2 Ton Overhead Crane

2.5 Ton 20 meters Double Girder Overhead Crane for Sale to Qatar

Lifting Capacity: 2.5 ton

Span: 20 m

Lifting Height: 6.5 m

Working Class: A5

Note: We can design and manufacture the crane according your requirments and working conditions.

2.5 Ton 20 meters Double Girder Overhead Crane for Sale to Qatar:

We recently welcomed esteemed guests from Qatar to our factory premises. The purpose of their visit was to explore potential collaboration opportunities for double girder overhead crane projects. Among the various offerings, the focus of discussion gravitated towards a specific project involving a 2.5 Ton double girder overhead crane.

The client from Qatar presented us with precise specifications for the 2.5 Ton overhead crane:

- Lifting Capacity: 2.5 Ton

- Span: 20 meters

- Lifting Height: 6.5 meters

- Working Duty: A5

- Voltage: 380V, 50Hz, 3 Phase

- Location: Indoor facility

We commenced the engagement by providing a comprehensive overview of our company's history and production capabilities in the conference room. Our emphasis on quality, innovation, and reliability resonated deeply with the Qatar visiting delegation.

Delving deeper into the project specifics, we engaged in detailed discussions to ensure that the design of the 2.5 ton double girder overhead crane perfectly aligned with the client's requirements for their existing workshop.

A pivotal moment in the engagement was the tour of our overhead crane manufacturing workshop. The Qatar client witnessed firsthand the precision welding, meticulous assembly processes, and rigorous quality control measures in place. Their inquiries regarding welding techniques, assembly procedures, and shipment logistics were met with thorough explanations, fostering a deep sense of satisfaction with our manufacturing capabilities.

A highlight of the visit was the demonstration of our auto-welding line, showcasing our unwavering commitment to quality assurance. The Qatar client's confidence in the reliability and durability of our products was significantly bolstered, laying the foundation for a long-term partnership based on trust and mutual respect.

In addition to the main focus on the 2.5 ton double girder overhead crane, the Qatar client also had the opportunity to explore our range of 1-100 ton steel wire rope electric hoists.

Installation of 2.5 Ton Overhead Crane:

- Site Assessment: Evaluate the installation site to ensure it can support the 2.5 ton overhead crane's weight and dimensions. Check for adequate clearance, proper flooring, and overhead obstructions.

- Foundation: Construct a sturdy foundation capable of supporting the 2.5 ton overhead crane and its load. The foundation should be level, stable, and comply with local building codes.

- Structural Support: Install support structures, such as runway beams and columns, according to the bridge crane manufacturer's specifications. Ensure proper alignment and anchoring for stability.

- Electrical Setup: Arrange for electrical supply to power the 2.5 ton overhead crane. Install appropriate wiring, controls, and safety devices in accordance with electrical codes and regulations.

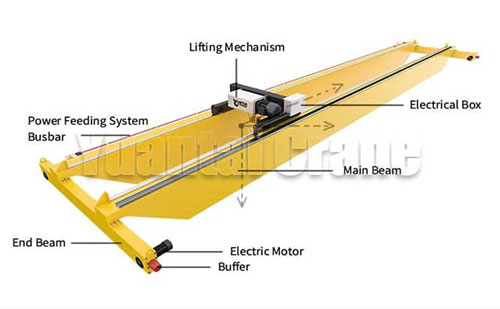

- Assembly: Assemble the 2.5 ton overhead crane components, including the bridge, hoist, trolley, and end trucks, following the manufacturer's instructions. Use proper lifting equipment and techniques during assembly.

- Testing and Commissioning: Conduct thorough testing of the bridge crane's functionality and safety features before putting it into operation. Verify proper operation of controls, limit switches, brakes, and emergency stop systems.

- Training: Train operators and maintenance personnel on safe operating procedures, maintenance tasks, and emergency protocols.

Maintenance of 2.5 Ton Overhead Crane:

- 1. Regular Inspections: Perform routine visual inspections of the 2.5 ton overhead crane, focusing on structural components, electrical connections, and moving parts. Look for signs of wear, damage, or corrosion.

- Lubrication: Keep all moving parts properly lubricated to reduce friction and prevent premature wear. Follow the manufacturer's recommendations for lubricants and lubrication intervals.

- Adjustments: Periodically check and adjust components such as brakes, limit switches, and alignment to maintain optimal performance and safety.

- Electrical Checks: Inspect electrical wiring, connections, and controls for signs of damage or deterioration. Test safety devices and emergency stop systems regularly.

- Load Testing: Conduct load tests periodically to verify the 2.5 ton overhead crane's capacity and stability under normal operating conditions.

- Repairs: Promptly address any issues or malfunctions identified during inspections or operation. Replace worn or damaged components as needed, and ensure repairs are performed by qualified personnel.

Operating a 2.5 Ton Overhead Crane Safely:

Operating a 2.5 ton overhead crane safely requires not only adherence to safety protocols but also maximizing efficiency to improve productivity and minimize downtime. Here are some tips to achieve both safety and efficiency:

- Pre-Operational Checks: Conduct thorough pre-operational checks before using the 2.5 ton overhead crane. Inspect the crane for any signs of damage, malfunction, or obstruction. Check controls, brakes, limit switches, and safety devices to ensure they are functioning correctly.

- Communication: Establish clear communication protocols between the crane operator and ground personnel. Use hand signals, radios, or other communication devices to coordinate movements and ensure everyone is aware of the operation.

- Optimal Speeds: Operate the crane at optimal speeds to maximize efficiency without compromising safety. Avoid abrupt starts and stops, and use smooth, controlled movements when positioning loads.

- Proper Positioning: Position the crane and the load carefully to minimize the need for repositioning. Plan the lift path to avoid obstacles and ensure adequate clearance. Use spotter assistance if necessary to guide the operator during complex maneuvers.

- Emergency Preparedness: Train operators and personnel in emergency procedures, including how to respond to power failures, equipment malfunctions, and accidents. Keep emergency stop buttons and other safety devices easily accessible.

Application of 2.5 Ton Double Girder Overhead Crane in Qatar:

- Construction Sector: Qatar has been undergoing extensive construction projects in preparation for major events. The 2.5 Ton Double Girder Overhead Crane finds widespread application in construction sites for tasks such as lifting and moving heavy materials like steel beams, concrete panels, and construction equipment.

- Industrial Development: Qatar has been diversifying its economy beyond oil and gas, with a focus on developing various industries such as petrochemicals, manufacturing, and logistics. The 2.5 ton overhead crane by facilitating material handling operations within manufacturing plants, warehouses, and logistics hubs.

- Port and Maritime Industry: Qatar boasts modern ports and maritime infrastructure, supporting its position as a key hub for trade and commerce in the Gulf region. The 2.5 Ton Double Girder Overhead Crane is utilized in port facilities for loading and unloading cargo containers, heavy machinery, and other goods from ships to storage yards .

- Energy Sector: The 2.5 ton overhead crane finds application in the energy sector for tasks like installation and maintenance of solar panels, wind turbines, and other renewable energy infrastructure.

- Manufacturing and Warehousing: Qatar is fostering the growth of its manufacturing sector. The 2.5 Ton Double Girder Overhead Crane serves manufacturing facilities and warehouses by facilitating efficient movement and storage of raw materials, semi-finished products, and finished goods.