A 1 ton electric hoist is a versatile and efficient lifting device designed to handle loads up to 1 ton with ease and precision. This 1 ton electric hoist is equipped with a robust motor and durable hoisting mechanism, making it ideal for a wide range of lifting applications in industries such as manufacturing, construction, warehousing, and more. With its compact size and powerful lifting capacity, the 1 Ton Electric Hoist offers convenience, safety, and reliability in lifting and moving heavy objects. Whether used in workshops, garages, or industrial settings, 1 ton electric hoist is a valuable tool for improving productivity and streamlining lifting operations.

Different Types of 1 Ton Electric Chain Hoist Specification for Sale:

1 Ton Motorized Trolley Electric Chain Hoist for Sale

1 Ton Motorized Trolley Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Hook type Electric Chain Hoist for Sale

1 Ton Hook type Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Low Headroom Electric Chain Hoist for Sale

1 Ton Low Headroom Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 3-130 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Manual Trolley Electric Chain Hoist for Sale

1 Ton Manual Trolley Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton European Electric Chain Hoist for Sale

1 Ton European Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 1 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Manual Chain Hoist for Sale

1 Ton Manual Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 0.5~3.5m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Double Hook Electric Chain Hoist for Sale

1 Ton Double Hook Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height:According your demands

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Explosion-proof Electric Chain Hoist for Sale

1 Ton Explosion-proof Electric Chain Hoist for SaleCapacity: 1 Ton

Lifting height: 3/6/9/12/18 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Top Features of the 1 Ton Electric Chain Hoist for Industrial Use:

- Fast Lifting Speed: 1 ton electric chain hoist designed for quick operation, reducing downtime and increasing productivity.

- Durable Construction: 1 ton electric chain hoist made from high-quality materials to withstand harsh industrial environments and ensure long-term reliability.

- Safety Features: Equipped with overload protection, emergency stop functions, and automatic braking systems to ensure safe lifting.

- Compact Design: Space-saving construction allows for easy installation and maneuverability in tight spaces.

- Versatile Applications: 1 ton electric chain hoist suitable for various industrial tasks, including construction, warehousing, and manufacturing.

- Low Maintenance Requirements: Designed for easy maintenance, reducing operational costs and downtime.

- Remote Operation: Some models of 1 ton electric chain hoist offer remote controls for added convenience and safety during operation.

How to Choose the Right 1 Ton Electric Chain Hoist for Your Needs:

- Lifting Height: Assess the required lifting height. Ensure the 1 ton electric chain hoist’s lift distance meets your specific needs for both operational efficiency and safety.

- Speed of Lifting: Consider the speed at which you need to lift and lower loads. Faster lifting speeds can enhance productivity, but ensure it suits your operational requirements.

- Control Type: Look for user-friendly controls. Options include pendant controls, remote controls, or even wireless options for added convenience.

- Safety Features: Ensure the 1 ton electric chain hoist includes essential safety features, such as overload protection, emergency stop functions, and automatic braking systems.

- Environmental Considerations: Consider the operating environment. If the 1 ton electric chain hoist will be used in harsh conditions (e.g., extreme temperatures, exposure to dust or moisture), look for models with appropriate ratings (e.g., IP ratings).

- Chain Length and Type: Evaluate the type of chain and its length. Some applications may require longer chains or specific materials for durability.

- Budget: Set a budget while considering the features you need. Balance between quality and cost to find the best 1 ton electric chain hoist for your requirements.

- Additional Features: Consider any additional features that may be beneficial, such as adjustable lifting speeds, built-in lights, or automatic limit switches.

Comparing Manual vs. Electric Chain Hoists:

When deciding between manual and electric 1 ton chain hoists, it's important to weigh the pros and cons of each type based on your specific needs. Here’s a comparison to help you choose the best option for your applications:

1. Lifting Capacity and Speed

Electric Chain Hoists: Speed: Generally faster lifting and lowering of loads, ideal for high-frequency tasks.

Capacity: Suitable for heavier loads and continuous operation without fatigue.

Manual Chain Hoists: Speed: Slower operation, requiring more physical effort to lift loads.

Capacity: Can lift the same weight, but may not be as efficient for frequent or heavy lifting.

2. Portability and Setup

Electric Chain Hoists: Weight: Often heavier due to motor components, but some models are designed for portability.

Setup: May require more time for installation and setup due to electrical connections.

Manual Chain Hoists: Lightweight: Typically easier to transport and set up, making them ideal for mobile applications.

No Power Source Needed: Can be used in areas without electricity, making them versatile for various job sites.

3. Safety Features

Electric Chain Hoists: Advanced Safety: Usually equipped with safety features like overload protection, automatic brakes, and limit switches.

Manual Chain Hoists: Basic Safety: Safety depends on the operator’s knowledge and skill. Fewer built-in safety features.

4. Maintenance and Longevity

Electric Chain Hoists: Maintenance Needs: Require more maintenance due to electrical components but are generally durable.

Manual Chain Hoists: Lower Maintenance: Simpler design often leads to lower maintenance needs and longer life if properly cared for.

Choose Electric Chain Hoists: if you need speed, efficiency, and advanced safety features for frequent lifting tasks in an industrial setting.

Choose Manual Chain Hoists: if portability, simplicity, and lower costs are your priorities, particularly for occasional use or in areas without electrical access. Assess your specific lifting needs, work environment, and budget to determine the best option for you!

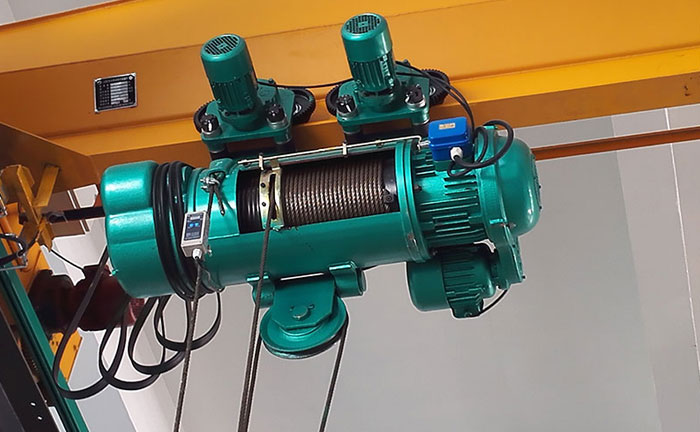

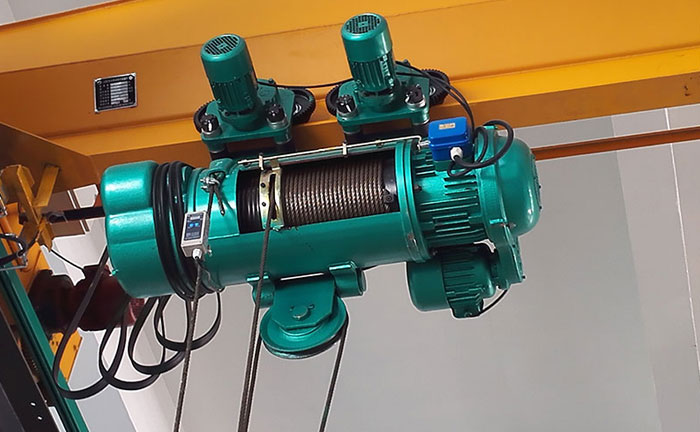

Different Types of 1 Ton Electric Wire Rope Hoist Specification for Sale:

1 Ton Single Speed Electric Wire Rope Hoist for Sale

1 Ton Single Speed Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Double Speed Electric Wire Rope Hoist for Sale

1 Ton Double Speed Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Low Headroom Electric Wire Rope Hoist for Sale

1 Ton Low Headroom Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 3~60m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Explosion-proof Electric Wire Rope Hoist for Sale

1 Ton Explosion-proof Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 3~100m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Metallurgical Electric Wire Rope Hoist for Sale

1 Ton Metallurgical Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 6~18m

Working Duty:M3

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale

1 Ton European standard Low Headroom Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 6m-50m

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale

1 Ton Single & Double Girder European Style Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height:1-120M

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Mini Electric Wire Rope Hoist for Sale

1 Ton Mini Electric Wire Rope Hoist for SaleCapacity: 1 ton

Lifting height: 3-24m

Working Duty:M3

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

1 Ton Double Hook Electric Wire Rope Hoist for Sale

1 Ton Double Hook Electric Wire Rope Hoist for SaleCapacity: 1 Ton

Lifting height: 6-100m

Working Duty:M3, M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

The Benefits of 1 Ton Electric Wire Rope Hoist:

A 1 ton electric wire rope hoist offers numerous benefits in various industrial and construction settings. Here are some key advantages:

- High Efficiency: 1 ton electric wire rope hoist are designed for quick lifting and lowering of loads, which increases productivity in work environments.

- Ease of Use: With user-friendly controls, 1 ton electric wire rope hoist are easier to operate compared to manual hoists, reducing the risk of operator fatigue.

- Safety Features: Many 1 ton electric wire rope hoist come equipped with safety features such as overload protection, emergency stop buttons, and limit switches to prevent accidents.

- Durability: Built with robust materials, 1 ton electric wire rope hoist are designed to withstand heavy use and harsh environments, ensuring long-term reliability.

- Versatility: A 1 ton capacity makes 1 ton electric wire rope hoist suitable for various applications, including construction, manufacturing, and warehouses.

- Space Efficiency: 1 ton electric wire rope hoist can be mounted on different structures (like beams or ceilings), saving valuable floor space.

- Smooth Operation: Electric hoists provide smooth and controlled lifting and lowering, which is particularly important for delicate loads.

- Maintenance Accessibility: Most 1 ton electric wire rope hoist are designed for easy maintenance, ensuring they remain in good working condition with minimal downtime.

How to Operate a 1 Ton Electric Wire Rope Hoist Safely:

- Pre-Operation Inspection: Inspect the 1 ton electric wire rope hoist, hooks, and wire rope for any signs of wear, damage, or corrosion; Test the controls to ensure they are functioning properly before lifting any load.

- Proper Rigging Techniques: Use appropriate rigging equipment (slings, hooks, etc.) that is rated for the load; Securely attach the load to avoid slippage during lifting.

- Lift Operations: Operate the 1 ton electric wire rope hoist at a steady speed to prevent sudden movements; Ensure the load is evenly balanced before lifting.

- Avoid Swinging Loads: Keep the load as stable as possible to avoid swinging, which can lead to loss of control; Move the load in a straight line whenever possible.

- Load Placement: Position the load securely and ensure it is stable before disconnecting the 1 ton electric wire rope hoist; Lower the load gently and avoid dropping it.

- Regular Maintenance: Schedule regular maintenance checks to keep the 1 ton electric wire rope hoist in optimal condition; Lubricate moving parts and replace worn components as needed.

- Emergency Procedures: Familiarize operators with emergency shutdown procedures; Ensure easy access to emergency stop buttons.

By following these guidelines, you can operate a 1 ton electric wire rope hoist safely while maximizing efficiency. Regular training, proper maintenance, and clear communication are key to ensuring a safe and effective lifting environment.

Types of 1 ton electric hoist price:

1 ton electric chain hoist price & specification:

- Lifting capacity: 1t

- Lifting height: 3 ~ 120m

- Working class: M3, M4

- Ambient temperature: -20 ~ 40

- Price(USD): $500 to $3,000

Features:

- Uses a chain to lift heavy loads

- More compact, lightweight than wire rope hoist

- Is easier to maintain and repair than a wire rope hoist

Read More Inquire Now

1 Ton electric wire rope hoist price & specification:

- Lifting capacity (T): 1t

- Lifting height: 6 ~ 100m

- Working class: M3, M4

- Ambient temperature: -20 ~ 40

- Price(USD): $800 to $4,000

Features:

- Uses a wire rope to lift heavy loads

- Can lift heavier loads than a chain hoist

- Offers a smoother lifting experience due to the wire rope's flexibility

Read More Inquire Now

Comparison of 1 ton electric wire rope hoist and 1 ton electric chain hoist:

When choosing between a 1 ton Electric Wire Rope Hoist and a 1 ton Electric Chain Hoist, by considering these factors, you can determine which type of hoist is best suited for your specific lifting needs.

- Load weight: Electric Wire Rope Hoists can lift heavier loads than Electric Chain Hoists.

- Lifting height: Wire rope hoists can lift to greater heights than chain hoists. If you need to lift loads to a great height, then a wire rope hoist may be the better choice.

- Frequency of use: If you need to lift loads frequently, then an electric chain hoist may be the better choice as it is easier to maintain and repair.

- Cost: Electric Chain Hoists are less expensive than Electric Wire Rope Hoists. If cost is a major concern, then a chain hoist may be the better choice.

1 ton electric hoist price:

The 1 ton electric hoist price can vary depending on the brand, model, and features of the hoist. Typically, basic 1 ton electric hoist price range is between $500 to $3500 USD. However, the price can increase significantly if additional features are added, such as a wireless remote control, higher lifting height, or specialized attachments.

1 ton Electric Wire Rope Hoist with Trolley Price

- lifting capacity: 1 ton

- lifting height: 1-100m

- Price: $400-$3500

1 ton European-spec Electric Hoist Price

- lifting capacity: 1 ton

- lifting height: 1-50m

- Price: $1500-$3500

1 ton Electric Chain Hoist with Motorized Trolley Price

- lifting capacity: 1 ton

- lifting height: 1-30m

- Price: $550-$3000

1 ton Electric Chain Hoist with Manual Trolley Price

- lifting capacity: 1 ton

- lifting height: 1-30m

- Price: $550-$3000

1 ton Hook type Electric Chain Hoist Price

- lifting capacity: 1 ton

- lifting height: 1-30m

- Price: $500-$2000

NRF type 1 ton Electric Wire Rope Hoist Price

- lifting capacity: 1 ton

- lifting height: 1m-50m

- Price: $800-$3000

The 1 ton electric hoist price is just one factor to consider when making a purchase. Other factors to consider include the quality and reliability of the hoist, as well as the level of customer support and after-sales service provided by the manufacturer or vendor.

Applications of 1 Ton Electric Hoist in various industries:

A 1 ton electric hoist is a versatile piece of equipment used across various industries for lifting and moving heavy loads. Here are some specific applications in different sectors:

1. ManufacturingAssembly Lines: Moving components and finished products along assembly lines.

Machine Maintenance: Lifting heavy machinery for repairs and maintenance.

2. Warehousing and DistributionLoading and Unloading: Assisting in loading pallets and boxes onto trucks or shelves.

Stock Management: Helping organize inventory by moving heavy items to designated storage areas.

3. AutomotiveVehicle Repair: Lifting engines, transmissions, and other heavy parts for repair and replacement.

Assembly Operations: Assisting in the assembly of vehicles and parts.

4. MiningEquipment Maintenance: Lifting heavy mining equipment for maintenance or replacement.

Material Handling: Moving mined materials to processing areas.

5. AerospaceAircraft Maintenance: Lifting aircraft components for inspection and repairs.

Assembly Lines: Assisting in the assembly of aircraft parts.

6. AgricultureFarm Equipment: Lifting and moving heavy agricultural machinery or supplies.

Livestock Management: Assisting in the handling of heavy feed and supplies.

1 Ton Motorized Trolley Electric Chain Hoist for Sale

1 Ton Motorized Trolley Electric Chain Hoist for Sale 1 Ton Hook type Electric Chain Hoist for Sale

1 Ton Hook type Electric Chain Hoist for Sale 1 Ton Low Headroom Electric Chain Hoist for Sale

1 Ton Low Headroom Electric Chain Hoist for Sale 1 Ton Manual Trolley Electric Chain Hoist for Sale

1 Ton Manual Trolley Electric Chain Hoist for Sale 1 Ton European Electric Chain Hoist for Sale

1 Ton European Electric Chain Hoist for Sale 1 Ton Manual Chain Hoist for Sale

1 Ton Manual Chain Hoist for Sale 1 Ton Double Hook Electric Chain Hoist for Sale

1 Ton Double Hook Electric Chain Hoist for Sale 1 Ton Explosion-proof Electric Chain Hoist for Sale

1 Ton Explosion-proof Electric Chain Hoist for Sale 1 Ton Single Speed Electric Wire Rope Hoist for Sale

1 Ton Single Speed Electric Wire Rope Hoist for Sale 1 Ton Double Speed Electric Wire Rope Hoist for Sale

1 Ton Double Speed Electric Wire Rope Hoist for Sale 1 Ton Low Headroom Electric Wire Rope Hoist for Sale

1 Ton Low Headroom Electric Wire Rope Hoist for Sale 1 Ton Explosion-proof Electric Wire Rope Hoist for Sale

1 Ton Explosion-proof Electric Wire Rope Hoist for Sale 1 Ton Metallurgical Electric Wire Rope Hoist for Sale

1 Ton Metallurgical Electric Wire Rope Hoist for Sale 1 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale

1 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale 1 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale

1 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale 1 Ton Mini Electric Wire Rope Hoist for Sale

1 Ton Mini Electric Wire Rope Hoist for Sale 1 Ton Double Hook Electric Wire Rope Hoist for Sale

1 Ton Double Hook Electric Wire Rope Hoist for Sale