Projects

Metallurgic Electric Single Girder Overhead Crane

Lifting Capacity: 1-10 ton

Span: 7.5-28.5 m

Lifting Height: 1-30 m

Working Class: A5,A6

Note: We can design and manufacture the crane according your requirments and working conditions.

Metallurgic electric single girder overhead crane is a common type of lifting machinery, widely used in industries such as steel, metallurgy, and shipbuilding. It consists of a single girder bridge, lifting machinery, electrical equipment, and other components. Metallurgic electric single girder overhead crane is powered by electricity and has the characteristics of smooth operation, low noise, and low energy consumption. It has a simple structure, easy installation, and is suitable for various indoor and outdoor locations. The rated lifting capacity of the metallurgic electric single girder overhead crane is usually between 1 and 10 tons, but it can also be customized according to customer requirements. Metallurgic electric single girder overhead crane crane is widely used in factories, warehouses, docks, and other places, and can be used for lifting steel, pipes, machinery equipment, and other items.

Metallurgic electric single girder overhead crane structure and features:

Metallurgic electric single girder overhead crane is mainly composed of a bridge, crane traveling mechanism, metallurgy hoist, and electrical equipment.

- Bridge: The bridge is used for supporting the crane and longitudinal traverse, and it is composed of the main girder, end truck, and connector. The main girder is made of high-quality molding and stamping I-beam and U-Steel, and adapts special thermal protection process below the main girder. The steel quality is Q235B or Q345B (international Fe37 or Fe52), while the end truck is welded by rectangular tube or high-quality steel plate. The connecting between the main girder and end truck adapts bolts suspension or sitting structure, which makes it easy for transportation.

- Crane Traveling Mechanism: The crane traveling mechanism adopts a separate driving system, and the driving and braking are completed by a tapered rotor motor, which reduces damage to the rail caused by wheel skew or deflection.

- Metallurgy hoist: Metallurgy hoist is typically designed to handle heavy loads and operate in high-temperature environments, making it suitable for use in metallurgical plants and other industrial settings. The metallurgy hoist may have specialized features such as heat-resistant materials, dust-proof and explosion-proof designs, and other safety features to ensure safe and efficient operation.

- Electrics: The electrical system allows lifting and traveling to be controlled separately, working separately or at the same time. The power supply of trolley moving adapts thermostability cable, and there are optional power supply ways such as angle steel slide touch line, safe slide touch line, and soft cable slide touch line. The control ways are ground control, but remote control is advised for safety. Through pressing the button switch, the contactor cuts in or cuts off the power. The electric components of the main circuit and control circuit are less, making it easy for maintenance. There is a thermal protective device outside the motor.

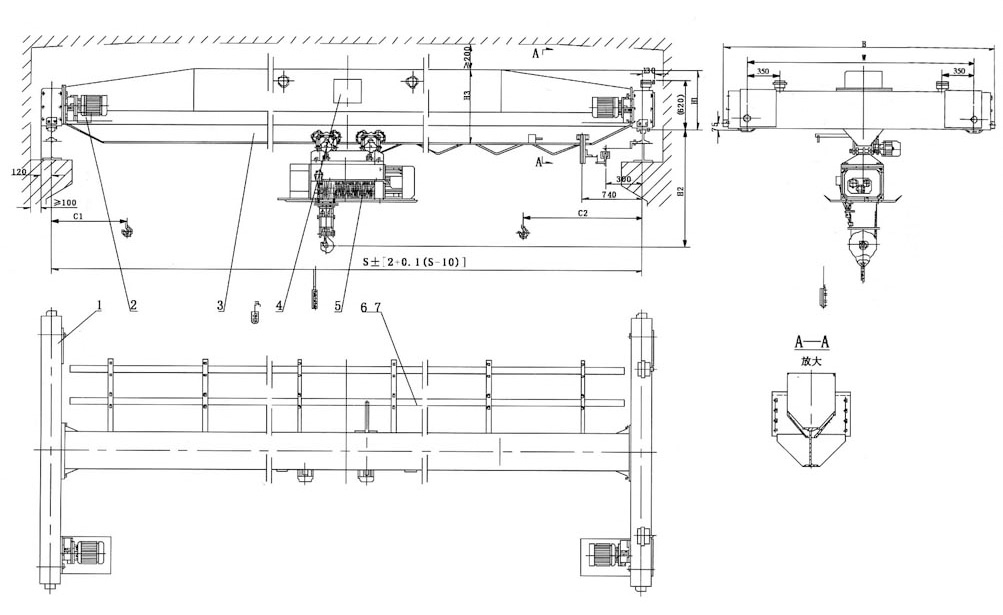

Metallurgic electric single girder overhead crane structure drawing:

The main purpose of metallurgic electric single girder overhead crane:

- Metallurgic electric single girder overhead crane is used in conjunction with the metallurgic electric hoist to perform intermittent and periodic work.

- Metallurgic electric single girder overhead crane can improve labor productivity in metallurgic and casting places in industrial enterprises, achieving fast and efficient material handling and lifting.

- The use of the metallurgic electric single girder overhead crane can reduce the workload of manual material handling, improve work efficiency, and save labor costs.

- Metallurgic electric single girder overhead crane is suitable for various indoor and outdoor sites and can be used for lifting steel, pipes, machinery, and other items. It is widely used in factories, warehouses, docks, and other places.

Metallurgical electric single girder overhead crane safe and protection devices:

- Block in the end of track and buffer: This device prevents the crane from derailing by blocking the end of the track. A block with a rubber bumper is installed on the I-beam for trolley moving to protect the crane from collision. The end truck has a polyurethane buffer and an over-travel limiter to ensure the crane stops traveling in the condition of power off.

- Position limiter: This device limits the traveling of the machine and prevents accidents. The metallurgy hoist has a position limiter of rising and falling, which includes LX type and hammer type cut off limiter. When the hook is in the lowest position, it can cut off the power automatically, stop running, and ensure the wire rope twining on the coiling block is not less than 2 circles. The rising position limiter is used for limiting the height of hook lifting, preventing accidents caused by clashing top and breaking the wire rope.

- Overload limiter: Overloading can lead to breakage of wire rope, damage to components, motor, and brake. The overload limiter is one protective device to prevent the hoist from overloading during working. When the lifting capacity reaches the rated 95%~100%, the overload limiter sends out sound and light alarm signals. When the lifting capacity exceeds the rated lifting weight, overload limiter will cut off the lifting power automatically and send out a forbidden signal to prevent damage to components and accidents. It's important to note that using overload limiter should not reduce the lifting capacity, and the setting point should be adjusted to lift rated lifting weight in normal condition. Also, overload protection action point should be less than 1.1 times of rated lifting weight, and setting point can be adjusted between 1.0~1.05 times of rated lifting weight in any condition.