Ton Overhead Crane & Price

10 Ton Overhead Crane Price

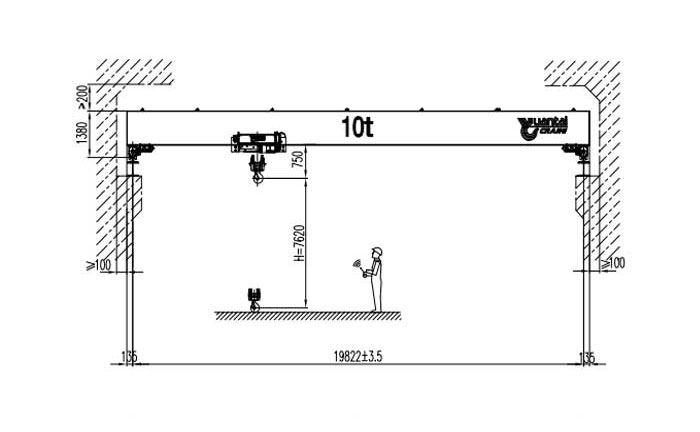

Lifting Capacity: 10 ton

Span: 7.5~31.5 m

Lifting Height: 6-30 m

Working Class: A3, A4, A5

Note: We can design and manufacture the crane according your requirments and working conditions.

Different Types of 10 Ton Overhead Crane Price:

10 ton Single Girder Overhead Crane Price:

10 ton Single Girder Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:7.5~28.5m

- Voltage(V): 220-480/3/50

- Price(USD):$4,000 to $50,000

Common Uses: Warehouses, workshops, and manufacturing facilities with relatively lower load requirements.

10 ton Double Girder Overhead Crane Price:

10 ton Double Girder Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:10.5~35.5m

- Voltage(V): 220-480/3/50

- Price(USD):$6,500 to $70,000

Common Uses: Steel mills, power plants, shipbuilding yards, and other industries with high load capacities.

10 ton Top-Running Overhead Crane Price:

10 ton Top-Running Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:10.5~31.5m

- Voltage(V): 220-480/3/50

- Price(USD):$5,000 to $30,000

Common Uses: Manufacturing plants, warehouses, and facilities requiring flexibility in load handling.

10 ton Underhung Overhead Crane Price:

10 ton Underhung Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:3~15m

- Voltage(V): 220-480/3/50

- Price(USD):$4,200 to $40,000

Common Uses: Facilities with limited headroom, such as storage areas or workshops.

10 ton Low Headroom Single Girder Overhead Crane Price:

10 ton Low Headroom Single Girder Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:7.5~22.5m

- Voltage(V): 220-480/3/50

- Price(USD):$4,000 to $45,000

Common Uses: Work areas with low ceilings, such as maintenance shops or warehouses.

10 ton Ladle Overhead Crane Price:

10 ton Ladle Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:10.5~31.5m

- Voltage(V): 220-480/3/50

- Price(USD):$4,500 to $60,000

Common Uses: Foundries and metal processing facilities where molten metal is transported.

10 ton Explosion-Proof Bridge Crane Price:

10 ton Explosion-Proof Bridge Crane Price:

- Lifting Capacity; 10 ton

- Span:7.5~31.5m

- Voltage(V): 220-480/3/50

- Price(USD):$6,000 to $50,000

Common Uses: Chemical plants, oil and gas refineries, and other hazardous industrial settings.

10 ton Electromagnetic Overhead Crane Price:

10 ton Electromagnetic Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:10.5~31.5m

- Voltage(V): 220-480/3/50

- Price(USD):$4,000 to $50,000

Common Uses: Scrap yards, metal recycling facilities, and industries dealing with ferrous materials.

10 ton Overhead Crane with Hook Price:

10 ton Overhead Crane with Hook Price:

- Lifting Capacity; 10 ton

- Span:10.5~35.5m

- Voltage(V): 220-480/3/50

- Price(USD):$5,500 to $70,000

Common Uses: Manufacturing facilities, warehouses, and assembly lines.

10 ton Grab Bucket Overhead Crane Price:

10 ton Grab Bucket Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:10.5~34.5m

- Voltage(V): 220-480/3/50

- Price(USD):$5,000 to $50,000

Common Uses: Bulk material handling in industries such as mining, shipyards, and construction.

10 ton Insulation Overhead Crane Price:

10 ton Insulation Overhead Crane Price:

- Lifting Capacity; 10 ton

- Span:10.5~31.5m

- Voltage(V): 220-480/3/50

- Price(USD):$4,000 to $60,000

Common Uses: Foundries, glass manufacturing, and other industries where temperature control is crucial.

Key components of a 10 ton overhead crane include:

- Bridge: The bridge is the horizontal beam that spans the width of the working area. It typically moves along parallel runways, allowing the crane to cover the entire length of the facility.

- Hoist: The hoist is the lifting mechanism attached to the bridge. It consists of a motorized drum or winch and a hook or other lifting attachment. The hoist is responsible for raising and lowering the load.

- End Trucks: End trucks are the components that support the bridge and allow it to move along the runways. They typically contain wheels or tracks that run on the runway beams.

- Runway System: The runway system consists of parallel beams that support the movement of the bridge. The bridge, along with the hoist, moves along these runways to position the load.

- Control System: Overhead cranes are operated using a control system, which can be a pendant control with a cable or a remote control system. This allows the crane operator to control the movement of the crane, including lifting, lowering, and horizontal travel.

- Steel Structure: The entire crane is typically constructed from sturdy steel to ensure strength and durability. This includes the bridge, end trucks, and other structural components.

The 10 ton capacity indicates the maximum weight that the crane is designed to lift. It's important to note that the actual lifting capacity may vary based on factors such as the span of the crane, the lifting height, and the specific design of the crane.

10 ton overhead cranes for sale are used in a variety of industries for tasks such as loading and unloading materials, assembling heavy equipment, and transporting large items within a facility. 10 ton bridge crane play a crucial role in improving efficiency and safety in material handling processes. The selection of a 10 ton overhead crane should be based on the specific lifting requirements and operational conditions of the facility where it will be used.

Features and Benefits of 10 Ton Overhead Crane:

The key features and benefits of a 10 ton bridge crane make it a valuable asset for material handling and lifting applications in various industries. Here are some notable features and benefits:- Versatility: Suitable for a wide range of applications across industries, including manufacturing, construction, warehouses, and assembly lines.

- Increased Productivity: Enables efficient and quick lifting and movement of heavy loads, contributing to increased productivity in material handling processes.

- Improved Safety: Designed with safety features such as overload protection, emergency stop buttons, and secure control systems to enhance workplace safety during lifting operations.

- Cost-Effective: Provides a cost-effective solution for handling heavy loads compared to alternative methods, reducing manual labor and the need for multiple smaller lifting devices.

- Customization Options: Offers customization options to meet specific requirements, including variations in span, lifting height, and control systems tailored to the needs of the facility.

- Space Efficiency: Utilizes overhead space efficiently, allowing for floor space optimization and better organization within the facility.

- Reliability and Durability: Built to withstand heavy usage and harsh industrial environments, ensuring a reliable and durable solution for material handling over the long term.

Understanding these key features and benefits helps businesses make informed decisions when considering the implementation of a 10 ton bridge crane in their operations.

10 Ton Overhead Crane for Sale Application:

10 ton overhead crane for sale are versatile lifting solutions suitable for various applications and industries that involve the handling of heavy loads. Here are some common applications and industries that benefit from the use of 10 ton overhead crane:

- Manufacturing: Assembly lines and manufacturing facilities use 10 ton bridge Crane for lifting and moving heavy components, machinery, and materials.

- Construction: Construction sites employ 10 ton overhead crane for tasks such as lifting steel beams, concrete panels, and other construction materials.

- Warehousing: Warehouses utilize overhead crane for efficient loading and unloading of heavy pallets, machinery, and other large items.

- Automotive Industry: Car manufacturing plants use 10 ton overhead crane for sale to handle large and heavy automotive components during the production process.

- Steel Mills: Steel mills and metal fabrication facilities utilize overhead crane for lifting and transporting raw materials, semi-finished products, and finished steel products.

- Shipbuilding: Shipyards employ overhead crane for lifting and moving ship components, engines, and other heavy materials during the shipbuilding process.

- Aerospace Industry: Aerospace manufacturing facilities use overhead crane for handling large and heavy aircraft components with precision.

- Power Plants: Power generation facilities use overhead crane for the installation and maintenance of heavy equipment, such as turbines and generators.

- Mining: Mining operations utilize overhead crane for lifting and moving heavy loads, including minerals, equipment, and machinery.

- Foundries: Foundries use overhead crane for handling molten metal, molds, and heavy castings in various stages of the production process.

- Paper Mills: Paper manufacturing facilities use bridge Crane for handling large paper rolls, machinery, and other materials in the production process.

- Renewable Energy Projects: Wind and solar energy projects may use overhead crane for the installation of large components, such as wind turbine components or solar panels.

- Logistics and Distribution Centers: Large logistics and distribution centers utilize overhead crane for efficient material handling, especially when dealing with heavy goods.

- Heavy Equipment Maintenance: Facilities involved in the maintenance and repair of heavy equipment, such as construction machinery, may use bridge Crane for lifting and positioning components.

- Infrastructure Projects: Large infrastructure projects, such as bridge construction, may require the use of overhead crane for lifting and placing heavy structural elements.

These examples illustrate the widespread use of 10 ton overhead crane for sale across industries that involve heavy lifting and material handling, contributing to increased efficiency and safety in various work environments.