15 Ton Overhead Crane

Price and Drawing of 15 Ton 25.5M European-spec Double Girder Overhead Crane for Sale to Egypt

Lifting Capacity: 15 ton

Span: 25.5 m

Lifting Height: 14.49 m

Working Class: M5

Note: We can design and manufacture the crane according your requirments and working conditions.

Price of CIF Sokhna Port of 15 Ton European-spec Double Girder Overhead Crane for Sale to Egypt:

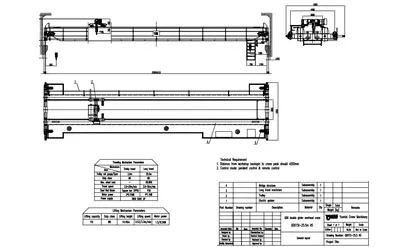

Design Drawing of 15 Ton European-spec Double Girder Overhead Crane for Sale to Egypt:

Technical Specification of 15 Ton European-spec Double Girder Overhead Crane for Sale to Egypt:

| Number | Double girder overhead crane (European type) | ||

| Lifting capacity | ton | 15 | |

| Lifting height | m | 14.49 | |

| Span | M | 25.5 | |

| Speed | Cross traveling | m/min | 2.0-20 (inverter control) |

| Crane traveling | 3.0-30 (inverter control) | ||

| Lifting speed | 0.53/3.3 (dual speed) | ||

| Working class | / | FEM 2m (ISOM5) | |

| Power supply | V/Hz/Ph | 380/50/3 | |

| Control voltage | V | 48 | |

| Cross traveling power | KW | 2*0.75 | |

| Crane traveling power | 2*1.1 | ||

| Hoisting power | 1.5/9.5 | ||

| Total power | 13.2 | ||

| Max wheel load | KN | 68.9 | |

| Total design weight | t | 16.9 | |

| Protection class | / | IP54 | |

| Insulation grade | / | F | |

| Ambient temperature | / | -10℃~+40℃ | |

| Anti-collision system | / | Included | |

| Phase protection relays | / | Included | |

| Limit switch | / | Included | |

| Voltage Low Protect device | / | Included | |

| Emergency stop action | / | Included | |

| Ground fault protection | / | Included | |

| Short-circuit protection | / | Included | |

| Over-heating protection | / | Included | |

| Power-off protection | / | Included | |

| Over-current protection | / | Included | |

| Overload protector | / | Included | |

| Top Quality Buffer | / | Included | |

| Cross Power | / | C Track Festoon Cables | |

| Country of origin | / | China | |

Recommended Crane Rail Specification of 15 ton European-spec Double Girder Overhead Crane:

| Type | Top Width(mm) | Bottom Width(mm) | Height(mm) | Weight(kg/m) |

| P30 | 60.33 | 107.95 | 107.95 | 30.1 |

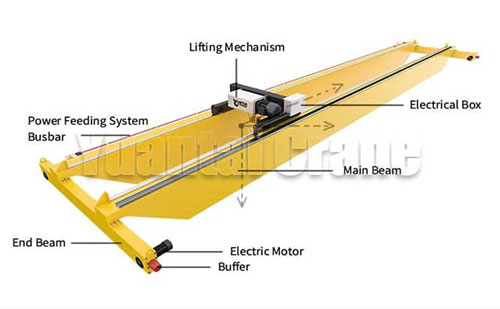

Main structure of 15 ton European-spec Double Girder Overhead Crane:

|

Main girders | Welded box-section beam, mainly use material Q235B carbon structural steel strong and elegant, easy to maintain Three-layer painting |

|

End carriages | Q235B carbon structural steel square tube torsionally rigid box section design with quality wheels and powerful 3-in-one motors Three-layer painting |

Lifting mechanism of 15 ton European-spec Double Girder Overhead Crane:

|

Low headroom hoist | High performance European standard low headroom wire rope hoist with electric trolley working class FEM 2M Insulation grade: F Protection class: IP54 |

|

Lifting motor& Travelling motor | Three-in-one motor Frequency converting control, make the lifting smooth and stable. Totally enclosed type with splash lubrication. Electromagnetic disc type brake system Insulation grade F Protection class IP54. |

|

Drum | Self-produced. Drums made of high quality steel tube processed by CNC machine. |

|

Wire rope | Rope structure 6×36SW, steel core. |

|

Rope guide | High strength nylon material, installed on the winding drum to guide the wire rope, Prevent constant winding of steel wire and prolong the life of the drum |

|

Hook | Rotating forged type with safety latch |

|

Bearing | High rotation accuracy and durability |

Crane travelling mechanism of 15 ton European-spec Double Girder Overhead Crane:

|

End carriages | Provides horizontally travelling for the crane, with quality wheels, powerful 3-in-one motors, travelling limiter and buffers |

|

Wheels | Installed on the crane end carriages, high carbon steel material. Vacuum casting by our group, Intermedium quenching by top technique machinery antirust painting, low noise |

Protection system of 15 ton European-spec Double Girder Overhead Crane:

|

Overload limiter | Under overload condition, cut off the power of the crane |

|

Rotary limit switch | For hoist travelling mechanism |

|

Buffers | Ployurethane material, used for anti-collision, equipped on the trolley and end carriages |

|

Other protection | Phase-break protection, no-voltage protection, over-current protection |

Electric parts of 15 ton European-spec Double Girder Overhead Crane:

|

Electric Cabinet | Main contactors and VFD |

|

Frequency converter | Control the travelling motors and change the motor speed. |

|

Remote control | Button: Up and down; left and right; front and back; start and stop; emergency; Dust-proof and waterproof Safe and reliable |

|

Festoon cable | Supply power for the trolley and hoist, C type cable track, safe, reliable and flexible |

Installation Specification for 15 Ton Double Girder Overhead Crane:

- Pre-Installation Preparation: Conduct a site inspection to ensure the foundation and support structures can handle the 15 ton double girder overhead crane’s load. Clear the area of debris and non-essential personnel. Verify all components of 15 ton double girder overhead crane (girders, hoist, trolley, rails, etc.) are intact and match the packing list.

- Structural Assembly: Install runway beams as per design, ensuring proper alignment and secure anchorage. Then, align and fasten girders using calibrated torque tools. Attach end 15 ton double girder overhead crane trucks firmly to the girders.

- Hoist & Trolley Installation: Mount the hoist to the trolley and test its independent movement. Attach the trolley to the girder rails, ensuring smooth travel. Install bumpers and end stops to prevent over-travel.

- Electrical & Control Wiring: Connect the power supply to the main panel using an appropriate circuit breaker. Install the control system (pendant or remote) and wire the limit switches (upper, lower, travel). Ensure proper grounding of all components. Test motor rotation and verify the emergency stop function.

- Load Testing: Perform a no-load test to check 15 ton double girder overhead crane movement. Conduct a rated load test (15-ton load) to ensure smooth operation without abnormal sounds or movements. Optionally, perform an overload test (125% of capacity) per local regulations.

Safety Operation Specification of 15 Ton Double Girder Overhead Crane:

- Pre-Operational Checks: Before each operation, thoroughly inspect all critical components, including the wire ropes, hooks, slings, brakes, and limit switches to ensure 15 ton double girder overhead crane proper functionality. Check the control panel, warning devices, and indicators for any malfunctions or issues.

- During Operation: Only certified operators should operate the 15 ton double girder overhead crane to ensure safe handling. Never lift a load over personnel to avoid accidents in case of a failure. Avoid sudden starts, stops, or direction changes as these could cause instability. When lifting loads that may swing, use tag lines to maintain control and prevent hazards. Always stay within the 15 ton double girder overhead crane’s rated load capacity of 15 tons to avoid overloading and structural strain.

- Emergency Procedures: In the event of a malfunction or failure, immediately activate the emergency stop to halt 15 ton double girder overhead crane movement and prevent further damage or injury.

- Routine Maintenance: Perform daily visual inspections of key components like hooks, ropes, and controls. On a monthly basis, inspect the electrical systems, bolts, and overhead crane’s structural integrity. Annually, schedule a thorough inspection by a certified technician to recalibrate systems if necessary and ensure the 15 ton double girder overhead crane remains in optimal working condition.

Energy-Saving Design for 15-Ton Double Girder Overhead Crane:

The energy-saving design of a 15 ton double girder overhead crane focuses on maximizing operational efficiency, reducing energy consumption, and minimizing the environmental impact without compromising the overhead crane's performance or safety. Several features contribute to making the 15 ton double girder overhead crane more energy-efficient:- Variable Frequency Drive (VFD) for Motors: Using VFDs allows the 15 ton double girder overhead crane's motors to operate at variable speeds based on the load being lifted. By adjusting motor speed, energy consumption is reduced during lighter loads or when slower speeds are sufficient. VFDs also reduce wear and tear on the motor, improving the overall lifespan of the equipment.

- High-Efficiency Motors: Equipping the 15 ton double girder overhead crane with high-efficiency motors reduces energy loss and improves power utilization. These motors are designed to minimize electrical losses, resulting in lower operational costs and reduced carbon footprint.

- Energy-Efficient Hoist Mechanism: The hoist system can be optimized with energy-saving features like lightweight materials and advanced gearing mechanisms. By reducing friction and increasing lifting efficiency, the 15 ton double girder overhead crane consumes less energy to lift and lower heavy loads.

- Smart Control Systems: Smart control systems equipped with load sensing and automatic speed control ensure that the 15 ton double girder overhead crane only uses the amount of energy necessary to complete a task. For instance, the system can adjust the lifting speed or limit the overhead crane's movement if it detects that the load does not require maximum power.

- LED Lighting: The 15 ton double girder overhead crane's lighting system can be upgraded to energy-efficient LED lights, which consume significantly less power than traditional lighting systems and have a longer lifespan.

Advantages of Energy-Saving 15 Ton Double Girder Overhead Crane:

- Reduced Operational Costs: By using energy-efficient components and systems, the 15 ton double girder overhead crane significantly reduces electricity consumption, leading to lower operating costs over time.

- Longer Equipment Lifespan: The use of high-efficiency motors, and variable speed drives reduces wear and tear on the 15 ton double girder overhead crane, extending the lifespan of key components.

- Improved Environmental Sustainability: Lower energy consumption directly translates to a reduction in the environmental footprint. The 15 ton double girder overhead crane’s energy-saving features contribute to sustainability goals by minimizing CO2 emissions.

- Enhanced Productivity: Smart control systems can optimize 15 ton double girder overhead crane operation, resulting in smoother, more efficient lifting cycles. This reduces downtime and increases the overall throughput of operations.

- Reduced Maintenance Needs: By operating with less stress on key components, such as motors and brakes, energy-efficient 15 ton double girder overhead crane typically require less frequent maintenance and repairs, leading to savings on labor and parts.

Processing of 15 Ton European-spec Double Girder Overhead Crane for Sale to Egypt:

Package and Delivery of 15 Ton European-spec Double Girder Overhead Crane for Sale to Egypt:

Product Certifications of Double Girder Overhead Crane:

Application of 15 Ton Double Girder Overhead Crane in Egypt:

Egypt’s growing focus on industrial expansion, infrastructure development, and local manufacturing has created a rising demand for efficient, heavy-duty material handling solutions. The 15 ton double girder overhead crane is becoming an essential asset across various sectors.- Industrial Zones & Manufacturing: With new industrial parks emerging in areas like 6th of October City, Sadat City, and New Alameinin Egypt, manufacturers need reliable equipment for lifting heavy components. The 15 ton double girder overhead crane is ideal for steel fabrication, machinery production, and equipment assembly, offering high precision and stable lifting over wide spans.

- Construction & Infrastructure Projects: Egypt is investing heavily in mega projects such as the New Administrative Capital and transport corridors. These projects require cranes for precast concrete, steel beams, and bridge segments—making the 15 ton double girder overhead crane a vital tool for efficient onsite and yard handling.

- Petroleum & Energy Sectors: Given Egypt's role as a key oil and gas hub and its push for renewable energy, this 15 ton double girder overhead crane type is widely used in refineries, energy plants, and equipment maintenance yards. When customized with explosion-proof or high-temperature protection, it ensures safety in hazardous or high-heat conditions.

- Ports & Logistics: As Suez Canal development and port modernization continue in Egypt, logistics hubs are turning to 15 ton double girder overhead crane for bulk cargo handling, container repair, and equipment storage.

Previous:15 Ton 20m European type Birrail Overhead Crane for Sale to Pakistan

Next: Sorry no more