Different Types of 5 Ton Electric Chain Hoist Specification for Sale:

5 Ton Motorized Trolley Electric Chain Hoist for Sale

5 Ton Motorized Trolley Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Hook type Electric Chain Hoist for Sale

5 Ton Hook type Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Low Headroom Electric Chain Hoist for Sale

5 Ton Low Headroom Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 3-130 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Manual Trolley Electric Chain Hoist for Sale

5 Ton Manual Trolley Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton European Electric Chain Hoist for Sale

5 Ton European Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 1 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Manual Chain Hoist for Sale

5 Ton Manual Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 0.5~3.5m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Double Hook Electric Chain Hoist for Sale

5 Ton Double Hook Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height:According your demands

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Explosion-proof Electric Chain Hoist for Sale

5 Ton Explosion-proof Electric Chain Hoist for SaleCapacity: 5 Ton

Lifting height: 3/6/9/12/18 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Safety First: Essential Safety Features of a 5 Ton Electric Chain Hoist

When it comes to using a 5 ton electric chain hoist, safety is paramount. Here are some essential safety features to look for:

- Overload Protection: This feature prevents the 5 ton electric chain hoist from lifting loads that exceed its rated capacity, reducing the risk of mechanical failure.

- Emergency Stop Button: An easily accessible emergency stop allows operators to quickly halt operations in case of an emergency.

- Limit Switches: These switches automatically stop the 5 ton electric chain hoist at predetermined upper and lower limits to prevent over-travel and potential accidents.

- Braking System: A reliable braking system is crucial for holding loads securely in place, especially during lifting and lowering.

- Load Chain and Hook Safety Latches: High-quality load chains and hooks equipped with safety latches help prevent accidental detachment of loads.

- Chain Locking Mechanism: A mechanism to lock the chain when not in use prevents unintentional movement.

- Thermal Overload Protection: This feature protects the motor from overheating, which can occur during prolonged use or if overloaded.

- Durable Housing: A robust, weather-resistant housing protects the 5 ton electric chain hoist from dust, debris, and environmental factors that could compromise safety.

5 Ton Electric Chain Hoists: Features, Benefits

Electric chain hoists are essential tools in various industries, from construction to manufacturing. A 5 ton electric chain hoist strikes a balance between capacity and versatility, making it a popular choice for many applications.

Features

1. Load Capacity5-Ton Rating: Specifically designed to lift heavy loads up to 5 tons, suitable for a wide range of materials and equipment.

2. Lifting HeightVaried Heights: Many models of 5 ton electric chain hoist offer customizable lifting heights, allowing flexibility based on the application.

3. Power SourceElectric Motor: Utilizes a powerful electric motor for efficient lifting, eliminating the need for manual effort.

Voltage Options: Available in various voltage options (e.g., 230V, 400V) to suit different power supply requirements.

4. Chain DesignHigh-Strength Chain: Equipped with durable, high-strength chains to handle heavy loads and ensure safety.

Anti-Twist Features: Many models of 5 ton electric chain hoist feature anti-twist chains to prevent entanglement during lifting.

5. ControlsRemote Control Options: Wireless remote controls for easy operation from a distance, enhancing safety and convenience.

Pendant Controls: Many 5 ton electric chain hoist come with a pendant control option for manual operation close to the load.

6. Durability and Build QualityRobust Construction: Built with high-quality materials designed to withstand heavy use and harsh environments.

Corrosion Resistance: Many 5 ton electric chain hoist come with coatings or finishes that resist corrosion and wear.

7. Portability and InstallationCompact Design: Often designed to be lightweight and portable, allowing easy relocation.

Ease of Installation: Generally straightforward to install, often requiring minimal tools.

Benefits

- Increased Efficiency: 5 ton electric chain hoist significantly reduce the time and effort required to lift heavy loads, improving overall productivity.

- Enhanced Safety: With built-in safety features, 5 ton electric chain hoist minimize the risk of accidents associated with manual lifting.

- Versatility: Suitable for various applications, including construction, warehouses, factories, and shipping yards.

- Cost-Effectiveness: Investing in an 5 ton electric chain hoist can lead to long-term savings by reducing labor costs and increasing operational efficiency.

- Low Maintenance: Designed for durability, 5 ton electric chain hoist typically require less maintenance compared to manual chain hoist, saving time and money.

- User-Friendly: Easy to operate, even for individuals with limited experience in lifting equipment, thanks to intuitive controls and designs.

- Adaptability: Many 5 ton electric chain hoist offer options for customization, including attachments and accessories to suit specific lifting needs.

A 5 ton electric chain hoist is an invaluable tool for any business that requires efficient and safe lifting of heavy loads. With a range of features designed for reliability and safety, it can enhance productivity while reducing the risk of injury. When choosing a 5 ton electric chain hoist, consider factors such as lifting height, power requirements, and specific features to find the best fit for your needs.

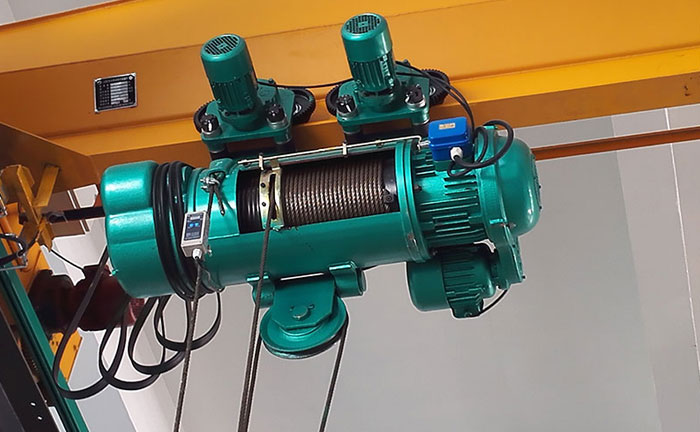

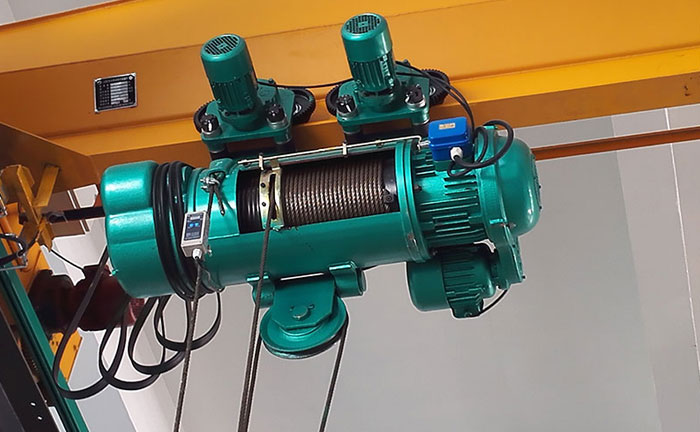

Different Types of 5 Ton Electric Wire Rope Hoist Specification for Sale:

5 Ton Single Speed Electric Wire Rope Hoist for Sale

5 Ton Single Speed Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Double Speed Electric Wire Rope Hoist for Sale

5 Ton Double Speed Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Low Headroom Electric Wire Rope Hoist for Sale

5 Ton Low Headroom Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 3~60m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Explosion-proof Electric Wire Rope Hoist for Sale

5 Ton Explosion-proof Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 3~100m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Metallurgical Electric Wire Rope Hoist for Sale

5 Ton Metallurgical Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 6~18m

Working Duty:M3

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale

5 Ton European standard Low Headroom Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 6m-50m

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale

5 Ton Single & Double Girder European Style Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height:1-120M

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

5 Ton Double Hook Electric Wire Rope Hoist for Sale

5 Ton Double Hook Electric Wire Rope Hoist for SaleCapacity: 5 Ton

Lifting height: 6-100m

Working Duty:M3, M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

What You Need to Know About 5 Ton Electric Wire Rope Hoists:

1. Load Capacity: Designed to lift loads up to 5 tons (10,000 pounds), making them suitable for various heavy-duty applications.

2. Types of Hoists

Single Phase vs. Three Phase: Single-phase hoists are suitable for smaller operations, while three-phase hoists offer higher power for industrial settings.

Fixed vs. Portable: Fixed hoists are mounted in one location, while portable models can be moved as needed.

3. Lifting Mechanism

Wire Rope: Made from durable steel, wire ropes are strong and designed for heavy lifting. Ensure the rope has a sufficient safety factor.

Drum Construction: A robust drum design is essential for efficient rope winding and minimizing wear.

4. Speed and Control: Look for 5 ton electric wire rope hoist with variable speed options for better control during lifting and lowering operations.

5. Safety Features

Overload Protection: Prevents lifting beyond the hoist's capacity.

Limit Switches: Automatically stop the hoist at the maximum height to prevent accidents.

Emergency Stop: Allows for quick halting of operations in emergencies.

6. Installation and Operation: Requires appropriate mounting and setup, usually on overhead beams or gantries. Ensure your workspace is suitable for installation.

7. Maintenance Requirements: Regular maintenance is crucial for safety and longevity of 5 ton electric wire rope hoist. Check lubrication, wear on the rope, and mechanical parts frequently.

8. Applications: 5 ton electric wire rope hoist commonly used in warehouses, construction sites, factories, and any environment requiring heavy lifting.

9. Environmental Considerations: Choose 5 ton electric wire rope hoist rated for specific environments (e.g., weather-resistant for outdoor use, explosion-proof for hazardous areas).

10. Cost Factors: Prices of 5 ton electric wire rope hoist can vary based on brand, features, and materials. Consider both initial costs and long-term maintenance expenses.

Different Types of 5 Ton Electric Hoist Price:

Prices for 5 ton electric hoist can vary based on factors such as brand, features, and additional capabilities. 5 ton electric hoist prices ranging from a few hundred to a few thousand dollars, depending on the complexity and specifications of the hoist.

| Electric Hoist(t) |

Lifting Height(m) |

Power Supply(V) |

Price(USD) |

| 5 Ton Electric Chain Hoist |

3~50 |

220-480/3/50 |

$5000~20000 |

| 5 Ton Electric Wire Rope Hoist |

3~50 |

220-480/3/50 |

$5000~20000 |

Different Types of Electric Hoist Price:

The electric hoist price can vary widely depending on several factors, including the hoist's capacity, brand, quality, and where you purchase it. In general, electric hoist price can range from a few hundred dollars to several thousand dollars. Here are some approximate electric hoist price ranges based on hoist capacity:

European-spec electric hoist price

European-spec electric hoist are known for their quality and safety features. European-spec electric hoist price can range from $1,000 to $5,000 or more.

Single speed wire rope electric hoist price

Single-speed wire rope electric hoist typically single speed wire rope electric hoist cost between $500 and $3,000.

Double Speed Wire Rope Electric Hoist Price

Double-speed wire rope electric hoist price higher than single-speed models and double speed wire rope electric hoist price from $1,000 to $5,000 or more.

Explosion-proof electric hoist price

Explosion-proof electric hoist are designed for hazardous environments and safety. Explosion-proof electric hoist price can vary significantly but generally range from $2,000 to $10,000 or more.

Electric chain hoist price

Electric chain hoist are often more affordable than wire rope hoist. Electric chain hoist price typically range from $300 to $2,000 or more.

Metallurgical electric hoist price

Metallurgical hoist are designed for heavy-duty applications. Metallurgical electric hoist price can range from $2,000 to $10,000 or more.

Traditional Electric Hoist Trolley price

Traditional electric hoist trolleys are often more affordable, with traditional electric hoist trolley price ranging from $300 to $1,500 or more.

European-spec Electric Hoist Trolley price

European-spec electric hoist trolleys are known for their quality and safety features and European-spec electric hoist trolleys price from $1,000 to $5,000 or more.

Comparing Electric Hoists: 5 Ton vs. Other Load Capacities

1. Load Capacity

5 Ton Hoist: 5 ton electric hoist suitable for heavy-duty lifting tasks in construction, manufacturing, and shipping. It's ideal for moving large machinery, structural components, or bulk materials.

Other Capacities: Common capacities include 1 ton, 2 tons, and 10 tons. Lower capacities are more suited for lighter applications, such as maintenance work or smaller machinery, while higher capacities cater to specialized industries like heavy construction or mining.

2. Motor Size and Power

5 Ton Hoist: Typically features a more powerful motor to handle the increased load, which may result in higher energy consumption.

Other Capacities: Smaller electric hoist have smaller motors, resulting in lower power requirements and potentially lower operating costs.

3. Safety Features

5 Ton Hoist: 5 ton electric hoist often equipped with advanced safety features, such as overload protection, emergency stop buttons, and limit switches, to prevent accidents due to heavy loads.

Other Capacities: While they also have safety features, the requirements may be less stringent due to lighter loads.

4. Cost

5 Ton Hoist: Higher initial purchase price due to 5 ton electric hoist robust construction and features, but may offer better value in heavy-use environments.

Other Capacities: Generally more affordable, making them accessible for small businesses or less demanding applications.

5. Applications

5 Ton Hoist: Ideal for construction sites, industrial environments, and warehouses where heavy lifting is frequent.

Other Capacities: Better suited for home workshops, automotive repairs, or lighter industrial tasks.

6. Speed and Lifting Height

5 Ton Hoist: May 5 ton electric hoist have a slower lifting speed due to the weight but can often lift to significant heights.

Other Capacities: Smaller electric hoist might lift faster and are designed for more compact spaces.

Choosing the right 5 ton electric hoist depends on your specific needs, including the weight of the loads you’ll be lifting, frequency of use, and workspace constraints. A 5 ton electric hoist is an excellent choice for heavy-duty applications, while lighter capacities serve well in less demanding environments. Consider factors like safety, cost, and portability when making your decision.

Maintenance Tips for Longevity of Your 5 Ton Electric Hoist:

To ensure the longevity of your 5 ton electric hoist, follow these maintenance tips:

- Regular Inspections: Check for wear and tear on cables, hooks, and other components. Look for signs of rust or corrosion.

- Lubrication: Keep moving parts lubricated according to the manufacturer’s recommendations. This reduces friction and wear.

- Cleanliness: Regularly clean 5 ton electric hoist to remove dirt, dust, and debris that can affect its operation.

- Load Limits: Always adhere to the specified load capacity to prevent strain on 5 ton electric hoist.

- Electrical Checks: Inspect the wiring and connections for damage or fraying. Ensure electrical components are in good condition.

- Emergency Stop Function: Test the emergency stop feature periodically to ensure it’s functioning correctly.

- Proper Storage: When not in use, store 5 ton electric hoist in a dry, protected area to prevent environmental damage.

- Training: Ensure operators are trained on proper usage and safety protocols to avoid misuse.

Cost Analysis: Investing in a 5 Ton Electric Hoist

When considering the investment in a 5 ton electric hoist, a cost analysis involves multiple factors beyond just the initial purchase price. Here’s a breakdown to help you evaluate the overall investment:

1. Initial Purchase Price

Cost Range: The price of a 5 ton electric hoist typically depending on the brand, features, and capabilities.

Budgeting: Include potential additional costs for accessories, such as slings, hooks, and control systems.

2. Operating Costs

Energy Consumption: Calculate the energy costs associated with operating the 5 ton electric hoist. Consider the motor’s power rating and average usage hours.

Maintenance Expenses: Regular maintenance will incur costs for parts, lubrication, and potentially professional servicing.

3. Training Costs

Operator Training: Invest in training for personnel to ensure safe and effective use, which can prevent accidents and equipment damage.

4. Downtime Costs

Operational Downtime: Consider the potential costs associated with downtime if the 5 ton electric hoist requires repairs. A well-maintained electric hoist reduces downtime.

Replacement Costs: Evaluate the long-term costs of having to replace a hoist due to inadequate maintenance or overuse.

5. Resale Value

Depreciation: Assess the expected depreciation of 5 ton electric hoist over time. A well-maintained electric hoist may retain a higher resale value, providing a better return on investment.

Investing in a 5 ton electric hoist can be a significant upfront cost, but when considering operating, maintenance, and potential downtime costs, it often proves to be a worthwhile investment for businesses that require heavy lifting capabilities. A thorough cost analysis helps in making an informed decision tailored to your specific operational needs.

The Ultimate Guide to 5 Ton Electric Hoist Installation and Operation:

Installation Steps of 5 Ton Electric Hoist

- 1. Site Assessment: Evaluate the location for sufficient space, overhead clearance, and stability. Ensure the area meets load-bearing requirements.

- Mounting Setup: Install the 5 ton electric hoist on a secure beam or support structure. Use appropriate mounting brackets and hardware to ensure stability.

- Electrical Connections: Connect the 5 ton electric hoist to a power source, adhering to local electrical codes. Ensure proper grounding and circuit protection.

- Safety Features: Install safety devices such as limit switches, emergency stop buttons, and overload protection mechanisms.

- Testing: Before regular use, conduct a test lift with a load below the maximum capacity to check functionality and stability.

Operation Tips of 5 Ton Electric Hoist

- Read the Manual: Familiarize yourself with the manufacturer’s operating instructions and safety guidelines.

- Pre-Operational Checks: Inspect the 5 ton electric hoist before each use, checking cables, hooks, and controls for wear or damage.

- Load Management: Always adhere to the 5 ton electric hoist’s load capacity. Distribute loads evenly and use slings or straps for safe lifting.

- Control Operation: Use the control pendant or remote to operate 5 ton electric hoist smoothly. Avoid sudden movements to prevent load swings.

- Communication: Establish clear communication signals between operators and ground personnel to ensure safety during lifts.

- Post-Use Procedures: After use, store the 5 ton electric hoist properly, and perform routine maintenance checks to prepare for future operations.

Common Applications for 5 Ton Electric Hoists in Industry:

- Construction: 5 ton electric hoist lifting heavy materials like steel beams, concrete blocks, and roofing components during building projects.

- Manufacturing: 5 ton electric hoist assisting in assembly lines by moving heavy machinery parts or products between workstations.

- Warehouse Operations: Efficiently lifting and moving pallets, crates, and bulk materials in storage facilities.

- Automotive: 5 ton electric hoist used for lifting vehicles or heavy parts during repairs and maintenance in auto shops.

- Shipbuilding: Assisting in the movement of heavy components and equipment during the construction or repair of ships.

- Mining: 5 ton electric hoist lifting heavy tools and equipment, as well as transporting mined materials within facilities.

- Maintenance: Employed in facilities management for lifting heavy machinery for repairs or installation.

5 Ton Motorized Trolley Electric Chain Hoist for Sale

5 Ton Motorized Trolley Electric Chain Hoist for Sale 5 Ton Hook type Electric Chain Hoist for Sale

5 Ton Hook type Electric Chain Hoist for Sale 5 Ton Low Headroom Electric Chain Hoist for Sale

5 Ton Low Headroom Electric Chain Hoist for Sale 5 Ton Manual Trolley Electric Chain Hoist for Sale

5 Ton Manual Trolley Electric Chain Hoist for Sale 5 Ton European Electric Chain Hoist for Sale

5 Ton European Electric Chain Hoist for Sale 5 Ton Manual Chain Hoist for Sale

5 Ton Manual Chain Hoist for Sale 5 Ton Double Hook Electric Chain Hoist for Sale

5 Ton Double Hook Electric Chain Hoist for Sale 5 Ton Explosion-proof Electric Chain Hoist for Sale

5 Ton Explosion-proof Electric Chain Hoist for Sale 5 Ton Single Speed Electric Wire Rope Hoist for Sale

5 Ton Single Speed Electric Wire Rope Hoist for Sale 5 Ton Double Speed Electric Wire Rope Hoist for Sale

5 Ton Double Speed Electric Wire Rope Hoist for Sale 5 Ton Low Headroom Electric Wire Rope Hoist for Sale

5 Ton Low Headroom Electric Wire Rope Hoist for Sale 5 Ton Explosion-proof Electric Wire Rope Hoist for Sale

5 Ton Explosion-proof Electric Wire Rope Hoist for Sale 5 Ton Metallurgical Electric Wire Rope Hoist for Sale

5 Ton Metallurgical Electric Wire Rope Hoist for Sale 5 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale

5 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale 5 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale

5 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale 5 Ton Double Hook Electric Wire Rope Hoist for Sale

5 Ton Double Hook Electric Wire Rope Hoist for Sale