Ton Overhead Crane & Price

20 Ton Overhead Crane

Lifting Capacity: 20 ton

Span: 7.5~31.5 m

Lifting Height: 6~30 m

Working Class: A4, A5

Note: We can design and manufacture the crane according your requirments and working conditions.

A 20 ton overhead crane is a robust and versatile material handling solution designed for the efficient lifting and movement of heavy loads within industrial and construction environments. Characterized by its substantial lifting capacity of 20 tons, this overhead crane is equipped with a bridge structure that spans the workspace, providing a means to lift and transport materials with precision and reliability. Available in both single girder and double girder configurations, the 20 ton overhead crane plays a pivotal role in optimizing productivity, enhancing safety, and streamlining material handling processes in a variety of applications. From manufacturing plants to warehouses and construction sites, the 20 ton overhead crane is a vital tool, offering a cost-effective and efficient solution for lifting and positioning heavy loads with precision and ease.

Different types of 20 ton overhead crane for sale you can choose:

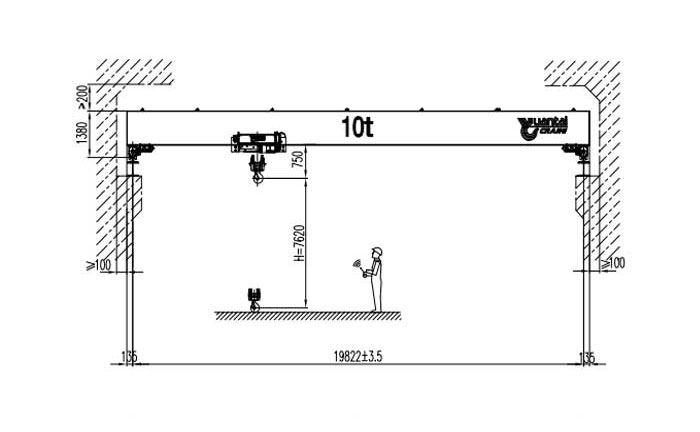

20 ton Single Girder Overhead Crane Price:

20 ton Single Girder Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span(m): 7.5~28.5m

- Power supply(V): 220-480/3/50

- Price: $6,000 - $50,000

20 ton Double Girder Overhead Crane Price:

20 ton Double Girder Overhead Crane Price:

- Lifting capacity (T): 20 ton

- Lifting span: 10.5~35.5m

- Power supply(V): 220-480/3/50

- Price: $8,600 - $95,000

20 ton Top-Running Overhead Crane Price:

20 ton Top-Running Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span(m): 10.5~31.5m

- Power supply(V): 220-480/3/50

- Price: $6,000 - $60,000

20 ton Low Headroom Single Girder Overhead Crane Price:

20 ton Low Headroom Single Girder Overhead Crane Price:

- Lifting capacity (T): 20 ton

- Lifting span: 7.5~22.5m

- Power supply(V): 220-480/3/50

- Price: $6,600 - $50,000

20 ton Ladle Overhead Crane Price:

20 ton Ladle Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span(m): 10.5~31.5m

- Power supply(V): 220-480/3/50

- Price: $7,000 - $60,000

20 ton Explosion-Proof Bridge Crane Price:

20 ton Explosion-Proof Bridge Crane Price:

- Lifting capacity (T): 20 ton

- Lifting span: 7.5~31.5m

- Power supply(V): 220-480/3/50

- Price: $7,000 - $60,000

20 ton Electromagnetic Overhead Crane Price:

20 ton Electromagnetic Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span(m): 10.5~31.5m

- Power supply(V): 220-480/3/50

- Price: $7,500 - $50,000

20 ton Overhead Crane with Hook Price:

20 ton Overhead Crane with Hook Price:

- Lifting capacity (T): 20 ton

- Lifting span: 10.5~35.5m

- Power supply(V): 220-480/3/50

- Price: $8,000 - $60,000

20 ton Grab Bucket Overhead Crane Price:

20 ton Grab Bucket Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span(m): 10.5~34.5m

- Power supply(V): 220-480/3/50

- Price: $7,000 - $50,000

20 ton Insulation Overhead Crane Price:

20 ton Insulation Overhead Crane Price:

- Lifting capacity (T): 20 ton

- Lifting span: 10.5~31.5m

- Power supply(V): 220-480/3/50

- Price: $8,000 - $60,000

20 ton European Single Girder Overhead Crane Price:

20 ton European Single Girder Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span: 6~31.5m

- Power supply(V): 220-480/3/50

- Price: $10,000 - $100,000

20 ton European Double Girder Overhead Crane Price:

20 ton European Double Girder Overhead Crane Price:

- Lifting capacity: 20 ton

- Lifting span: 6~31.5m

- Power supply(V): 220-480/3/50

- Price: $15,000 - $150,000

The prices of 20 ton overhead cranes can vary widely based on factors such as brand, specifications, features, and regional differences. It's recommended to contact suppliers or manufacturers directly for the most accurate and up-to-date pricing information. When inquiring about prices, be sure to provide detailed specifications and requirements for the overhead crane you're interested in, as this can significantly impact the cost.

Key Features and Benefits of 20 Ton Overhead Crane:

A 20 ton overhead crane is a heavy-duty material handling equipment commonly used in industrial settings, construction sites, and manufacturing facilities. Here are some key features and benefits of a 20 ton overhead crane:

20 Ton Overhead Crane Key Features:

- Lifting Capacity: The primary feature is its substantial lifting capacity of 20 tons, making it suitable for handling heavy loads in various applications.

- Span and Coverage: Typically designed with a specific span to cover a designated area within a facility, providing versatility in material movement.

- Bridge Structure: Sturdy bridge structure ensures stability and durability, allowing the crane to handle heavy loads safely.

- Hoisting Mechanism: Equipped with a powerful hoisting mechanism, often with multiple speed options for efficient load handling.

- Trolley System: Incorporates a trolley system that moves along the bridge, allowing the crane to cover a wide area and reach different workstations.

- Control System: Modern 20 ton overhead cranes are equipped with advanced control systems, including radio remote control and precision control for accurate load positioning.

- Safety Features: Safety features such as limit switches, overload protection, emergency braking systems, and collision avoidance systems contribute to safe operations.

- Durability and Reliability: Constructed with durable materials and components to withstand the rigors of heavy-duty industrial use, ensuring long-term reliability.

20 Ton Overhead Crane Benefits:

- Increased Productivity: The high lifting capacity and efficient material handling capabilities contribute to increased productivity in various industrial processes.

- Versatility: Suitable for a wide range of applications, from manufacturing and construction to warehousing, due to its ability to handle heavy and bulky loads.

- Time and Labor Savings: Enables quick and efficient movement of materials, reducing the time and labor required for manual handling.

- Optimized Workflow: The ability to cover a large workspace and reach different workstations optimizes workflow and facilitates seamless material flow within a facility.

- Safety Assurance: Incorporation of safety features ensures a secure working environment, reducing the risk of accidents and injuries.

- Long Service Life: Designed for durability, a 20 ton overhead crane typically has a long service life with minimal maintenance requirements.

- Customization Options: Can be customized to meet specific requirements, including additional features, controls, and accessories based on the application and user preferences.

- Cost-Effective Handling: Offers a cost-effective solution for handling heavy loads compared to manual labor or alternative lifting equipment.

The Role of 20 Ton Overhead Cranes in Material Handling:

A 20 ton overhead crane plays a critical role in material handling across a range of industrial applications. Its robust design and substantial lifting capacity make it an invaluable tool for efficiently moving heavy loads. Here's a detailed look at the role of a 20 ton overhead crane in material handling:

- Heavy Load Lifting: The primary function of a 20 ton overhead crane is to lift and move heavy loads. This is particularly crucial in industries where large and dense materials need to be transported within a facility.

- Versatility: These cranes are versatile and find applications in various industries, including manufacturing, construction, shipyards, steel mills, warehouses, and more. They can handle a diverse range of materials, from machinery components to raw materials.

- Workspace Coverage: Overhead cranes are designed to cover a significant workspace. The crane's bridge travels along a runway system, and the hoisting mechanism can move the load horizontally, reaching different workstations within the facility.

- Efficiency in Material Movement: The high lifting capacity and efficient movement capabilities contribute to faster material handling processes. This results in increased overall productivity within the facility.

- Precise Load Positioning: Overhead cranes are equipped with advanced control systems that allow for precise load positioning. This is essential for placing heavy materials accurately, especially in manufacturing processes where precision is critical.

- Safety Considerations: Safety is a paramount concern in material handling. 20 ton overhead cranes come with various safety features, including overload protection, limit switches, emergency braking systems, and, in some cases, collision avoidance systems.

- Durability and Reliability: Designed for heavy-duty use, these cranes are built with durable materials and components, ensuring reliability and longevity. This makes them suitable for continuous and demanding industrial operations.

- Customization Options: Overhead cranes can be customized to suit specific material handling needs. This includes the integration of specialized lifting attachments, control systems, and other features tailored to the requirements of the particular industry or application.

- Adaptability to Various Environments: Overhead cranes can be adapted to different work environments, whether it's a manufacturing plant, warehouse, or construction site. They are designed to function seamlessly in diverse settings.

In summary, a 20 ton overhead crane is a crucial component in material handling operations, providing a reliable and efficient solution for lifting and moving heavy loads across various industrial sectors. Its impact on productivity, safety, and overall operational efficiency makes it an indispensable tool in modern manufacturing and construction processes.

Comparing 20 Ton Single Girder vs. Double Girder Overhead Crane:

When choosing between a 20 ton single girder and double girder overhead crane, several factors come into play, including the specific requirements of the application, the facility's layout, and the nature of the loads being handled. Here's a comparison between the two types of overhead cranes:

- Lifting Capacity: Both single girder and double girder overhead cranes can be designed with a 20 ton lifting capacity, so there is no inherent difference in lifting capacity between the two types.

- Clearance Height and Hook Height: Single girder cranes typically have a lower profile, offering more hook height compared to double girder cranes. This can be advantageous in facilities with limited vertical space.

- Span and Coverage: Double girder cranes generally provide a wider span and greater coverage compared to single girder cranes. If a facility requires a crane to cover a larger area, a double girder crane might be more suitable.

- Height of Lift: Double girder cranes are advantageous when a higher hook height or longer lift is required. They offer more flexibility in terms of height of lift and can be suitable for applications with varying hook heights.

- Cost Considerations: In general, single girder cranes are more cost-effective than double girder cranes. They require less material for construction and are often easier and quicker to install. If budget constraints are a significant consideration, a single girder crane may be preferred.

- Structural Design: Double girder cranes have two horizontal beams (girders) supporting the trolley, providing increased stability and rigidity. This design is advantageous for handling heavier loads and providing better resistance to deflection.

- Maintenance and Accessibility: Single girder cranes are often easier to access for maintenance due to their simpler design. Double girder cranes, with their more complex structure, may require more effort for maintenance tasks.

- Usage in Heavy-Duty Applications: Double girder cranes are generally better suited for heavy-duty applications and environments where loads are consistently at or near the crane's capacity. They provide more stability and are less prone to wear and tear in demanding conditions.

- Speed and Control: Double girder cranes may offer more precise control and higher lifting speeds compared to single girder cranes. This can be important in applications requiring careful load positioning or where faster material handling is necessary.

- Customization and Special Features: Both types of cranes can be customized to meet specific requirements. However, double girder cranes may offer more flexibility in terms of additional features and attachments due to their robust design.

In summary, the choice between a 20 ton single girder and double girder overhead crane depends on the specific needs of the application, budget constraints, and the desired features such as span, height of lift, and load handling capabilities. Each type has its advantages, and the decision should be based on a thorough assessment of the operational requirements and constraints of the facility.