Comparing Portable Gantry Crane Options: Aluminum vs. Steel

Choosing between aluminum and steel portable gantry cranes involves considering various factors such as weight, durability and intended use. Let's break down the comparison:

1. Weight:

- Aluminum: Aluminum portable gantry cranes are typically lighter than their steel counterparts. This makes them easier to transport and maneuver.

- Steel: Steel portable gantry cranes are heavier due to the denser nature of steel. While this can make them more stable for heavy lifting tasks, it also means they may require more effort to move around.

2. Durability:

- Aluminum: Aluminum is resistant to corrosion, making aluminum gantry cranes suitable for outdoor use, particularly in environments where moisture is present. However, aluminum is softer than steel and may not withstand heavy loads or harsh conditions as well.

- Steel: Steel gantry cranes are extremely durable and can handle heavier loads compared to aluminum cranes. They are less likely to deform or bend under stress, making them suitable for demanding industrial applications.

3. Portability:

- Aluminum: Due to their lighter weight, aluminum gantry cranes are more portable and easier to assemble and disassemble. They are ideal for applications where frequent relocation is required.

- Steel: Steel gantry cranes are heavier and may require more effort to transport and set up. While they are still portable to some extent, they are better suited for semi-permanent or permanent installations.

4. Load Capacity:

- Aluminum: Aluminum portable gantry cranes typically have a lower load capacity compared to steel cranes. They are suitable for light to medium-duty lifting tasks.

- Steel: Steel portable gantry cranes have a higher load capacity and can handle heavier loads with ease. They are suitable for heavy-duty industrial applications.

In summary, choosing between aluminum and steel portable gantry cranes depends on your specific requirements and priorities. If you prioritize portability, corrosion resistance, and ease of assembly, aluminum may be the better option. However, if you require higher load capacity, durability, and cost-effectiveness over the long term, steel gantry cranes may be more suitable.

Maximize Efficiency: The Benefits of Portable Gantry Cranes for Your Operations

- Space Optimization: Portable gantry cranes can be set up in tight spaces, allowing you to utilize areas that traditional cranes cannot access. Their adjustable height and width features mean they can be tailored to fit specific job requirements, maximizing your workspace.

- Cost-Effectiveness: Investing in portable gantry cranes can lead to significant cost savings. They eliminate the need for expensive fixed installations and can be moved to different locations as needed.

- Ease of Use: Most portable gantry cranes are designed for quick assembly and disassembly. Operators can set them up without specialized training, making them accessible for a variety of tasks and reducing downtime.

- Improved Safety: Portable gantry cranes enhance workplace safety by allowing for the controlled lifting and movement of heavy loads. They come equipped with safety features such as locking wheels and adjustable height options, minimizing the risk of accidents.

- Versatility: Portable gantry crane can handle various loads and materials, making them suitable for multiple applications—from construction and manufacturing to shipping and warehousing.

- Enhanced Mobility: Portable gantry cranes can be easily transported between job sites. This mobility allows businesses to respond quickly to changing needs.

- Customizable Options: Many portable gantry cranes come with customizable features, such as adjustable height, weight capacity, and attachment options, allowing you to tailor them to specific tasks and maximize their utility.

Choosing the Right Portable Gantry Crane: Key Features to Consider

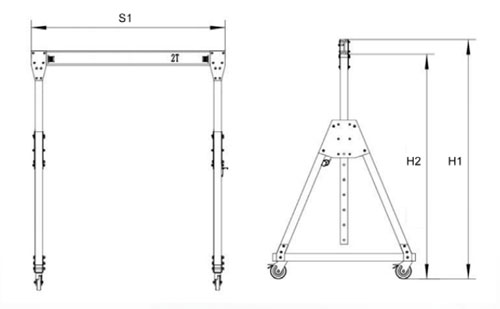

- Height and Span Adjustability: Look for portable gantry crane with adjustable height and span. This flexibility allows you to accommodate different lifting tasks and work in various environments.

- Material Construction: Consider the material of the portable gantry crane. Aluminum cranes are lightweight and portable, while steel cranes offer greater strength and durability. Your choice will depend on the balance between portability and load requirements.

- Mobility Features: Check for features like locking wheels and a lightweight design that facilitate easy movement. A portable gantry crane that can be easily transported between job sites.

- Assembly and Disassembly: Look for a portable gantry crane that is easy to assemble and disassemble. Quick setup can save valuable time and reduce downtime on projects.

- Safety Features: Ensure the portable gantry crane is equipped with safety features such as sturdy locking mechanisms, stable bases, and protective elements to prevent accidental release of loads.

- Accessories and Attachments: Consider any additional attachments or accessories that may be useful for your specific tasks, such as hoists, trolleys, or slings. Having compatible accessories can enhance the portable gantry crane's functionality.

- Environmental Considerations: If you plan to use the portable gantry crane outdoors or in harsh conditions, ensure it is weather-resistant or designed for those environments. Corrosion-resistant materials can extend the lifespan of the equipment.

Portable Gantry Cranes vs. Traditional Cranes: Which is Right for You?

The choice of portable gantry cranes versus conventional cranes depends primarily on specific needs, including flexibility, load capacity, cost, space requirements and safety. Portable gantry cranes are highly mobile, suitable for light loads, have low investment costs and are suitable for small construction and maintenance tasks. Conventional cranes, on the other hand, are suitable for heavy loads and large projects with high load capacity, but are costly and take up a lot of space. Choose the most suitable type of crane based on your operational needs, space availability and budget.

Maintenance Tips for Extending the Life of Your Portable Gantry Crane:

- Daily Checks: Inspect the portable gantry crane before each use, looking for signs of wear, damage, or rust. Pay attention to the frame, wheels, and any moving parts.

- Remove Debris: Regularly clean the portable gantry crane to prevent the buildup of dirt, grease, and other debris, especially in joints and moving parts.

- Apply Lubricant: Regularly lubricate all moving parts, including wheels and joints, to ensure smooth operation and prevent wear.

- Adhere to Capacity Limits: Always check and respect the load capacity of the portable gantry crane to prevent overloading, which can lead to structural damage.

- Dry, Protected Area: Store the portable gantry crane in a dry, sheltered location to protect it from environmental factors like moisture, which can lead to rust.

- Check Hoists and Slings: Regularly inspect any attached hoists, slings, or rigging equipment for signs of wear or damage.

Application of Portable Gantry Cranes in Various Industries:

Manufacturing

Assembly Lines: Portable gantry crane ideal for lifting and positioning heavy components during assembly processes in confined spaces.

Maintenance Tasks: Facilitates the movement of machinery and parts for repairs, allowing for quick setup and flexibility.

Construction

Material Handling: Portable gantry crane used to lift and transport heavy building materials on job sites, particularly in areas where traditional cranes can’t operate.

Installation of Pre-Fabricated Parts: Efficiently lifts and places pre-fabricated components, such as panels or beams.

Automotive

Engine and Component Lifting: Portable gantry crane useful for lifting engines and other heavy parts during repair and maintenance tasks in garages or workshops.

Assembly Support: Assists in the assembly and disassembly of vehicles, providing a stable lifting solution.

Warehousing and Logistics

Loading and Unloading: Aids in efficiently loading and unloading heavy items from trucks or containers, enhancing productivity.

Inventory Management: Moves heavy stock within warehouses, optimizing space and workflow.

Energy Sector

Wind Turbine Maintenance: Portable gantry crane useful for lifting components during maintenance of wind turbines, often in remote locations.

Power Plant Operations: Aids in moving heavy equipment and parts in power generation facilities, enhancing safety and efficiency.

Research and Development

Laboratory Equipment Handling: Portable gantry crane ideal for lifting and moving heavy scientific equipment in research settings, allowing for flexible workspace arrangements.

Testing Facilities: Assists in positioning equipment for testing and development projects, particularly where space is limited.