Different Types of 10 Ton Electric Chain Hoist Specification for Sale:

10 Ton Motorized Trolley Electric Chain Hoist for Sale

10 Ton Motorized Trolley Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Hook type Electric Chain Hoist for Sale

10 Ton Hook type Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Low Headroom Electric Chain Hoist for Sale

10 Ton Low Headroom Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 3-130 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Manual Trolley Electric Chain Hoist for Sale

10 Ton Manual Trolley Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 3 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton European Electric Chain Hoist for Sale

10 Ton European Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 1 to 50 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Manual Chain Hoist for Sale

10 Ton Manual Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 0.5~3.5m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Double Hook Electric Chain Hoist for Sale

10 Ton Double Hook Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height:According your demands

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Explosion-proof Electric Chain Hoist for Sale

10 Ton Explosion-proof Electric Chain Hoist for SaleCapacity: 10 Ton

Lifting height: 3/6/9/12/18 m

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Top Features to Look for in a 10 Ton Electric Chain Hoist:

When selecting a 10 ton electric chain hoist, consider the following key features:

- Load Capacity: Ensure the hoist can handle 10 tons comfortably, with a safety margin.

- Lift Height: Check the maximum lift height to ensure it meets your operational requirements.

- Lift Speed: Look for a 10 ton electric chain hoist with adjustable or suitable lift speeds for efficiency in your tasks.

- Power Supply: Confirm the 10 ton electric chain hoist’s voltage and power supply requirements to match your facility.

- Control System: Consider whether the 10 ton electric chain hoist has a wired or wireless remote control for better operation convenience.

- Safety Features: Look for built-in safety mechanisms like overload protection, emergency stop buttons, and limit switches.

- Durability: Opt for 10 ton electric chain hoist made from high-quality materials with corrosion-resistant finishes, especially for outdoor or harsh environments.

- Motor Type: Choose between different motor types based on your needs for power, efficiency, and maintenance.

- Chain Material: Ensure the chain is made from high-strength, durable materials that can withstand heavy loads.

- Ease of Maintenance: Check for features that simplify maintenance, such as easily accessible components and clear service instructions.

- Mobility: Consider whether the 10 ton electric chain hoist is fixed or portable and whether it has features for easy transport.

How to Install and Set Up Your 10 Ton Electric Chain Hoist Safely:

Installing and setting up a 10 ton electric chain hoist safely involves several critical steps. Here’s a guide to help you through the process:

- Choose the Installation Location: Ensure the location is stable and can support the 10 ton electric chain hoist’s weight and the maximum load; Consider the height of the lift and surrounding obstructions.

- Beam Trolley: Allows horizontal movement along a beam.

- Fixed Mounting: Secure the 10 ton electric chain hoist directly to a support structure; Ensure all mounting hardware is securely fastened and capable of handling the load.

- Power Supply: Connect the 10 ton electric chain hoist to the correct power supply as specified by the manufacturer (voltage and phase).

- Electrical Connections: Follow the wiring diagram in the manual. Ensure all connections are tight and properly insulated.

- Test the Control System: Verify that the remote control or pendant is functioning correctly. Test all buttons to ensure they operate the 10 ton electric chain hoist as intended.

- Load Test: Before normal operation, conduct a load test with a weight close to the 10 ton electric chain hoist’s capacity (without exceeding it) to ensure everything is functioning properly.

- Safety Checks: Double-check all connections, mounts, and rigging; Ensure that all safety features (like limit switches and emergency stops) are operational.

- Training and Safety Protocols; Train all operators on safe usage, including weight limits, proper rigging techniques, and emergency procedures.

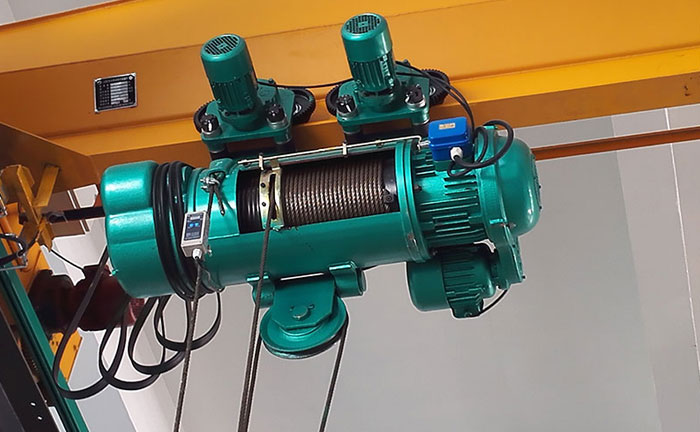

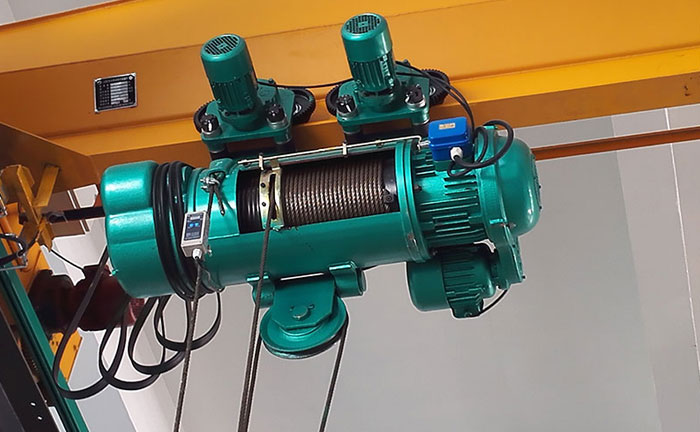

Different Types of 10 Ton Electric Wire Rope Hoist Specification for Sale:

10 Ton Single Speed Electric Wire Rope Hoist for Sale

10 Ton Single Speed Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Double Speed Electric Wire Rope Hoist for Sale

10 Ton Double Speed Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 6 to 50 m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Low Headroom Electric Wire Rope Hoist for Sale

10 Ton Low Headroom Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 3~60m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Explosion-proof Electric Wire Rope Hoist for Sale

10 Ton Explosion-proof Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 3~100m

Working Duty:M3,M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Metallurgical Electric Wire Rope Hoist for Sale

10 Ton Metallurgical Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 6~18m

Working Duty:M3

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale

10 Ton European standard Low Headroom Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 6m-50m

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale

10 Ton Single & Double Girder European Style Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height:1-120M

Working Class: M5, M6

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

10 Ton Double Hook Electric Wire Rope Hoist for Sale

10 Ton Double Hook Electric Wire Rope Hoist for SaleCapacity: 10 Ton

Lifting height: 6-100m

Working Duty:M3, M4

Power supply: 220-660V 50/60Hz 3Phase

Ambient Temperature: -25~40℃

Maintenance Tips for Ensuring Longevity of Your Electric Wire Rope Hoist:

To ensure the longevity of your 10 ton electric wire rope hoist, regular maintenance is essential. Here are some key tips:

1. Cleaning

Remove Debris: Keep the 10 ton electric wire rope hoist and surrounding area clean from dust, dirt, and debris that could interfere with its operation.

Wipe Down: Regularly clean the wire rope and components with a suitable solvent to remove contaminants.

2. Lubrication

Lubricate Moving Parts: Regularly apply lubricant to moving components such as gears, bearings, and rollers according to the manufacturer's recommendations.

Wire Rope Care: Use a wire rope lubricant to reduce friction and prevent corrosion.

3. Check Electrical Components

Inspect Cables: Look for any fraying or damage in the power cables and control pendant.

Test Controls: Ensure that all buttons and controls respond properly and there are no loose connections.

4. Examine Hooks and Rigging

Hook Inspection: Check hooks for signs of wear, deformation, or cracks. Replace if necessary.

Rigging Gear: Inspect slings, shackles, and other rigging components for wear and compatibility with the 10 ton electric wire rope hoist.

5. Environmental Considerations

Control Conditions: If possible, operate the electric wire rope hoist in a controlled environment to minimize exposure to harsh weather, chemicals, and extreme temperatures.

Corrosion Protection: Use rust inhibitors and store the 10 ton electric wire rope hoist properly when not in use.

By following these maintenance tips, you can help ensure that your 10 ton electric wire rope hoist remains in good working condition, reducing the risk of breakdowns and extending its lifespan.

Top Benefits of Using a 10 Ton Electric Wire Rope Hoist for Heavy Lifting:

- Built-in Safety Features: Many models of 10 ton electric wire rope hoist include overload protection, emergency stops, and limit switches to enhance safety.

- User-Friendly Controls: Electric hoists typically feature simple, intuitive controls that make operation easy, even for less experienced operators.

- Remote Operation: Many 10 ton electric wire rope hoist allow for remote control operation, enabling operators to manage lifts from a safe distance.

- Multi-Purpose Use: 10 ton electric wire rope hoist can be used in various applications, from construction and manufacturing to warehouses and shipping docks.

- Compatibility: They can be mounted on various structures, including beams, gantries, and A-frames, making them adaptable to different setups.

- Robust Design: Built to withstand harsh conditions, 10 ton electric wire rope hoist are typically constructed from durable materials, ensuring a long lifespan.

- Consistent Performance: Electric motors provide reliable power, ensuring consistent lifting capabilities under load.

- Accurate Positioning: 10 ton electric wire rope hoist offer fine control over lifting and lowering, allowing for precise positioning of heavy loads.

- Smooth Operation: They provide smooth and steady lifting, which is crucial when handling delicate or oversized materials.

- Reduced Maintenance Costs: Regular maintenance is straightforward, and many models have fewer wear parts compared to other lifting mechanisms.

By integrating a 10 ton electric wire rope hoist into your operations, you can enhance safety, productivity, and efficiency, making it a valuable asset for any heavy lifting task.

Different Types of Electric Hoist Price:

The electric hoist price can vary widely depending on several factors, including the hoist's capacity, brand, quality, and where you purchase it. In general, electric hoist price can range from a few hundred dollars to several thousand dollars. Here are some approximate electric hoist price ranges based on hoist capacity:

European-spec electric hoist price

European-spec electric hoist are known for their quality and safety features. European-spec electric hoist price can range from $1,000 to $5,000 or more.

Single speed wire rope electric hoist price

Single-speed wire rope electric hoist typically single speed wire rope electric hoist cost between $500 and $3,000.

Double Speed Wire Rope Electric Hoist Price

Double-speed wire rope electric hoist price higher than single-speed models and double speed wire rope electric hoist price from $1,000 to $5,000 or more.

Explosion-proof electric hoist price

Explosion-proof electric hoist are designed for hazardous environments and safety. Explosion-proof electric hoist price can vary significantly but generally range from $2,000 to $10,000 or more.

Electric chain hoist price

Electric chain hoist are often more affordable than wire rope hoist. Electric chain hoist price typically range from $300 to $2,000 or more.

Metallurgical electric hoist price

Metallurgical hoist are designed for heavy-duty applications. Metallurgical electric hoist price can range from $2,000 to $10,000 or more.

Traditional Electric Hoist Trolley price

Traditional electric hoist trolleys are often more affordable, with traditional electric hoist trolley price ranging from $300 to $1,500 or more.

European-spec Electric Hoist Trolley price

European-spec electric hoist trolleys are known for their quality and safety features and European-spec electric hoist trolleys price from $1,000 to $5,000 or more.

Cost-Effective Solutions: How a 10 Ton Electric Hoist Can Save You Money:

Investing in a 10 ton electric hoist can be a smart financial decision, as it offers various cost-effective benefits across multiple operational aspects. Here are several ways a 10 ton electric hoist can help save money:

1. Increased Efficiency

Time Savings: 10 ton electric hoist can significantly reduce the time required to move heavy loads, leading to faster project completion and turnover.

Streamlined Operations: Customization options can optimize workflows, enhancing overall efficiency in material handling and assembly processes.

2. Reduced Equipment Wear and Tear

Gentler Lifting: 10 ton electric hoist offer controlled lifting, which minimizes the risk of damage to both the load and the hoist itself, extending the lifespan of your equipment.

Lower Maintenance Costs: With fewer manual interventions and less stress on equipment, maintenance needs may be reduced, leading to cost savings over time.

3. Lower Operational Costs

Energy Efficiency: 10 ton electric hoist often have lower energy consumption compared to hydraulic or manual options, resulting in reduced energy costs over time.

Long-Term Investment: Though the initial purchase may seem significant, the long-term savings from reduced labor, maintenance, and operational costs often outweigh the upfront expense.

4. Improved Inventory Management

Faster Material Handling: Efficient lifting and moving can enhance inventory management, allowing for quicker loading and unloading of materials, leading to better stock control and reduced holding costs.

Optimized Warehouse Space: With faster movement of goods, you can maximize storage space and improve overall inventory turnover rates.

Versatile Lifting: Applications of a 10 Ton Electric Hoist Across Industries:

1. Construction

Material Handling: 10 ton electric hoist used to lift heavy construction materials such as steel beams, concrete blocks, and equipment.

Formwork and Scaffolding: Assists in assembling and disassembling scaffolding systems, improving efficiency on job sites.

2. Manufacturing

Assembly Lines: 10 ton electric hoist facilitates the movement of heavy components along assembly lines, enhancing production speed and safety.

3. Mining

Equipment Maintenance: Helps in lifting and maintaining heavy mining equipment, ensuring operational efficiency.

4. Shipping and Logistics

Container Handling: Essential for loading and unloading shipping containers at docks, increasing turnaround times.

Warehouse Operations: 10 ton electric hoist aids in moving heavy goods within warehouses, optimizing storage and retrieval processes.

5. Automotive Industry

Vehicle Assembly: 10 ton electric hoist used in assembly plants to lift car parts and frames during production.

Maintenance and Repair: Assists in lifting vehicles for servicing, enhancing safety and accessibility.

6. Energy Sector

Wind Turbine Installation: Helps lift and position heavy components of wind turbines, crucial for renewable energy projects.

Power Plant Maintenance: 10 ton electric hoist used for the maintenance and installation of heavy equipment in power generation facilities.

The versatility of a 10 ton electric hoist makes it an invaluable tool across various industries. Its ability to lift heavy loads safely and efficiently enhances productivity and safety in numerous applications, from construction to entertainment. As industries continue to evolve, the demand for 10 ton electric hoist is likely to grow, emphasizing the importance of investing in reliable lifting solutions.

Tailored Solutions: Customizing Your 10 Ton Electric Hoist for Specific Needs:

Customizing a 10 ton electric hoist can significantly enhance its performance and suitability for specific applications. Here are some tailored solutions and considerations to ensure the 10 ton electric hoist meets unique operational requirements:

1. Load Capacity Adjustments

Overload Protection: Integrate sensors that prevent lifting beyond the specified capacity, ensuring safety and preventing equipment damage.

Variable Load Handling: Consider 10 ton electric hoist with adjustable settings for different load weights, allowing flexibility for various tasks.

2. Hoist Configuration

Single vs. Double Reeving: Customize the 10 ton electric hoist configuration to suit the lifting height and load distribution, optimizing performance based on specific applications.

Suspension Types: Choose from hook-mounted, trolley, or fixed suspension options based on your workspace layout and lifting needs.

3. Environmental Considerations

Weatherproofing: For outdoor use, add protective covers and seals to guard against moisture, dust, and extreme temperatures.

Corrosion Resistance: Opt for materials and coatings that withstand corrosive environments, especially in maritime or chemical industries.

4. Safety Features

Emergency Stop Functions: Install easily accessible emergency stop buttons to ensure quick response in critical situations.

Limit Switches: Add limit switches to prevent over-travel, protecting the 10 ton electric hoist and the load from damage.

10 Ton Motorized Trolley Electric Chain Hoist for Sale

10 Ton Motorized Trolley Electric Chain Hoist for Sale 10 Ton Hook type Electric Chain Hoist for Sale

10 Ton Hook type Electric Chain Hoist for Sale 10 Ton Low Headroom Electric Chain Hoist for Sale

10 Ton Low Headroom Electric Chain Hoist for Sale 10 Ton Manual Trolley Electric Chain Hoist for Sale

10 Ton Manual Trolley Electric Chain Hoist for Sale 10 Ton European Electric Chain Hoist for Sale

10 Ton European Electric Chain Hoist for Sale 10 Ton Manual Chain Hoist for Sale

10 Ton Manual Chain Hoist for Sale 10 Ton Double Hook Electric Chain Hoist for Sale

10 Ton Double Hook Electric Chain Hoist for Sale 10 Ton Explosion-proof Electric Chain Hoist for Sale

10 Ton Explosion-proof Electric Chain Hoist for Sale 10 Ton Single Speed Electric Wire Rope Hoist for Sale

10 Ton Single Speed Electric Wire Rope Hoist for Sale 10 Ton Double Speed Electric Wire Rope Hoist for Sale

10 Ton Double Speed Electric Wire Rope Hoist for Sale 10 Ton Low Headroom Electric Wire Rope Hoist for Sale

10 Ton Low Headroom Electric Wire Rope Hoist for Sale 10 Ton Explosion-proof Electric Wire Rope Hoist for Sale

10 Ton Explosion-proof Electric Wire Rope Hoist for Sale 10 Ton Metallurgical Electric Wire Rope Hoist for Sale

10 Ton Metallurgical Electric Wire Rope Hoist for Sale 10 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale

10 Ton European standard Low Headroom Electric Wire Rope Hoist for Sale 10 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale

10 Ton Single & Double Girder European Style Electric Wire Rope Hoist for Sale 10 Ton Double Hook Electric Wire Rope Hoist for Sale

10 Ton Double Hook Electric Wire Rope Hoist for Sale