Choosing the Right 2 Ton Overhead Crane for Your Facility:

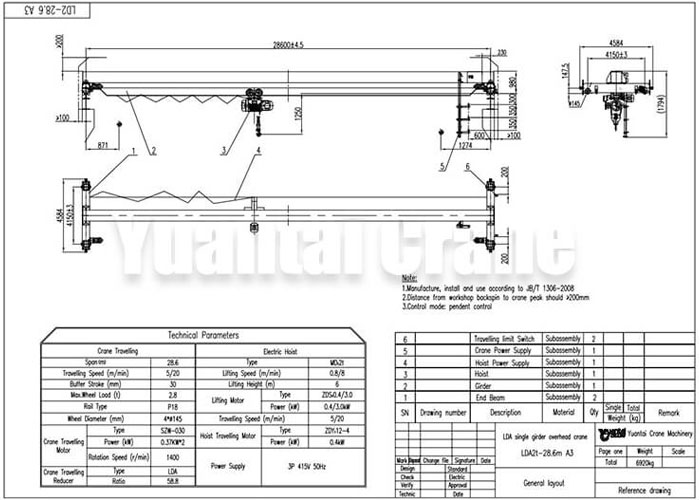

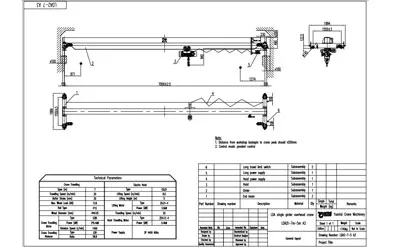

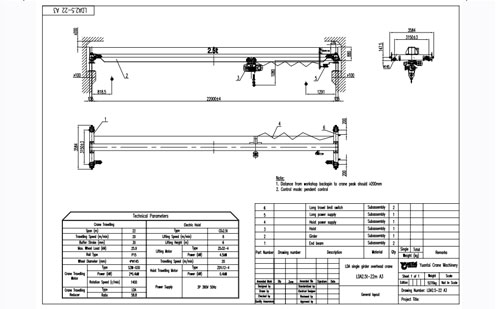

- Lift Height: Assess the maximum height required for your operations. Ensure the overhead crane can lift loads to the necessary height without limitations.

- Span and Coverage Area: Determine the width of your workspace. Choose a 2 ton overhead crane that can cover the required area efficiently.

- Control Options: Manual vs. Electric: Electric controls can improve precision and reduce labor fatigue. Remote Control: Consider for safety and convenience, especially in complex layouts.

- Load Types and Rigging: Identify the types of loads you'll be lifting. Ensure the 2 ton overhead crane can accommodate rigging and attachments needed for specific items.

- Frequency of Use: Evaluate how often the overhead crane will be used. More frequent use may necessitate a more robust and durable model.

- Environment: Consider factors like temperature, humidity, and the presence of dust or corrosive materials. Choose a 2 ton overhead crane designed for those specific conditions.

- Safety Features: Look for overhead crane with features like overload protection, emergency stops, and limit switches to enhance safety.

- Budget and Cost of Ownership: Factor in not just the purchase price, but also the operational costs, maintenance, and potential downtime.

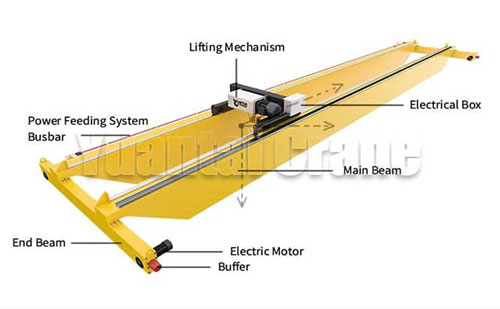

Key Features of 2 Ton Overhead Crane:

- Span and Reach: Available in various spans to accommodate different workspace layouts. The reach allows for maneuverability over wide areas.

- Control Systems: May include pendant controls, remote controls, or wireless options for ease of operation and safety.

- Construction Materials: Made from durable materials like steel to ensure strength and longevity, often featuring corrosion-resistant coatings.

- Mobility Options: Some overhead crane may be fixed, while others are designed to be mobile with wheels or tracks for versatile positioning.

- Trolley System: Allows horizontal movement of the load along the beam, enhancing operational efficiency.

- Installation Options: Can be ceiling-mounted, supported by columns, or freestanding depending on the facility's layout.

- Customization: Many models offer customization options, such as different hoist types, control systems, and additional safety features.

The Benefits of Investing in a 2 Ton Overhead Crane:

1. Increased Efficiency

Streamlined Operations: 2 ton overhead crane can lift and move heavy loads quickly and safely, reducing downtime and increasing productivity.

Space Utilization: 2 ton overhead crane operate overhead, freeing up floor space for other activities, which can lead to better organization and workflow.

2. Enhanced Safety

Reduced Risk of Injury: By mechanizing lifting tasks, 2 ton overhead crane minimize the risk of injuries associated with manual lifting.

Safety Features: Modern overhead crane are equipped with safety systems, such as overload protection and limit switches, ensuring safer operations.

3. Durability and Longevity

Robust Construction: Built from durable materials, 2 ton overhead crane are designed for heavy-duty use, leading to lower maintenance costs over time.

Long-Term Investment: A quality overhead crane can last for years, providing a solid return on investment.

4. Versatility

Multi-Functional Use: Suitable for various applications, from manufacturing to warehousing, making them a flexible investment.

Customization Options: Can be tailored to specific operational needs, ensuring that you get the best fit for your business.

5. Improved Load Management

Precision Handling: 2 ton overhead crane allow for precise placement of loads, reducing the likelihood of damage to materials and equipment.

Enhanced Control: Operators can move loads in multiple directions, allowing for better handling of heavy items.

Installation and Maintenance Tips for 2 Ton Overhead Crane:

Installation Tips

- Site Assessment: Ensure the installation site is clear and structurally sound, with adequate support for the overhead crane's weight and load capacity.

- Proper Alignment: Follow manufacturer guidelines for aligning tracks and supports to ensure smooth operation.

- Professional Help: Consider hiring certified professionals for installation to guarantee compliance with safety standards.

- Electrical Connections: Ensure all electrical components are properly installed and grounded to prevent hazards.

- Testing Before Use: Conduct a thorough test run after installation to verify all systems are functioning correctly.

Maintenance Tips

- Regular Inspections: Schedule routine inspections to check for wear and tear on components, including hooks, cables, and pulleys.

- Lubrication: Keep moving parts well-lubricated to reduce friction and extend the 2 ton overhead crane’s lifespan.

- Load Testing: Periodically perform load tests to ensure the 2 ton overhead crane can handle its rated capacity safely.

- Cleanliness: Keep the 2 ton overhead crane and surrounding area clean to prevent debris from interfering with operations.

- Document Maintenance: Maintain records of inspections and repairs to track the overhead crane's condition over time.

Real-World Applications of 2-Ton Overhead Cranes Across Industries:

1. Manufacturing Material Handling: 2 ton overhead crane used for lifting heavy components, machinery parts, and tools, streamlining production processes.

Assembly Lines: Facilitate the assembly of large products by moving components into position with precision.

2. Construction Steel Erection: Assist in lifting and positioning steel beams and other heavy materials during building construction.

Site Maintenance: 2 ton overhead crane useful for moving heavy equipment and materials on construction sites, enhancing efficiency.

3. Warehousing Inventory Management: Employed for loading and unloading pallets, boxes, and heavy goods, improving storage operations.

Order Fulfillment: Help in quickly accessing and relocating items to fulfill orders efficiently.

4. Automotive Industry Parts Handling: 2 ton overhead crane ideal for lifting and moving engine components, frames, and other heavy parts in assembly plants.

Maintenance and Repair: 2 ton overhead crane used in service areas to hoist vehicles for inspection and repairs.

5. Shipbuilding and Repair Heavy Lifting: Crucial for moving large sections of ships during construction or repair processes.

Maintenance Operations: Assist in hoisting equipment and materials needed for ongoing maintenance tasks.

6. Metal Fabrication Handling Raw Materials: 2 ton overhead crane used to lift and position heavy metal sheets, pipes, and blocks for fabrication processes.

Assembly Support: 2 ton overhead crane facilitate the assembly of metal structures and products by providing efficient load movement.

7. Aerospace Component Assembly: Assist in lifting and positioning large aircraft components during assembly and maintenance.

Material Handling: Used for moving heavy equipment and materials in aerospace manufacturing facilities.

8. Power Generation Turbine Assembly: Employed in the assembly and maintenance of turbines and other heavy equipment in power plants.

Equipment Installation: Facilitate the installation of heavy machinery and components in generating facilities.

9. Recycling and Waste Management Material Handling: Used to lift and transport heavy loads of recyclable materials or waste products within processing facilities.

Sorting Operations: Assist in moving materials to different sorting stations for efficient processing.