1 Ton Electric Hoist

1 ton electric hoist is equipped with a robust motor and durable hoisting mechanism, making it ideal for in industries such as manufacturing, construction, warehousing, and more. With its compact size and powerful lifting capacity, 1 ton electric hoist offers convenience, safety and reliability.

Motorized Trolley Electric Chain Hoist

Motorized Trolley Electric Chain Hoist Hook type Electric Chain Hoist

Hook type Electric Chain Hoist Low Headroom Electric Chain Hoist

Low Headroom Electric Chain Hoist Manual Trolley Electric Chain Hoist

Manual Trolley Electric Chain Hoist European Electric Chain Hoist

European Electric Chain Hoist Manual Chain Hoist

Manual Chain Hoist Double Hook Electric Chain Hoist

Double Hook Electric Chain Hoist Explosion-proof Electric Chain Hoist

Explosion-proof Electric Chain Hoist Single Speed Electric Wire Rope Hoist

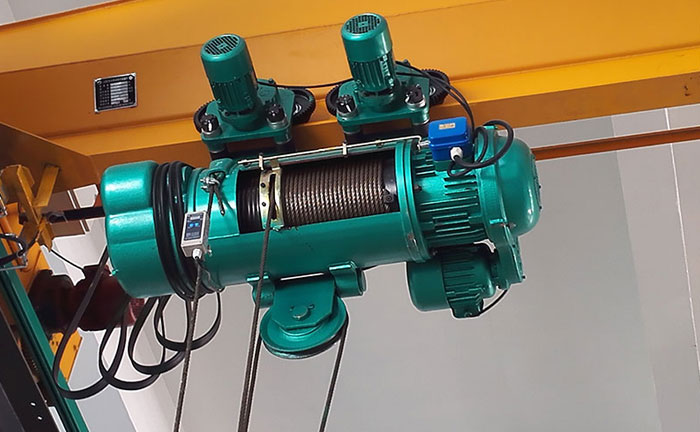

Single Speed Electric Wire Rope Hoist Double Speed Electric Wire Rope Hoist

Double Speed Electric Wire Rope Hoist Low Headroom Electric Wire Rope Hoist

Low Headroom Electric Wire Rope Hoist Explosion-proof Electric Wire Rope Hoist

Explosion-proof Electric Wire Rope Hoist Metallurgical Electric Wire Rope Hoist

Metallurgical Electric Wire Rope Hoist European standard Low Headroom Electric Wire Rope Hoist

European standard Low Headroom Electric Wire Rope Hoist Single & Double Girder European Style Electric Wire Rope Hoist

Single & Double Girder European Style Electric Wire Rope Hoist Mini Electric Wire Rope Hoist

Mini Electric Wire Rope Hoist Double Hook Electric Wire Rope Hoist

Double Hook Electric Wire Rope Hoist