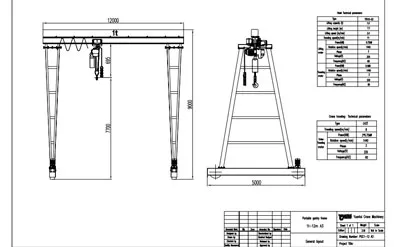

1 Ton Portable Gantry Crane Total width 12M for Sale to Columbia

1 Ton Portable Gantry Crane Total width 12M for Sale to Columbia

Capacity: 1 ton

Lifting height: 9m

Span: 12m

Power supply: 220V /60HZ /3 Phase

Control: Pendant control

Working class: A3