Projects

Different Types of Gantry Crane for Sale

Lifting Capacity: 1-550 ton

Span: 7.5~31.5 m

Lifting Height: 6~30 m

Working Class: A3-A7

Note: We can design and manufacture the crane according your requirments and working conditions.

Gantry crane is a type of crane that is typically used to lift and move heavy objects within a defined area. It gets its name from the horizontal gantry structure that supports the lifting mechanism. Gantry crane for sale are commonly used in industrial and commercial settings, such as warehouses, shipping yards, construction sites, and manufacturing facilities, where they are needed to handle heavy and bulky materials.

Gantry crane for sale come in various sizes and configurations to suit the specific needs of the application. They can be mobile or stationary, and their lifting capacity can range from a few tons to several hundred tons, depending on the design and purpose.

Gantry crane are commonly used for tasks like loading and unloading shipping containers, moving heavy machinery in factories, and assembling large structures. They offer flexibility, efficiency, and the ability to handle heavy loads with precision, making them an essential tool in many industries.

Key features and components of gantry crane for sale:

- Gantry Structure: This is the framework or structure that spans the area over which the crane operates. It consists of horizontal beams or legs on which the crane moves. The design of the gantry structure can vary, with some crane having single legs (semi-gantry) and others having double legs (full gantry).

- Lifting Mechanism: Gantry crane are equipped with a hoist or lifting mechanism that can be either manual, electric, or hydraulic. This mechanism is responsible for raising and lowering the load.

- Runway Rails: Gantry crane typically move along rails or tracks that are installed on the ground. The crane's wheels or trolleys run on these rails, allowing it to travel back and forth.

- Control System: Gantry crane can be operated manually or remotely through a control system. Some modern gantry crane feature advanced automation and computerized controls for precise positioning and load management.

Different types of gantry crane for sale specifications:

Single Girder Gantry Crane for Sale Specification:

- Lifting capacity: 1-25t

- Lifting span(m): 7.5~31.5

- Lifting height(m): 6~30m

- Power supply(V): 220-480/3/50

- Price(USD): $5,000 - $250,000

Double Girder Gantry Crane for Sale Specification:

- Lifting capacity (T): 1-100t

- Lifting span: 7.5~31.5

- Lifting height: 6~30

- Power supply(V): 220-480/3/50

- Price(USD): $50,000 - $1,000,000

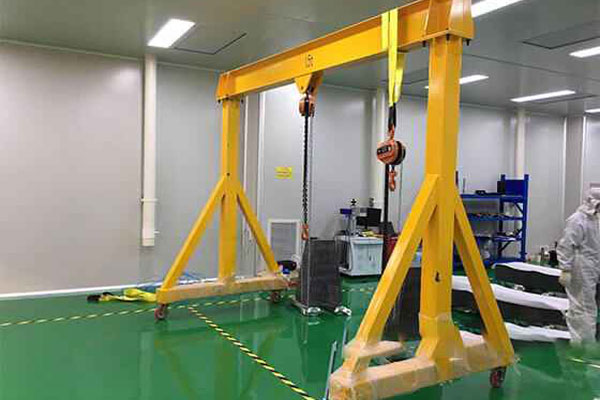

Portable Gantry Crane for Sale Specification:

- Lifting capacity: 0.25-20t

- Lifting span(m): 2~12

- Lifting height(m): 1~9m

- Power supply(V): 220-480/3/50

- Price(USD): $500 - $20,000

Semi-Gantry Crane for Sale Specification:

- Lifting capacity (T): 1-20t

- Lifting span: 10-20

- Lifting height: 1-30

- Power supply(V): 220-480/3/50

- Price(USD): $5,000-$75,000

Rail-Mounted Gantry Crane (RMG) for Sale Specification:

- Lifting capacity: 25~100t

- Lifting span(m): 7.5~31.5

- Lifting height(m): 6~30

- Power supply(V): 220-480/3/50

- Price(USD): $500,000 - $5,000,000

Rubber-Tired Gantry Crane (RTG) for Sale Specification:

- Lifting capacity (T): 20-100t

- Lifting span: 20~30

- Lifting height: 12~18

- Power supply(V): 220-480/3/50

- Price(USD): $2,00,000 - $1,000,000

Truss Gantry Crane for Sale Specification:

- Lifting capacity: 1-100t

- Lifting span(m): 12~35

- Lifting height(m): 6~18

- Power supply(V): 220-480/3/50

- Price(USD): $10,000 - $500,000

Adjustable Height Gantry Crane for Sale Specification:

- Lifting capacity (T): 0.5-10t

- Lifting span: 2~12

- Lifting height: 1~9

- Power supply(V): 220-480/3/50

- Price(USD): $2,000 - $50,000

Cantilever Gantry Crane for Sale Specification:

- Lifting capacity: 3-200t

- Lifting span(m): 18~35

- Lifting height(m): 6~12m

- Power supply(V): 220-480/3/50

- Price(USD): $15,000~$800,000

Mini Gantry Crane for Sale Specification:

- Lifting capacity (T): 0.5-10t

- Lifting span: 3-9

- Lifting height: 1-6

- Power supply(V): 220-480/3/50

- Price(USD): $2,000-$20,000

Safety protection system of Gantry Crane:

The safety protection system of a gantry crane for sale is a critical component to ensure the safe operation of the crane, protect personnel and equipment, and prevent accidents. The safety protection system includes various mechanisms and features designed to monitor and control the crane's operation. Here are some key elements of a typical gantry crane safety protection system:

- Overload Protection: Gantry crane for sale are equipped with overload protection systems that monitor the weight being lifted. If the crane exceeds its rated capacity, the system will activate an alarm and, in some cases, automatically stop the crane's operation.

- Emergency Stop Button: Gantry crane are equipped with emergency stop buttons located in easily accessible areas. Pressing this button instantly halts all crane movement in case of an emergency or when an unsafe condition is detected.

- Limit Switches: Limit switches are used to define the maximum and minimum travel limits for the crane along the runway. When these limits are reached, the switches trigger actions such as stopping the crane to prevent overtravel.

- Collision Avoidance Systems: Modern gantry crane may have collision avoidance systems, which use sensors and/or cameras to detect obstructions in the crane's path. If an obstacle is detected, the crane will stop or slow down to avoid collisions.

- Anti-Sway Systems: These systems help reduce load swinging or swaying when lifting or moving heavy loads. They use sensors and controls to minimize load sway and maintain stability during lifting.

- Emergency Lowering System: In case of a power failure, an emergency lowering system allows the operator to lower the load safely to the ground.

- Warning Alarms and Lights: Gantry crane are often equipped with warning alarms and flashing lights to alert personnel in the vicinity when the crane is in operation.

Gantry Crane Maintenance : Keeping Your Crane in Top Shape

Maintaining a gantry crane is essential for its safe and efficient operation. Regular inspections and maintenance can help prevent accidents and extend the crane's lifespan. Here's to help you keep your gantry crane in top shape:

Daily Inspections:

- Visual Inspection: Look for any signs of damage, wear, or loose components. Check for leaks or unusual sounds.

- Wire Ropes or Chains: Inspect the condition of wire ropes or chains for signs of wear, kinks, or broken strands. Ensure they are properly lubricated.

- Limit Switches: Test the limit switches to ensure they stop the crane at the correct positions.

- Emergency Stop Button: Make sure the emergency stop button is functional and easily accessible.

- Structural Components: Examine the main beams, frames, and support structures for any cracks, rust, or deformities.

- Electrical Systems: Check control panels, wiring, and connectors for signs of wear, loose connections, or damaged components.

- Brakes: Test the brake systems to ensure they engage and release properly.

Periodic Inspections:

- Wheels and Rails: Inspect the wheels, rails, and their alignment. Ensure there are no obstructions or debris on the rails.

- Trolley and Hoist: Examine the trolley and hoist mechanisms for smooth and correct operation. Lubricate moving parts as needed.

- Safety Devices: Test all safety devices, such as anti-sway systems, to make sure they are functioning correctly.

- Load Testing: Conduct load tests to ensure the crane can handle its rated capacity. Document the results.

- Bolts and Fasteners: Inspect all bolts and fasteners for tightness and signs of corrosion.

- Electrical Controls: Check the control system for correct voltage, amperage, and functionality.

- Replacement Parts: Replace worn-out components, such as wire ropes, sheaves, and hooks, as needed.

Which crane do you need: gantry crane OR overhead crane?

Gantry crane and overhead crane are both types of material handling equipment used for lifting and moving heavy objects, but they differ in several ways, including their structure, mobility, and application. Here are the main differences between a gantry crane and an overhead crane:

1. Support Structure:- Gantry Crane: Gantry crane have a visible, ground-based support structure that consists of two vertical legs and horizontal beams, often resembling a large "A" or "H" shape. The support structure is independent of the building's framework and stands on the ground. Gantry cranes can be either full gantry (with two vertical legs) or semi-gantry (with one vertical leg).

- Overhead Crane: Overhead crane, also known as bridge crane or suspended cranes, are supported from the ceiling or overhead structure of a building. They have a single or double girder that runs along an overhead runway, and the hoist or lifting mechanism is attached to this girder. Overhead cranes do not have a ground-based support structure.

- Gantry Crane: Gantry cranes are mobile and can move along tracks or runways on the ground. This mobility allows them to cover a larger area, and they can be relocated to different parts of a facility as needed.

- Overhead Crane: Overhead cranes are fixed in place, moving only along the overhead runway system. They are limited to the area covered by the runway, which can be customized to suit the specific needs of the facility.

- Gantry Crane: Gantry cranes require open floor space to accommodate the legs and runway tracks. They are suitable for outdoor applications or in areas where floor space is available.

- Overhead Crane: Overhead cranes do not occupy floor space, which makes them more suitable for facilities where floor space is limited or needs to be kept clear for other operations. They are often used in industrial buildings, warehouses, and manufacturing facilities.

- Gantry Crane: Gantry cranes are versatile and commonly used for outdoor tasks like loading and unloading shipping containers, construction sites, and large assembly operations. They are also used in indoor settings for applications that require their mobility.

- Overhead Crane: Overhead cranes are typically used indoors for applications that require precision and control, such as manufacturing, assembly lines, and material handling within warehouses. They are ideal for lifting and moving heavy loads within a fixed area.

- Both gantry and overhead cranes can be designed to handle a wide range of lifting capacities, from a few tons to several hundred tons, depending on the specific requirements of the application.

In summary, the main differences between a gantry crane and an overhead crane are their support structure, mobility, space utilization, application, and where they are typically used. The choice between the two depends on the specific needs and constraints of a given material handling task and facility.