Choosing the Right 5 Ton Gantry Crane for Your Needs:

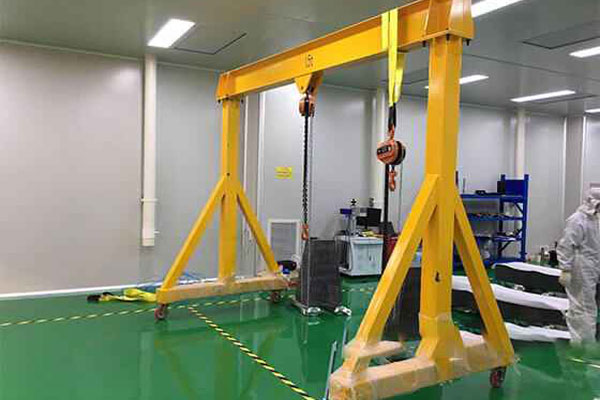

- Load Capacity: Confirm that the 5 ton gantry crane can handle your maximum load of 5 tons comfortably.

- Height and Span Adjustability: Look for models with adjustable height and span to accommodate different workspaces and lifting needs.

- Material and Construction: Durable materials, such as steel or aluminum, enhance strength and longevity. Check for corrosion resistance if used outdoors.

- Mobility: Consider whether you need fixed or mobile options. Models with wheels or casters allow for easier maneuverability.

- Assembly and Disassembly: Look for 5 ton gantry crane that are easy to assemble and disassemble for storage and transport.

- Safety Features: Safety locks, limit switches, and emergency stop buttons are crucial for preventing accidents.

- Ease of Operation: A user-friendly design with smooth rolling wheels and ergonomic controls makes operation easier.

5 Ton Gantry Cranes: Safety Tips for Operation and Maintenance

Operation Safety Tips:

- Conduct Pre-Operation Inspections: Always check for signs of wear, damage, or loose connections before use.

- Use Proper Signage: Clearly mark the area around the 5 ton gantry crane to keep unauthorized personnel at a safe distance.

- Load Limits: Never exceed the 5 ton capacity and ensure loads are evenly distributed.

- Clear Communication: Use hand signals or radios for clear communication between operators and ground personnel.

- Stabilize Loads: Secure loads properly to prevent shifting during lifting or movement.

- Stay Within Vision: Always keep the load in sight while lifting and moving.

Maintenance Safety Tips:

- Regular Inspections: Schedule routine inspections for critical components, including hoists and wheels.

- Lubrication: Keep moving parts lubricated to reduce friction and wear.

- Cleaning: Regularly clean the 5 ton gantry crane to remove debris and contaminants that could affect operation.

- Documentation: Maintain a log of inspections, repairs, and any incidents to track the gantry crane's condition.

- Training: Ensure all operators are properly trained in 5 ton gantry crane operation and safety procedures.

The Benefits of Investing in a 5 Ton Gantry Crane for Your Facility:

- Increased Efficiency: Streamlines lifting and moving heavy loads, reducing manual labor and time spent on tasks.

- Versatility: Suitable for various applications, from manufacturing to construction, accommodating different types of loads.

- Space Optimization: Can be configured for tight spaces, especially with adjustable height and span options.

- Improved Safety: Reduces the risk of injuries associated with manual lifting and improves overall workplace safety.

- Cost-Effectiveness: Minimizes labor costs and potential damage to goods, leading to better resource allocation.

- Durability: Built to withstand heavy use, providing a long-term solution for lifting needs.

- Mobility Options: Many models are portable, allowing for easy relocation within your facility.

Cost Analysis: Understanding the Investment in a 5 Ton Gantry Crane

1. Initial Purchase CostsCrane Price: The price of a 5 ton gantry crane can vary widely based on brand, features, and specifications. Expect costs to range from $5,000 to $20,000.

Accessories: Additional costs may include hoists, slings, and other lifting accessories.

2. Operational CostsPower Consumption: Consider the electricity costs if the 5 ton gantry crane is electrically powered.

Labor Costs: Factor in the salaries of operators and any additional training required.

Insurance: Coverage for equipment and liability must be accounted for.

3. Maintenance CostsRoutine Maintenance: Regular inspections and servicing are necessary for safety and longevity. This could include lubrication, checking for wear, and replacing parts.

Unexpected Repairs: Setting aside a budget for unforeseen repairs or replacements is prudent.

4. Return on Investment (ROI)Increased Efficiency: Calculate how the 5 ton gantry crane will improve workflow and reduce labor costs.

Revenue Generation: If the gantry crane is used in a revenue-generating capacity (e.g., in a manufacturing or construction setting), estimate the additional revenue it can create.

In summary, the investment in a 5 ton gantry crane involves various costs, from initial purchase to ongoing operational and maintenance expenses. A comprehensive cost analysis not only helps in understanding the total investment but also aids in making informed decisions about whether the 5 ton gantry crane aligns with business goals and operational needs.

The Importance of Regular Maintenance for Your 5 Ton Gantry Crane:

- Safety: Routine checks help identify wear and tear, reducing the risk of accidents or failures during operation.

- Operational Efficiency: Regular maintenance ensures that all components, such as hoists and trolleys, function smoothly, enhancing productivity.

- Longevity: Keeping your 5 ton gantry crane in good condition can extend its lifespan, protecting your investment.

- Cost Savings: Preventative maintenance can reduce the likelihood of costly repairs or unexpected downtime.

Applications of 5 Ton Gantry Crane in Various Industries

ManufacturingAssembly Lines: Moving heavy parts and assemblies during production.

Quality Control: 5 ton gantry crane lifting and inspecting large components for defects.

ConstructionMaterial Handling: Lifting and placing beams, steel, and concrete blocks.

Equipment Relocation: Moving heavy machinery and tools around job sites.

Shipping and LogisticsLoading/Unloading: Handling containers and pallets in warehouses and docks.

Transport: Moving goods between different areas of a facility.

AutomotiveMaintenance and Repair: 5 ton gantry crane lifting vehicles for servicing and parts replacement.

Assembly: Assisting in the assembly of large automotive components.

AerospaceComponent Assembly: Handling large aerospace parts during manufacturing.

Maintenance: Assisting in repairs and inspections of aircraft.

Mining and Heavy IndustryEquipment Maintenance: Lifting and moving heavy mining equipment.

Material Handling: Managing raw materials and components.

Energy SectorWind Turbine Installation: Lifting components for wind turbines.

Plant Maintenance: Facilitating repairs and maintenance in power plants.

Rail and TransportationRailcar Maintenance: 5 ton gantry crane lifting and inspecting railway cars and components.

Parts Handling: Moving heavy parts in rail manufacturing facilities.

Metal FabricationHeavy Lifting: Handling sheets and heavy metal components.

Welding and Assembly: Assisting in the assembly of large metal structures.