Projects

Comparison of Different Types of Gantry Crane

Lifting Capacity: 1-550 ton

Span: 7.5~31.5 m

Lifting Height: 6~30 m

Working Class: A3-A7

Note: We can design and manufacture the crane according your requirments and working conditions.

A gantry crane is a versatile and mobile lifting device commonly used in various industrial settings for material handling. Unlike traditional overhead cranes, a gantry crane is mounted on legs or wheels, allowing it to move horizontally along a track or on the ground. This mobility makes gantry cranes particularly well-suited for applications where lifting and transporting heavy loads is required in different locations within a facility or across outdoor sites. Gantry cranes are utilized in diverse industries, including manufacturing, construction, shipping, and warehouses, providing an efficient and adaptable solution for lifting operations. Their design allows for customization based on specific project requirements, making them a cost-effective and versatile choice for a wide range of lifting applications.

Different Types of Gantry Crane for Choice:

Description: Featuring a single horizontal beam supported by two legs, the single girder gantry crane is a cost-effective solution for light to moderate lifting tasks.

Applications: Commonly employed in workshops, warehouses, and manufacturing facilities.

Description: Distinguished by two horizontal girders for increased stability and lifting capacity, the double girder gantry crane is ideal for heavy-duty applications.

Applications: Well-suited for tasks requiring higher lifting capacities, such as steel yards and shipyards.

Description: Known for its adjustable height and span, the portable gantry crane is designed for mobility and flexibility in temporary work environments.

Applications: Frequently used in construction sites and maintenance tasks where adaptability is key.

Description: Supported on one end, often with wheels or rails, the semi-gantry crane is designed to address spatial constraints and uneven floors.

Applications: Commonly found in outdoor construction sites and loading docks.

Description: Operating on fixed tracks, the rail-mounted gantry crane ensures precise movement, making it efficient for container handling.

Applications: Widely used in container terminals and intermodal facilities.

Description: Mounted on rubber tires, the rubber-tired gantry crane provides flexibility on paved surfaces, making it suitable for container stacking.

Applications: Predominantly found in container yards and port environments.

Description: Noted for its truss structure in the horizontal girder, the truss gantry crane offers strength and stability, especially in outdoor applications with wind loads.

Applications: Well-suited for construction sites and outdoor material handling.

Description: Characterized by its ability to adjust height, span, and tread, the adjustable height gantry crane provides versatility and adaptability to different tasks.

Applications: Ideal for workshops, maintenance tasks, and changing work environments.

Description: Featuring a horizontal girder that extends beyond supporting legs, the cantilever gantry crane is designed to access hard-to-reach areas.

Applications: Useful in outdoor construction and loading/unloading scenarios with spatial constraints.

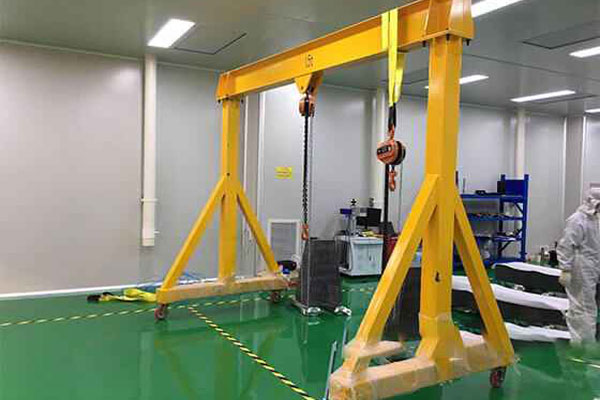

Description: Compact in size, the mini gantry crane is designed for smaller lifting tasks, offering maneuverability in tight spaces.

Applications: Commonly used in laboratories, small workshops, and other light-duty applications.

How to choosing the right gantry crane types

- Lifting Capacity: Determine the maximum weight the gantry crane needs to lift. Choose a crane with a capacity that exceeds your heaviest load.

- Span and Height: Consider the width and height of the area where the crane will operate. Ensure the crane's span and lifting height meet your requirements.

- Mobility: Decide whether a fixed or mobile gantry crane suits your needs. Adjustable gantry cranes provide mobility within a workspace.

- Controls: Choose between manual, semi-automatic, or fully automatic control systems based on your operational preferences and requirements.

- Environment: Consider the environmental conditions, such as temperature, humidity, and corrosive elements, to ensure the crane's durability and performance.

- Safety Features: Prioritize cranes with safety features like overload protection, emergency stop buttons, and collision avoidance systems.

- Power Source: Decide between electric, hydraulic, or pneumatic power sources based on energy availability and operational preferences.

- Cost of Ownership: Evaluate the initial cost, maintenance requirements, and operational costs to determine the overall cost of ownership.

Gantry cranes offer several advantages in material handling and lifting operations:

- Versatility: Suitable for diverse industries and applications.

- High Load Capacity: Capable of lifting and moving heavy loads efficiently.

- Span and Height Adjustability: Configurable to meet specific project requirements.

- Mobility: Equipped with wheels or tracks for easy movement around a worksite.

- Cost-Effective: Generally more economical compared to some other lifting solutions.

- Ease of Installation: Quick and straightforward installation without complex support structures.

- Improved Safety: Equipped with safety features and offers better operator visibility.

- Customization Options: Can be tailored with specialized features for specific applications.

- Quick and Efficient Material Handling: Enables rapid lifting, moving, and positioning of loads.

- Accessibility: Provides access to different areas within a facility or worksite.

Gantry Crane vs. Overhead Crane: Which Is Right for You?

The choice between a gantry crane and an overhead crane depends on various factors related to your specific needs, facility layout, and operational requirements. Here's a comparison to help you determine which type of crane may be right for you:

Gantry Crane:

1. Mobility:

Advantage (Gantry): Gantry cranes are mobile and can be moved around the worksite as needed, making them suitable for outdoor applications and versatile in various settings.

2. Support Structure:

Advantage (Gantry): Gantry cranes do not require a building structure for support. They can be self-supporting with legs or wheels, which simplifies installation and reduces the need for additional construction.

3. Cost:

Advantage (Gantry): Gantry cranes are often more cost-effective, especially when there is no existing building structure to support an overhead crane.

4. Flexibility:

Advantage (Gantry): Gantry cranes are flexible in terms of height and span adjustments, providing adaptability to various project requirements.

5. Outdoor Use:

Advantage (Gantry): Gantry cranes are well-suited for outdoor applications, such as construction sites, shipyards, or open-air storage yards.

Overhead Crane:

1. Precision and Stability:

Advantage (Overhead): Overhead cranes typically offer higher precision and stability due to their fixed nature. They are suitable for tasks requiring exact positioning.

2. Height Clearance:

Advantage (Overhead): Overhead cranes do not have ground-level obstacles, providing better height clearance for lifting operations within a facility.

3. Lifting Height:

Advantage (Overhead): Overhead cranes are ideal for lifting operations that require significant height, as they can be installed to utilize the full vertical space of a facility.

4. Indoor Use:

Advantage (Overhead): Overhead cranes are typically used indoors within existing buildings, making them suitable for manufacturing facilities, warehouses, and assembly lines.

5. Capacity:

Advantage (Overhead): Overhead cranes can often handle heavier loads and have higher lifting capacities compared to some gantry crane configurations.

Considerations:

- Space and Layout: Consider the layout of your facility and the available space. Overhead cranes are suitable for facilities with sufficient height, while gantry cranes are more adaptable to varying spatial constraints.

- Mobility Requirement: If you need a crane that can be easily moved to different locations, especially outdoors, a gantry crane may be more suitable.

- Budget: Assess your budget constraints. Gantry cranes are often more cost-effective for certain applications, but overhead cranes may be a better long-term investment for specific indoor settings.

- Operational Needs: Consider the specific lifting requirements, precision, and operational characteristics crucial for your application.