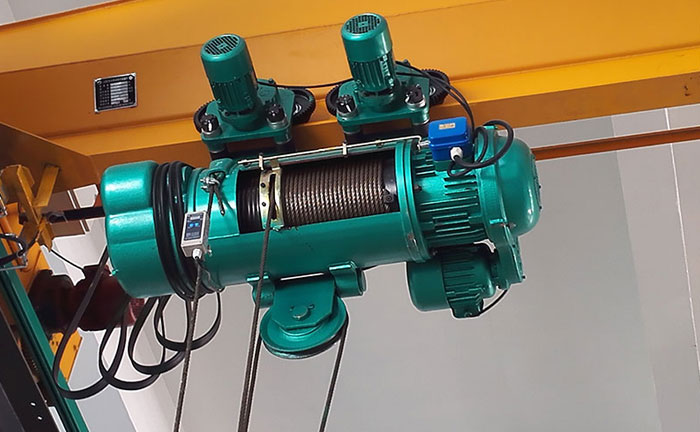

Electric Wire Rope Hoist

Electric Wire Rope Hoist Specification:

- Lifting Capacity: 0.25t-63 ton

- Lifting Height: 1m-100m

- Lifting Speed: 3.5/0.35—8/0.8 m/min

- Working Class: M3、M4

- Temperature: -25℃~+40℃

- Power Supply: 3 phase,200~600V,50/60HZ

We can design and manufacture non-standard products according to your needs.

Different Types of Electric Wire Rope Hoist Specification for Sale:

Single Speed Electric Wire Rope Hoist

Single Speed Electric Wire Rope HoistLifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Double Speed Electric Wire Rope Hoist

Double Speed Electric Wire Rope HoistLifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Low Headroom Electric Wire Rope Hoist

Low Headroom Electric Wire Rope HoistCapacity: 0.5~32 ton

Lifting height: 3~60m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Explosion-proof Electric Wire Rope Hoist

Explosion-proof Electric Wire Rope HoistCapacity: 0.5~50 ton

Lifting height: 3~100m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Metallurgical Electric Wire Rope Hoist

Metallurgical Electric Wire Rope HoistCapacity: 1~20 ton

Lifting height: 6~18m

Working Duty:M3

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

European standard Low Headroom Electric Wire Rope Hoist

European standard Low Headroom Electric Wire Rope HoistCapacity: 1~80 ton

Lifting height: 6m-50m

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Single & Double Girder European Style Electric Wire Rope Hoist

Single & Double Girder European Style Electric Wire Rope HoistCapacity: 1-80 ton

Lifting height:1-120M

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Mini Electric Wire Rope Hoist

Mini Electric Wire Rope HoistCapacity: 0.2-1 ton

Lifting height: 3-24m

Working Duty:M3

Ambient Temperature: -25~40℃

Double Hook Electric Wire Rope Hoist

Double Hook Electric Wire Rope HoistCapacity: 0.5-32 ton

Lifting height: 6-100m

Working Duty:M3, M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Technical Data of Electric Wire Rope Hoist:

| Model | CD1 MD1 | |||||||||

| Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

| Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

| Hoisting speed | M/MIN | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) | 3.5 (0.35/3.5) | ||||

| Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

| Wirerope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

| Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

| Hoisting motor | Type | Type | ZD112-4 | ZD1 21-4 | ZD1 22-4 | ZD1 31-4 | ZD1 32-4 | ZD1 41-4 | ZD1 51-4 | ZD1 51-4 |

| ZDS1 0.2/0.8 | ZDS1 0.2/1.5 | ZDS1 0.4/3.0 | ZDS1 0.4/4.5 | ZDS1 0.8/7.5 | ZDS1 1.5/13 | ZDS1 1.5/13 | ||||

| Power | Power(kW) | 0.4 | 0.8(0.2/0.8) | 1.5 (0.2/1.5) | 3.0 (0.4/3.0) | 4.5 (0.4/4.5) | 7.5(0.8/7.5) | 13 (1.5/13) | 13(1.5/13) | |

| Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

| Current | (A) | 1.25 | 2.2 (0.72/2.4) | 4.3 (0.72/4.3) | 7.6(1.25/7.6) | 11(2.4/11) | 18 (2.4/18) | 30 (5.2/30) | 30(5.2/30) | |

| Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

| Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

| Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

| Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

| Power | 220~440V 50/60HZ 3Phase | |||||||||

Different Tons of Electric Wire Rope Hoist Price:

| Electric Wire Rope Hoist(t) | Lifting Height(m) | Power Supply(V) | Price(USD) |

| 1 ton | 3~50 | 220-480/3/50 | $2000~7000 |

| 2 ton | 3~50 | 220-480/3/50 | $2500~9000 |

| 3 ton | 3~50 | 220-480/3/50 | $3000~15000 |

| 5 ton | 3~50 | 220-480/3/50 | $5000~20000 |

| 10 ton | 3~50 | 220-480/3/50 | $15000~35000 |

| 15 ton | 3~50 | 220-480/3/50 | $20000~48000 |

| 20 ton | 3~50 | 220-480/3/50 | $30000~65000 |

| 35 ton | 3~50 | 220-480/3/50 | $30000~65000 |

| 50 ton | 3~50 | 220-480/3/50 | $30000~65000 |

| 80 ton | 3~50 | 220-480/3/50 | $30000~65000 |

Lifting Mechanism of Electric Wire Rope Hoist:

Lifting motor drive winding drum rotating through coupling and hollow spindle of reducer, in order to make wire rope of drum drive the hook up and down.1. Lifting Motor

- Tapered rotor three-phase asynchronous braking motors

- High starting torque, effective braking, compact structure

- Stable operation, small volume and light weight

- Safety in use, convenient maintain

- B or F class insulation, IP44, IP54 protection

- CD1 type hoist fitted with ZD type single speed motor, MD1 type hoist fitted with ZDS type double speed motor, its ratio of usual speed and low speed is 10:1.

2. Reducer

- Three-level dead axle helical gear rotating body, long service life

- Gear and the axle made by alloy steel after heat treatment, high intensity

- Box and cover made from superior cast iron, fully covered

- Great speed ratio, high accuracy

- Compact structure, silent operation, high efficiency

- Machinery oils

- Easily assemble and disassemble

3. Rope Drum

- 1. Made of cast iron or seamless steel tube, light weight, transmit the dynamic force by splines.

- 2. Coil casing made from superior cast iron, high intensity

- 3. The drum is the central part of the hoist. It connect with travelling mechanism above through balance beam, with reducer and motor both sides, and with wire rope and hook below. Installed limited guide bar equipment to the up front of the outer cover.

4. Hook

- Forge with special steel; thrust ball bearing connect with casing through hook and beam to make the hook operate freely.

- No more than 5t :single pulley hook; More than 10t: double pulley hook.

- High security, safety buckle, mousing hook

Travelling Mechanism of Electric Wire Rope Hoist:

- Consist of electric trolley, travelling reducer, travelling motor, driven trolley, etc. The mechanism do reciprocating motion through main engine driven by side plate and drum.

- The wheel tread is straight when used with box type girder or H beam.

- The wheel tread is circular arc when used with I-beam.

- Its travelling speed is 20m/min, but 30m/min is possible; if 1~5t capacity with 12m or higher lilfting height, a driven trolley is necessary

- Travelling Motor: Use tapered rotor of three-phase asynchronous braking motors. Stable starting,safe braking, can be used with reducer. B grade or F grade of insulation,closed structure,motor protection grade is IP44 or IP54

Electrical Device of Electric Wire Rope Hoist:

- Control box is rational layout,convenient for maintain

- The Control box protection grade is IP55, and have water proof

- The main power source is optional

- Safe touch line has high electrical conduction and low pressure

- Current collector has high planing speed, to ensure the sustaining power supply

- Consisted with controlling box(0.25t capacity has no it),switch button,stopper and connecting wire

- The switch button power voltage is 380v or 36v, standard product is 360v,operating the switch accords to the direction symbols on it,via the disconnector's connect and disconnect(in controlling wire) to control the hoist's moving.

- Safe and Standard Protecting Function: novoltage protection, ground protection,short-circuit protection,thermal protection,over-loading protectgion,limit protection,overcurrent protection,power-off protection

Application of Electric Wire Rope Hoist:

1. Industrial productionProduction Line Handling: Electric wire rope hoist used to move heavy equipment, raw materials or finished products within a factory to improve production efficiency.

Equipment Installation and Maintenance: Electric wire rope hoist used for lifting and positioning heavy components during equipment installation, dismantling and maintenance.

2. Building Construction

Building material lifting: Electric wire rope hoist used for lifting and transporting materials such as reinforcing steel, concrete and steel structure in high-rise buildings or large-scale projects.

Equipment Installation: Installation of large-scale equipment, such as air-conditioning units, elevator components, etc. on construction sites.

3. Warehousing logistics

Cargo handling: Electric wire rope hoist in warehouses or logistics centers for loading and unloading heavy goods, such as containers, machinery and equipment.

Automated Warehousing System: Combined with automation system to realize automated storage and handling of goods.

4. Ships and Ports

Ship repair: Electric wire rope hoist used in shipyards for lifting ship parts, such as engines, propellers, etc.

Port Handling: Electric wire rope hoist used for loading and unloading containers or other heavy goods in ports.

5. Energy Industry

Wind power equipment installation: Electric wire rope hoist used in the installation and maintenance of wind turbines, lifting and loading of wind turbine blades, towers and other components.

Power equipment maintenance: Electric wire rope hoist used in power plants or substations for lifting transformers, generators and other equipment.

6. Other fields

Stage equipment: in large-scale performances or theaters, it is used for lifting stage sets, lighting equipment, etc.

Rescue and emergency: in rescue operations, used for lifting heavy obstacles or rescue equipment.

There is no new information in this column yet