common Uses: Manufacturing facilities, warehouses, and assembly lines.

10 ton Grab Bucket Overhead Crane for Sale:

10 ton Grab Bucket Overhead Crane for Sale:

Application: Fitted with a grab bucket for bulk material handling.

Common Uses: Bulk material handling in industries such as mining, shipyards, and construction.

10 ton Insulation Overhead Crane for Sale:

10 ton Insulation Overhead Crane for Sale:

Application: Equipped with insulation features for handling materials in environments with temperature variations.

Common Uses: Foundries, glass manufacturing, and other industries where temperature control is crucial.

Features and Benefits of 10 Ton Overhead Crane for Sale:

The key features and benefits of a 10 ton bridge crane make it a valuable asset for material handling and lifting applications in various industries. Here are some notable features and benefits:

- Versatility: Suitable for a wide range of applications across industries, including manufacturing, construction, warehouses, and assembly lines.

- Increased Productivity: Enables efficient and quick lifting and movement of heavy loads, contributing to increased productivity in material handling processes.

- Improved Safety: Designed with safety features such as overload protection, emergency stop buttons, and secure control systems to enhance workplace safety during lifting operations.

- Cost-Effective: Provides a cost-effective solution for handling heavy loads compared to alternative methods, reducing manual labor and the need for multiple smaller lifting devices.

- Customization Options: Offers customization options to meet specific requirements, including variations in span, lifting height, and control systems tailored to the needs of the facility.

- Space Efficiency: Utilizes overhead space efficiently, allowing for floor space optimization and better organization within the facility.

- Reliability and Durability: Built to withstand heavy usage and harsh industrial environments, ensuring a reliable and durable solution for material handling over the long term.

Understanding these key features and benefits helps businesses make informed decisions when considering the implementation of a 10 ton bridge crane in their operations.

10 Ton Overhead Crane Parts and Components

10 ton overhead crane is mainly composed of main beam, end beams, hoisting mechanism, crane travelling mechanism, control system and electrical equipment. Different components can be engineered to improve the overhead crane capacity and performance. Since the 10 ton overhead crane parts and components greatly affect its performance and durability, it is indeed important to select a overhead crane with the right configurations and features.

- Bridge – it is the unit incorporating one or two main beams and end beams. It is a load-bearing member of the overhead crane and spans the width of the building.

- Hoist – it is used to raise and lower the load using wire rope or chain. The overhead crane hoist is generally powered with electricity.

- Trolley – it is the unit onto which the hoist is mounted.

- Crane travelling mechanism – the crane can run on the top of the runway beam or on the bottom flange of the beam.

- Lifting attachment – the lifted load can be supported using a hook which is connected to the hoist. To handle different types of materials, we offer grab bucket, electromagnetic chuck, carries beam and so on.

- Controls – the overhead crane controls are available with pendant control, wireless remote control and cabin control.

- Electrical equipment – insulated conductor bars or festoon systems bring the power to the overhead crane.

Choosing between 10 Ton Single Girder Overhead Crane and Double Girder Overhead Crane:

Height Clearance and Hook Height:

- Single Girder Crane: Offers less vertical space due to the lower profile of the single girder design, which might be suitable for facilities with limited headroom.

- Double Girder Crane: Provides greater hook height clearance due to the higher profile of the double girder design, making it ideal for lifting taller loads or operating in facilities with higher ceilings.

Stability and Rigidity:

- Single Girder Crane: Offers sufficient stability and rigidity for most light to moderate lifting applications.

- Double Girder Crane: Provides enhanced stability and rigidity, making it better suited for handling heavier loads and performing more demanding lifting tasks with minimal deflection.

Cost Considerations:

- Single Girder Crane: Generally, single girder cranes tend to have lower initial costs compared to double girder cranes, making them more budget-friendly for smaller operations or applications with lighter lifting requirements.

- Double Girder Crane: While double girder cranes typically have higher upfront costs due to their heavier construction and greater load capacities, they may offer better long-term value and durability, especially for heavy-duty industrial applications.

Maintenance and Serviceability:

- Single Girder Crane: Generally easier and less expensive to maintain due to their simpler design and fewer components compared to double girder cranes.

- Double Girder Crane: Requires more comprehensive maintenance procedures and may involve higher maintenance costs due to the additional components and structural complexity.

Consider the specific lifting requirements, operational conditions, and environmental factors of your application when choosing between single girder and double girder 10 ton overhead cranes. For instance, if you need to lift exceptionally heavy loads or operate in a high-demand industrial environment, a double girder crane might be more suitable.

How to Install a 10 Ton Overhead Crane:

Installing a 10 ton overhead crane requires careful planning and expertise to ensure safe and efficient operation. The options provided by our company:

Professional Installation Team:

- Site Assessment: Our team conducts a thorough assessment of the installation site to determine factors such as structural integrity, clearance heights, and electrical requirements.

- Preparation: Prior to installation, the site is prepared according to our specifications, including the installation of runway beams, support structures, and electrical connections.

- Assembly: Our professional installation team assembles the components of the 10 ton overhead crane, including the bridge, end trucks, hoist, and controls, following the manufacturer's instructions and safety protocols.

- Installation: Using specialized equipment and rigging techniques, the crane components are lifted into place and securely fastened to the runway beams and support structures.

- Testing and Calibration: Once installed, the crane undergoes rigorous testing and calibration to ensure proper functionality and alignment. Any adjustments or fine-tuning are made as necessary.

- Training: We provide comprehensive training to the client's staff on the operation and maintenance of the 10 ton overhead crane, emphasizing safety protocols and best practices.

Self-Installation with Support:

- Guidance and Resources: For clients opting to install the crane themselves, we provide a range of resources to facilitate the process. This includes 3D installation videos, detailed instruction manuals, 24-hour online support, and electrical drawings.

- Technical Assistance: Our team is available around the clock to provide guidance and assistance during the installation process, addressing any questions or concerns that may arise.

- Quality Assurance: We ensure that clients have access to all necessary resources and support to install the 10 ton overhead crane correctly and safely, minimizing the risk of errors or complications.

Whether clients choose professional installation or opt for self-installation with support, our priority remains the same: to deliver a high-quality 10 ton overhead crane solution that meets their needs and exceeds their expectations.

10 ton Single Girder Overhead Crane for Sale:

10 ton Single Girder Overhead Crane for Sale: 10 ton Double Girder Overhead Crane for Sale:

10 ton Double Girder Overhead Crane for Sale: 10 ton Top-Running Overhead Crane for Sale:

10 ton Top-Running Overhead Crane for Sale: 10 ton Underhung Overhead Crane for Sale:

10 ton Underhung Overhead Crane for Sale: 10 ton Low Headroom Single Girder Overhead Crane for Sale:

10 ton Low Headroom Single Girder Overhead Crane for Sale: 10 ton Ladle Overhead Crane for Sale:

10 ton Ladle Overhead Crane for Sale: 10 ton Explosion-Proof Bridge Crane for Sale:

10 ton Explosion-Proof Bridge Crane for Sale: 10 ton Electromagnetic Overhead Crane for Sale:

10 ton Electromagnetic Overhead Crane for Sale: 10 ton Overhead Crane with Hook for Sale:

10 ton Overhead Crane with Hook for Sale: 10 ton Grab Bucket Overhead Crane for Sale:

10 ton Grab Bucket Overhead Crane for Sale: 10 ton Insulation Overhead Crane for Sale:

10 ton Insulation Overhead Crane for Sale: