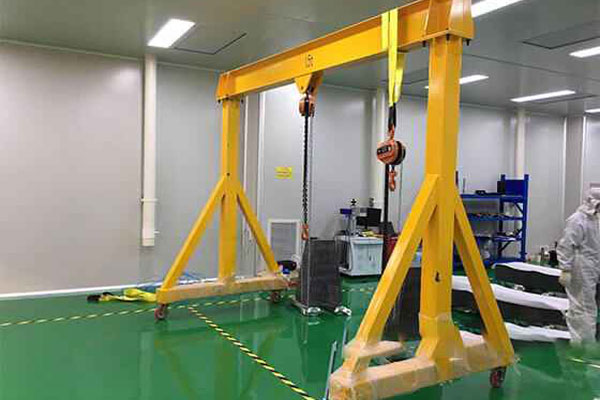

1 Ton Gantry Crane

1 ton gantry crane is designed to handle loads with a maximum weight capacity of 1 ton. 1 ton gantry crane are commonly used in warehouses, workshops, construction sites, and other industrial applications where materials or products need to be moved or lifted.