10 Ton Overhead Crane

10 Ton 8.22M Overhead Crane with Steel Structure for Sale to Ethiopia

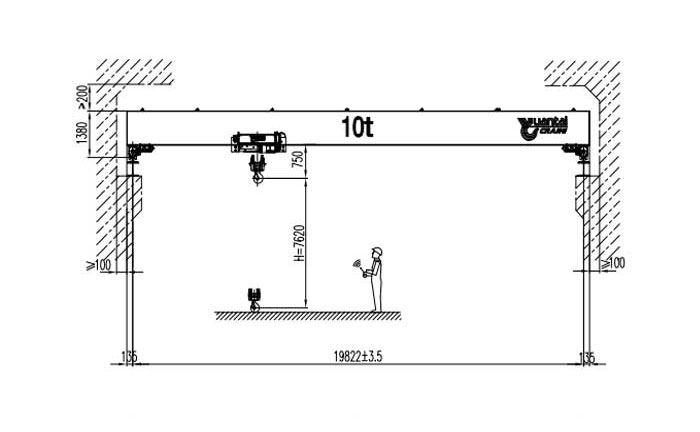

Lifting Capacity: 10 ton

Span: 8.22 m

Lifting Height: 5.6 m

Working Class: A3

Note: We can design and manufacture the crane according your requirments and working conditions.

10 Ton Single Girder Overhead Crane with Steel Structure for Sale to Ethiopia:

- Lifting Capacity: 10 ton,

- Span: 8.22m,

- Lifting Height: 5.6m,

- Working Class: A3

Upon receiving the inquiry about 10 ton overhead crane from Ethiopia, our team engaged in thorough communication with the client to understand their needs comprehensively. After detailed discussions and consultations, we provided the Ethiopia client with a tailored solution that aligned perfectly with their requirements. Our engineers meticulously designed the 10 ton overhead crane system, ensuring optimal performance and safety.

Once the design was approved, the Ethiopia client swiftly proceeded with the preparation of the foundation for the 10 ton overhead crane columns, following our engineer's specifications. With the foundation in place, we expedited the delivery process to meet the client's timeline and requirements. Our efficient logistics and coordination ensured that the 10 ton overhead crane was delivered promptly and in pristine condition to the client's location in Ethiopia.

This case serves as a testament to our expertise in the 10 ton overhead crane industry and our dedication to exceeding client expectations. We look forward to continued partnerships and opportunities to contribute to the success of businesses in Ethiopia and beyond.

Key Components of 10 Ton Single Girder Overhead Crane:

- Girder: The main horizontal beam that supports the trolley and hoist. In a single girder crane, there is one girder.

- End Carriages: These are attached to the ends of the girder and house the wheels on which the crane travels along the runway beam.

- Hoist: The lifting mechanism responsible for raising and lowering the load. It typically consists of a motor, gearbox, drum, and lifting hook or other attachment.

- Trolley: The mechanism that moves horizontally along the girder, carrying the hoist and load.

- Runway Beam: The beam on which the crane travels. It is typically supported by the building structure or columns.

- Electrical Components: These include the power supply system, control panel, limit switches, and safety features like overload protection.

Maintenance Tips of 10 Ton Single Girder Overhead Crane:

- Regular Inspection: Conduct routine inspections of all components to check for wear, damage, or any signs of malfunction. This includes inspecting the girder, end carriages, hoist, trolley, and electrical components.

- Lubrication: Keep all moving parts of 10 ton single girder overhead crane well-lubricated to reduce friction and wear. Follow manufacturer recommendations for the type and frequency of lubrication.

- Tighten Loose Bolts: Check and tighten any loose bolts or connections to ensure structural integrity.

- Check Electrical Components: Inspect electrical wiring, connections, and components for signs of wear, corrosion, or damage. Ensure that all electrical systems of 10 ton single girder overhead craneare functioning properly.

- Monitor Load Capacity: Avoid overloading the 10 ton single girder overhead crane beyond its rated capacity, as this can cause damage to the components and compromise safety.

- Cleanliness: Keep the crane and its components clean from dust, debris, and other contaminants that can cause corrosion or interfere with operation.

- Training: Ensure that operators and maintenance personnel are properly trained in the safe operation and maintenance of the crane.

- Emergency Preparedness: Have procedures in place for handling emergencies, such as equipment failure or power outages, to minimize downtime and ensure the safety of personnel.

- Keep Records: Maintain detailed records of maintenance activities, inspections, and any repairs or replacements performed on the 10 ton single girder overhead crane.

By following these maintenance tips, you can ensure the safe and efficient operation of your 10 ton single girder overhead crane, prolong its lifespan, and minimize downtime due to unexpected failures.

Benefits of 10 Ton Single Girder Overhead Crane:

- Heavy Lifting Capacity: these 10 ton overhead cranes are ideal for handling heavy materials and equipment, enhancing productivity in industrial settings.

- Space Efficiency: 10 ton overhead crane utilize vertical space effectively, freeing up floor space for other operations and storage, thus optimizing workspace layout.

- Cost-Effective: Compared to other types of lifting equipment, 10 ton single girder overhead cranes are often more cost-effective to install and maintain, providing a high return on investment.

- Improved Safety: Equipped with safety features such as overload protection and limit switches, these 10 ton overhead crane enhance workplace safety by minimizing the risk of accidents during lifting operations.

- Long Lifespan: With proper maintenance, 10 ton overhead crane have a long lifespan, providing reliable performance over many years of operation.

Applications of 10 Ton Single Girder Overhead Crane in Ethiopia:

- Infrastructure Development: Ethiopia is investing in infrastructure projects such as road construction, building construction, and expansion of ports and airports. A 10 ton single girder overhead crane can be used in construction projects to lift and move heavy materials like steel beams, concrete panels, and construction equipment.

- Manufacturing and Industrial Sector: Ethiopia aims to boost its manufacturing and industrial sectors to diversify the economy and create employment opportunities. A 10 ton single girder overhead crane can be utilized in manufacturing plants for lifting heavy machinery, raw materials, and finished products.

- Agricultural Processing and Storage: Agriculture is a significant sector in Ethiopia. 10 ton single girder overhead crane can be used in agricultural processing plants and warehouses for lifting and moving bulk agricultural products such as grains, fertilizers, and machinery.

- Logistics and Distribution: With the expansion of trade and investment in Ethiopia, there is a growing need for efficient logistics and distribution networks. 10 ton single girder overhead crane can play a crucial role in warehouses, distribution centers, and freight yards for loading and unloading cargo, handling shipping containers, and facilitating smooth logistics operations.

- Mining and Extractive Industries: Ethiopia is rich in natural resources, including minerals and metals. 10 ton single girder overhead crane can be employed in mining operations for lifting and transporting heavy equipment, ore, and other materials.